Large Graphite Ferrules > PDF |

|

Standard |

> Swagelok SPECS re DIMS generally |

|

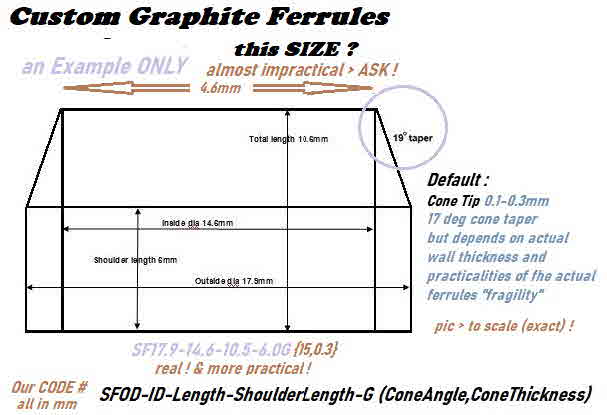

Customised |

SFOD-ID-L-SL-G ( “ +detail ? ” ) |

|

Large |

Graphite / Teflon (ONLY !) others cost prohibitive > but ASK ! |

|

OUR Standard > Swagelok Fittings ( “typical” DIMs ) |

||||||||

|

Imperial (in) |

Metric (mm) |

|||||||

|

where “100” |

=1/16” |

Actual OD |

/L |

/SL |

some Dims Actual/Typical |

ActualOD |

/Lmm |

/SL |

|

|

|

|

|

|

SFM4-G |

6.3 |

6.4 |

3.7 |

|

SF400PI |

1/4”ID |

0.373 |

0.283 |

0.110 |

|

|

|

|

|

SF400G |

|

0.384 |

0.268 |

0.120 |

|

|

|

|

|

SF600G |

3/8” ID |

|

|

|

SF400/M6G |

|

|

|

|

SF800G |

1/2” |

|

|

|

SFM8G |

|

|

|

|

SF1000G |

5/16” |

|

|

|

SFM10.6G(.3.4.5) |

13.5 |

8.3 |

4.6 |

|

SF1200G |

3/4” |

|

|

|

SFM12G |

|

|

|

|

SF1400G |

7/8” |

1.15 |

0.40 |

0.18 |

SFM14G(.6) |

17.8 |

(10.0)” |

|

|

SF1600G |

1.0” |

1.25” |

0.39” |

0.18 |

SFM16G |

|

|

|

|

SF2000G |

1-1/4” |

1.475 |

0.55 |

0.26 |

SFM20G |

|

|

|

|

SF2400G |

1-1/2” |

1.87 |

0.79 |

|

SFM25G |

30.0 |

10.2 |

4.9 |

|

SF2800G |

1-3/4” |

|

|

|

SFM28G |

|

|

|

|

SF3000G |

1-7/8” |

|

|

|

SFM32G |

42.18 |

18.62 |

|

|

SF3200G |

2.0” |

2.56 |

1.05 |

0.30 |

|

? but to be confirmed |

||

|

( Imperial Swagelok ) |

|

actual ODn”/in |

L |

SL |

{ Metric |

actual ODmm |

L |

SL |

|

large GFs (1-1//2-2”ID ) we are recommending using a SL metal backing Ferrule (yours), L can be easily adjusted to suit > Now(2022+) as our Standard ! |

||||||||

|

|

SF2.56/2.00/1.05/0.30/(0.07)-G |

|

|

|

|

|||

|

Imperial +/- in / ” Tolerance |

+0.002 |

-0.002 |

0.005 |

0.005 |

Overall Length |

|

|

|

|

NO Tooling Costs Apply for “Standard” Ferrules . . . |

||||||||

|

||||||||

|

AND WE were the “prime” Inventor of GFs for Chromatogtaphy Use ! |

||||||||

|

Small GFs : Ferrules in General |

Large GFs PDF |

|

Large GFs >10mm * Custom Tooling Cost > |

We will ask firm order(er)s to specify / verify the exact DIMs preferred and * for YOUR “DIM” Inaccuracies ? |

|

some |

|

|

In Fact |

The UNIVERSAL Ferrule for many APPS

|

|

for OPTIMUM Performance > Use OUR recommended SPECs |

|

> THE Perfect “Universal“ Ferrule material ! |

Packaging Options & some Pics CT > Large Graphite Ferrules

|

Ferrules &Nuts-Chrom > PIC Gallery > GOOGLE SEARCH PIcs > PDF LINKs

|

GF Tooling Cost ONLY IF NOT in Stock in Melbourne |

CT Chromatogrphy > PIC Gallery > via the “courtesy” of

|

|||||||||||||

|

|

|

|

|

|||||||||

|

We’d Welcome YOUR e-Mail /chat > Response . . . but YOUR “Hi-TECH“ Feedback” is also welcome |

! |

|

|

||||||||||

|

m4 / PC but |

conserve “speed” |

|

FlipHTML5 |

|

|

Chromtech.net.au > Chromtech-AUS.com > Chromalytic.net.au |

mini-SHOPPE proto-Shop2CT > “OUR Consensus”> CC < GW & Energy BLOGs |

|

NEW 2023-10 |

> Add Bing Search Bar |

* multi-Word “Step”Search & Much Improved Over

|

|

& even BETTER |

|

> very “Useful” ! |

|

|

|

||||

|

|||||

|

11-2022 FlipHTML5 |

|||||

|

|||||

|

|||||

|

|

> HTM |

||||

|

NEW SITE |

|||||

|

*results? > mainly |

|||||

|

|

|||||

|

> View OUR ! WIX Site4 a More ” optimal “ Device > |

|||||

|

|||||

|

CT-FlipHTML5 > 2019 |

|||||

|

New 2021 CHROMTECHs |

|||||

|

CT-INTRO |

|||||

|

Ctrl+F |

|||||

|

“X” - filename |

|||||

|

Mals Cart |

||||

|

On a Mobile |

||||