2

ExperimentalDetails

Adsorbents Tested

We tested twenty-four different adsorbents. Carboxen(s),

CarbosieveS-III,andCarbopack(s)areexclusive toSupelcoand

havebeenused in the fieldof thermal desorptionandpurgeand

trap for years.We also chose adsorbents such as Tenax, silica

gel, and glass beads because of their traditional use in the field

of thermal desorption. Porapak

®

, Chromosorb

®

and HayeSep

®

arealsoused insome thermal desorptionapplications.Coconut

and petroleum charcoal predominately have been used for

solvent desorptionapplications, but someuses of thesemateri-

als do exist in thermal desorption applications.

For this research, onlyone lot per adsorbent was tested.

Table1

shows the listofadsorbents testedand thephysical propertiesof

theadsorbentssuchas themeshsize, packingdensity, andbed

weights.

AnalytesUsed as theTest Probe

Theanalyteschosenas testprobes for this researchareasubset

of the EPA Hazardous Pollutant list, and are also common to

many industrial hygiene samplingmethods.We used a gasmix

containing the 43 analytes listed in

Table 2

. Thismix contained

a broad spectrum of volatile organic analytes with physical

properties that range from (50 to 260) inmolecular weight, and

(-30 to 215°C) in boiling point. The gas mix is available as a

Supelco stock product Catalog #500429. The concentration of

each analyte in the gas mix is 1000ppb. We introduced a 20-

milliliter undiluted volume of this gas mix to each adsorbent.

(

Table2

shows thecalculatedmassofeachanalytecontained in

the 20mL volume).

Wechose thegasmix forseveral reasons.First, theanalytesare

in the gas phase to simulate a real world sample. Second, if we

haduseda liquidsolventmix, suchasmethanol, it couldalter the

resultsbecause it toomayoccupy theporesitesof theadsorbent.

Thiscouldcreateacompetition forsorptionsiteswith theanalytes

of the test mix. Third, the use of a solvent would interfere in the

detection of the very volatile analytes. This is due to the chro-

matographicconditions thatwechose tooptimize the transfer of

the analytes to the capillary column.

AnalyticalEquipment

Thermal Desorber

GERSTEL

®

loaned the thermal desorptionunit used in thisstudy

toSupelco. TheGERSTELTDSA, shown in

Figure1,

provided

the means to automate the analysis of the adsorbents. The

TDSA interfaceswith theGERSTELCIS4 Inlet thatservesas the

cryo-focusing trap for the desorption of the adsorbents.

Cryo-FocusingTrap

The GERSTEL CIS 4 inlet was used to re-focus the analytes

desorbed from theadsorbents.The injectionport linerof the inlet

contained twodifferentmaterials to facilitate the retentionof the

very volatile analytes in the test mix.We used liquid nitrogen to

cool the inlet liner to -150°C during the desorption of the adsor-

bent tubes.Wedesorbed the inletat350°C.Weusedastandard

inlet liner (available fromGERSTEL GC07540 10) and packed

the inlet with the following adsorbents:

●

CarbotrapC 20/40mesh: 10mm bed length

(25milligrams)

●

Glass Beads 60mesh: 6mm bed length (25milligrams)

This inlet configuration was determined after we performed

several experiments to optimize the chromatography of the gas

mix.

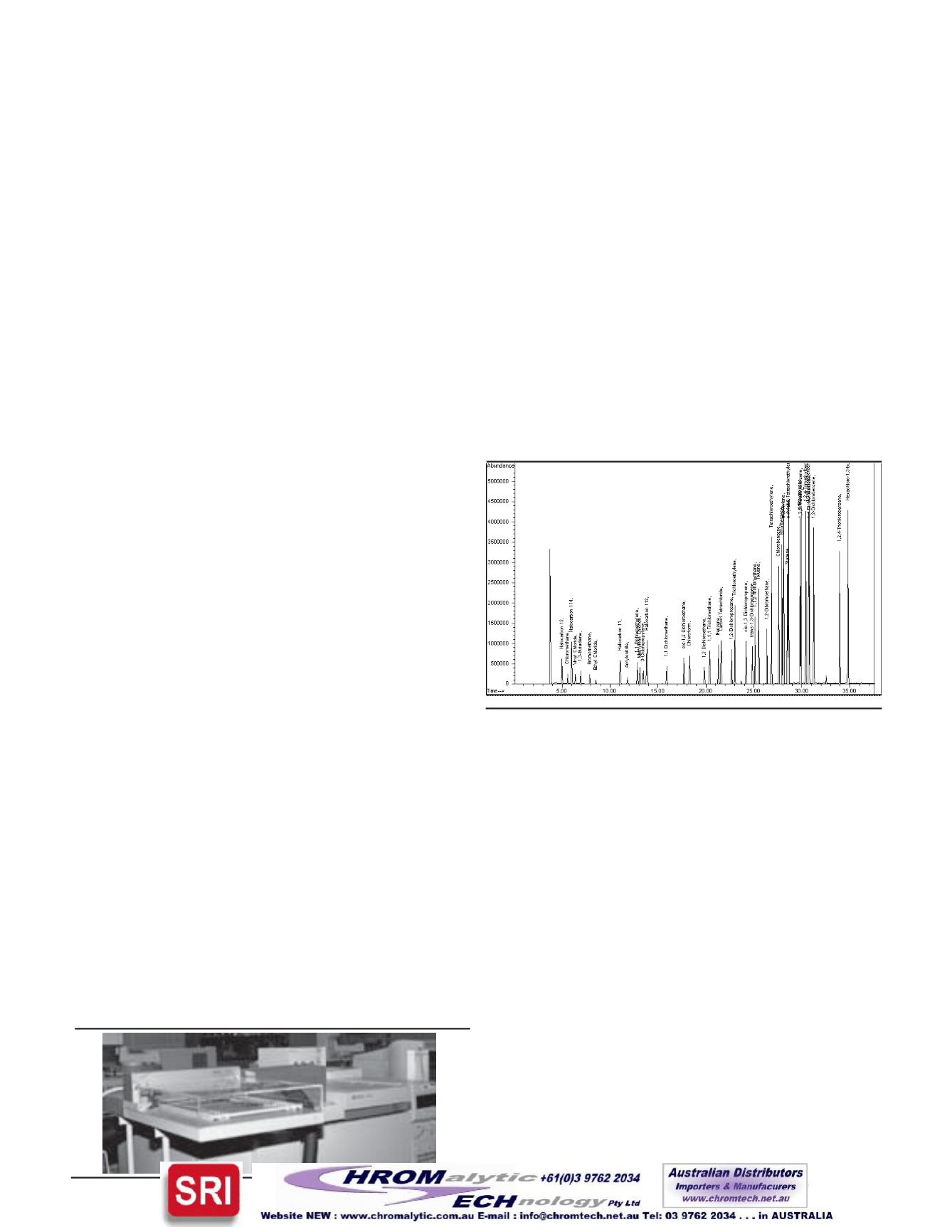

Figure2

shoesanexampleof thechromatographyachieved

with this set-up. (Notice the resolution of the first five analytes).

Figure2. TheResultsof theTestGas

Desorbed fromaCarbotrap300

GasChromatograph

Supelco used a Hewlett Packard 6890 GC with a 5973 mass

selective detector (Turbo Pump System) for the study. The

capillary column was a 60 meter x 0.25mm ID, 3.0µm film

SPB-1 column.

Other Equipment Used

●

Supelco’s prototype “Adsorbent Tube Injector System”

served as the device to transfer the gasmix onto the

adsorbent packed tubes.

●

DynathermModel 60 Six-TubeConditioner served as a

means to condition the packed adsorbent tubes. A

second unit served as away to control the flow rate

throughmultiple tubes simultaneously for the following

volume challenges: 1, 2, 5, 10, 20, and 100 liters.

●

Mettler Balancemodel AE100 served as away to

determine the actual bed-weights of each packed

adsorbent tube.

Table 3

shows the operating conditions for the equipment.

The largeCO

2

isconcentratedonto the refocusing trapduring theprocessof the

TDSA loading theadsorbent tube into thedesorber oven.

Figure1. GERSTELTDSACoupled

toaHP6890GC/5973MSD

CO

2