CuttingTubing for SRI GCs

The shape of the hole for the carrier and

detector ( hydrogen, air, etc ) gas tubing

which runs from the gas cylinders to the

GC is not as critical as it is for other tub-

ing connections inside theGC. As long

as the hole isopenand generally circu-

lar it will not prevent good gas chroma-

tography.

1/8” stainless steel tubing

can also be

used to connect carrier gas to theGC,

but this is not recommended because it

is sohard toworkwith. There isno ad-

vantage to using stainless steel and it is

muchmore expensive than 1/8” copper.

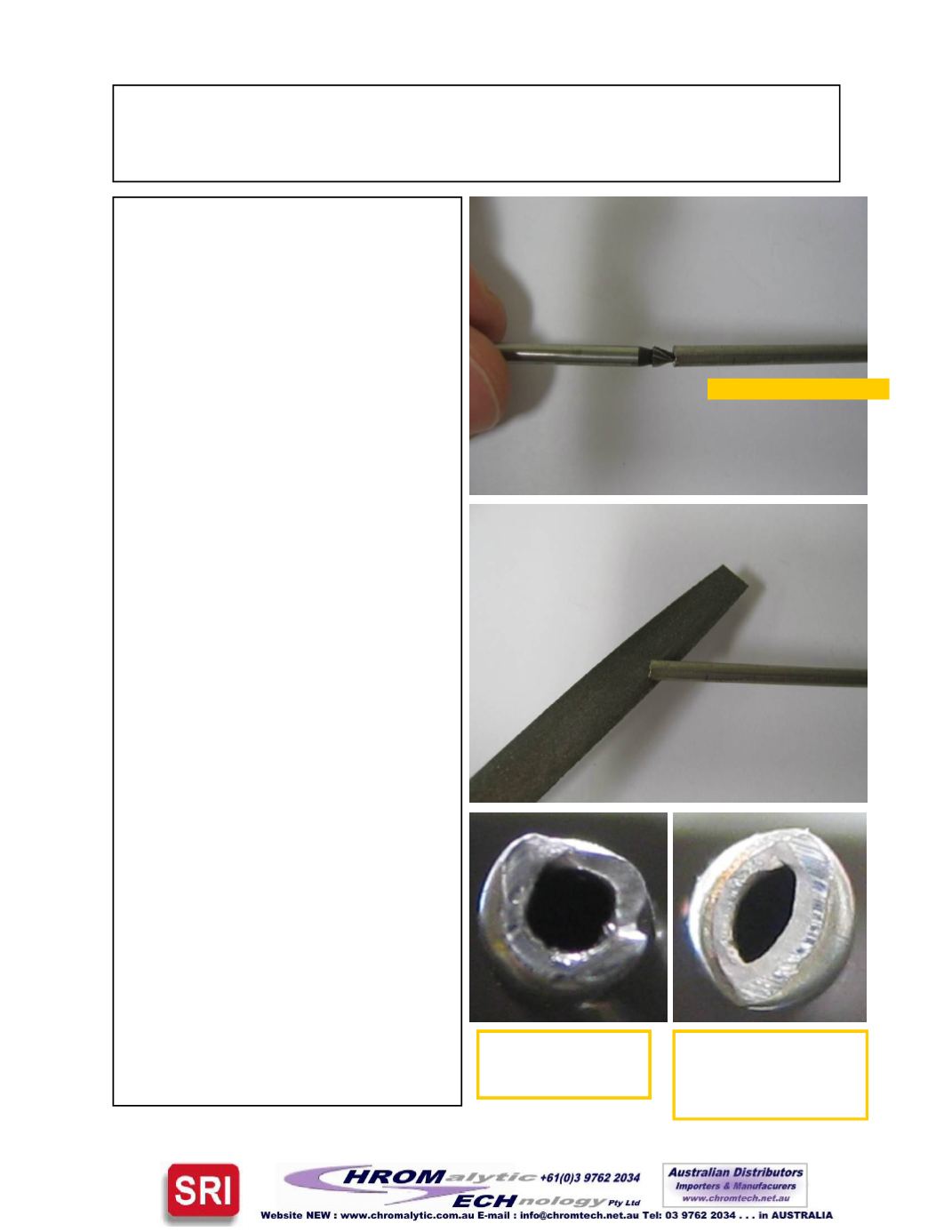

If you insist onusing stainless steel tub-

ing, youmust use a cuttingwheel to cut

it. TheSRI tubing cutter cannot cut 1/8”

stainless. Use a de-burring tool toopen

up the internal hole andametal file to

smooth any sharp edges ormetal

shards. Get ridof theparticles so they

don’t enter theGC.

1/16” ( .067 ) stainless steel tubing

is

used to plumb valvesand connect col-

umns in the column oven, andmay also

be used to connect gases to theGC.

This type of tubing comes in various in-

ternal diameters. .040” ( 1mm ) id is the

most common size. Internal diameters

smaller than .030” are too small tobe

used as supply gas tubing, but may be

used inside theGC to connect columns

and valves. When used inside theGC in

areaswhere the sample passes through

the tubing it is important to get the clean-

est cut and roundest hole to avoid vor-

texes and dead volumeswhichmight

affect thepeak shapes.

Page3

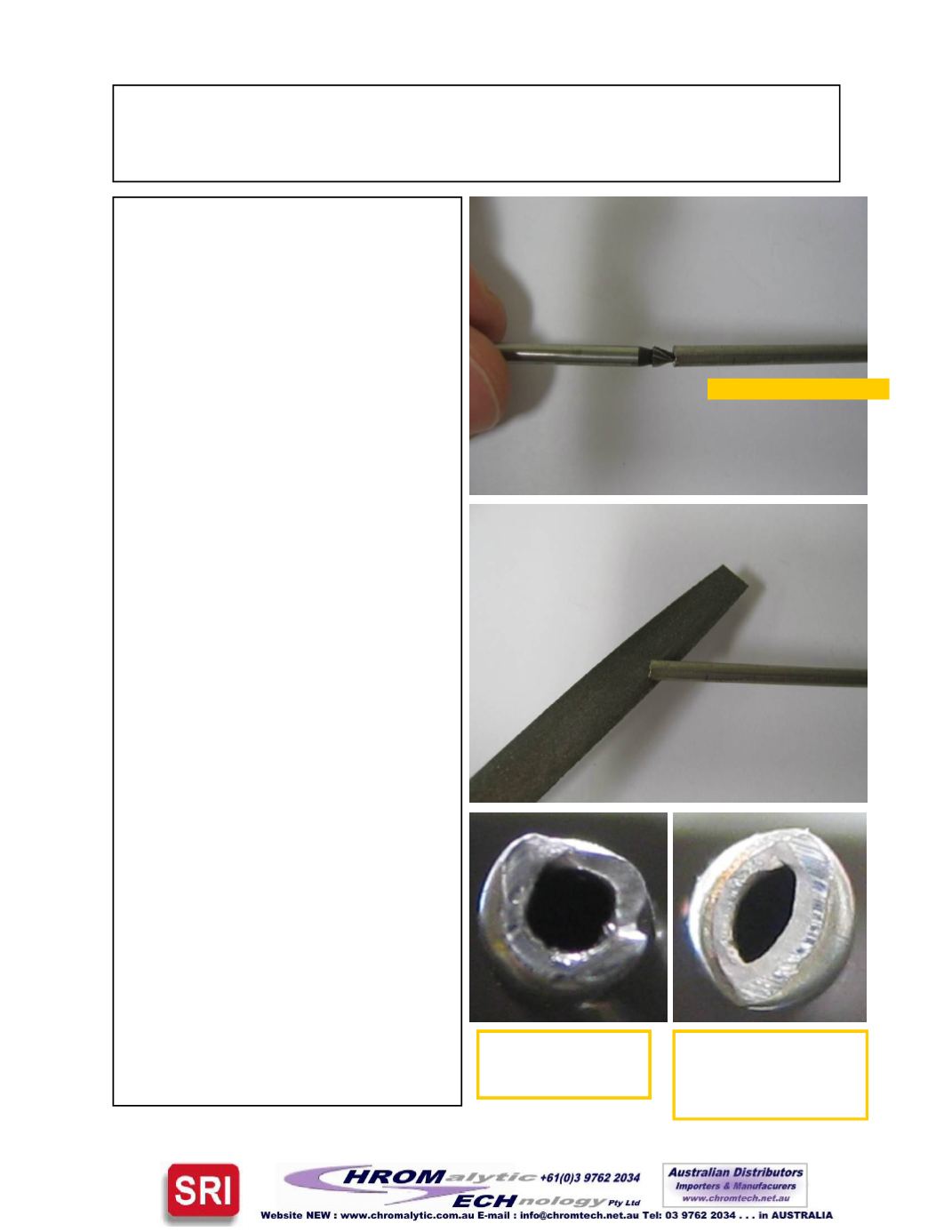

1/16” stainless steel

tubing cut well. Notice

the roundhole.

In this cut thehole is

smashed intoanoval.

Ferrulesmay not even fit

onto this tubing.

(1)

1/8” stainless tubing