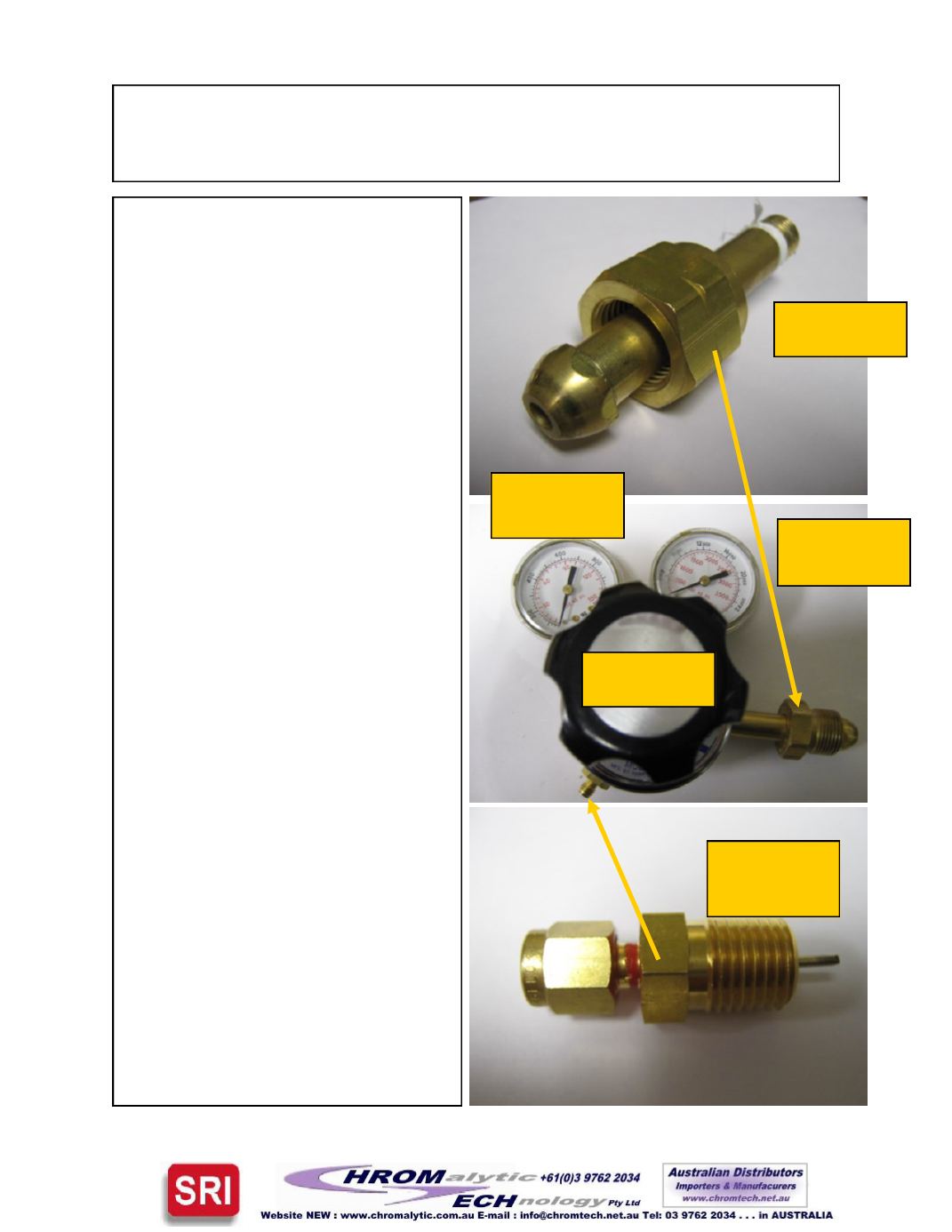

ConnectingGasCylinders

The nuts fit onto the “nipple” of the regula-

tor in order to provide a gas

-

tight seal be-

tween the tank of carrier gas and the regu-

lator. The seal ismade by the round bulb

-

like projectionwhich fits intoa correspond-

ing recess in the top of the gas cylinder.

The threaded end of the nipple screws in-

to the regulator body. The nut and nipple

must match ( have the same CGA num-

ber ).

The cylinder regulator has two pressure

gauges. The right hand gauge shows the

pressure remaining in the cylinder. This

can be as high as 2500psi when the cylin-

der is full. The cylinder should be re

-

filled

when the pressure falls to 200 psi. Don’t

let the cylinder become totally empty since

this will let ambient air contaminate the

inside surfaces. The left hand gauge

shows the reduced pressure supplied to

the outlet of the regulator. This is typically

a pressure of 15

-

90 psi. The knob adjusts

the pressure. Set the cylinder output

pressure 10

-

20 psi higher than the pres-

sure set on the GC. So if the carrier gas

pressure is set to 20 psi using the built

-

in

pressure regulator inside the GC, set the

cylinder output pressure to35

-

40psi.

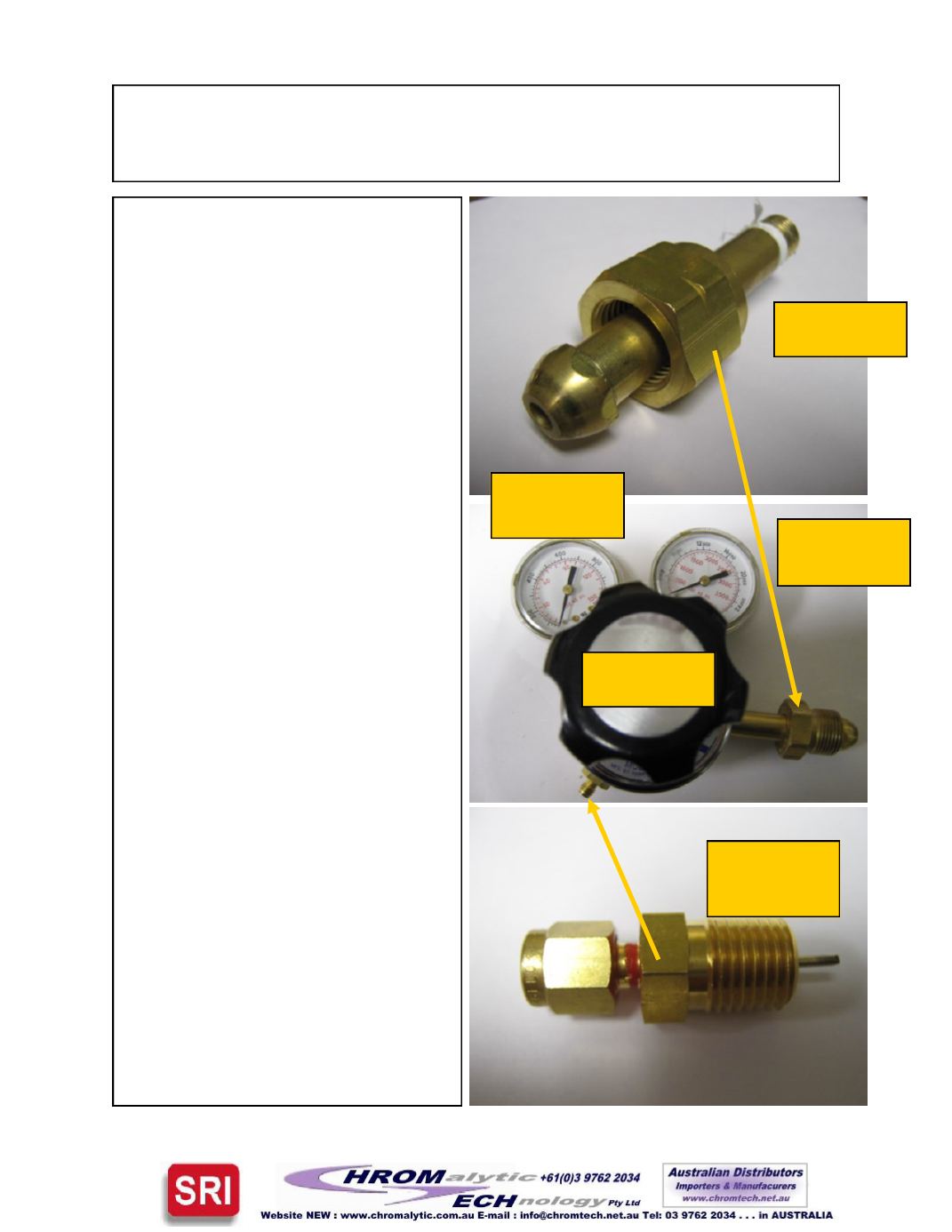

Regulators used for flammable gases

such as hydrogen or argon/methane

should be equipped with a “snubber” for

safety reasons. The snubber restricts the

flow so that in the event of a total leak

( tubing breaks ) the amount of gas re-

leased is reduced. The snubber fitting has

a very small hole for the gas to pass

through ( .1mm ). Since theGC only uses

small amounts of flammable gas ( 20

-

50

ml/minute ), there is no need for a large

flow rate.

Page2

Nut andnipple

Highpressure

gauge—cylinder

pressure

Lowpressure

gauge—regulator

pressure

Adjustment

knob

Snubber screws

intooutlet fitting

to restrict flow