6

SettingUp theChallengeVolume

Thestudy lookedat sixdifferent challengevolumes:0.2,1,5,10,

20, and 100 Liters. The 0.2-Liter volume simulates the small

samplevolumeused inmost purgeand trapapplications. The1,

5 and 10 Liter volumes are typical sample volumes used in

thermal desorptionapplications (1,2). Thehigher volumesof 20,

and100-Literswerechosen for two reasons. First, itwill provide

users additional information if they need to use larger sample

volumes to increase detection limits by increasing their sample

size (volume).Second,youcanuse these largersamplevolumes

to differentiate one adsorbent from another. An example of this

wouldbeauser that needs toobtaina10 liter sampleof analyte

X. He/she can use the performance charts to compare the

adsorbents and choose the one that has good recoveries that

extend into20or100-Liter range.Bychoosing theadsorbent that

hascapabilitiesbeyond thedesiredsamplevolume, theusercan

safely assume they have chosen the appropriate adsorbent.

Table 4

shows the challenge volume parameters used in this

research.Thechallenge flow rateof0.05Liter/minwasconstant.

TheAnalysisMatrix

With twenty-four different adsorbents to test, six different vol-

umes for each adsorbent, and two desorptions of the same

adsorbent, this matrix adds up to over 288 analysis excluding

calibration and blank tubes. To minimize the effect of storage

timeon recovery,weconducted theanalysisandpreppingof the

tubes in fiveseries,asshown in

Figure4

.This reduced theeffect

of storage time, since theanalysisof the first tube to the last tube

spanned less than 5 hours.

Spiking theTest GasMixon theTubes

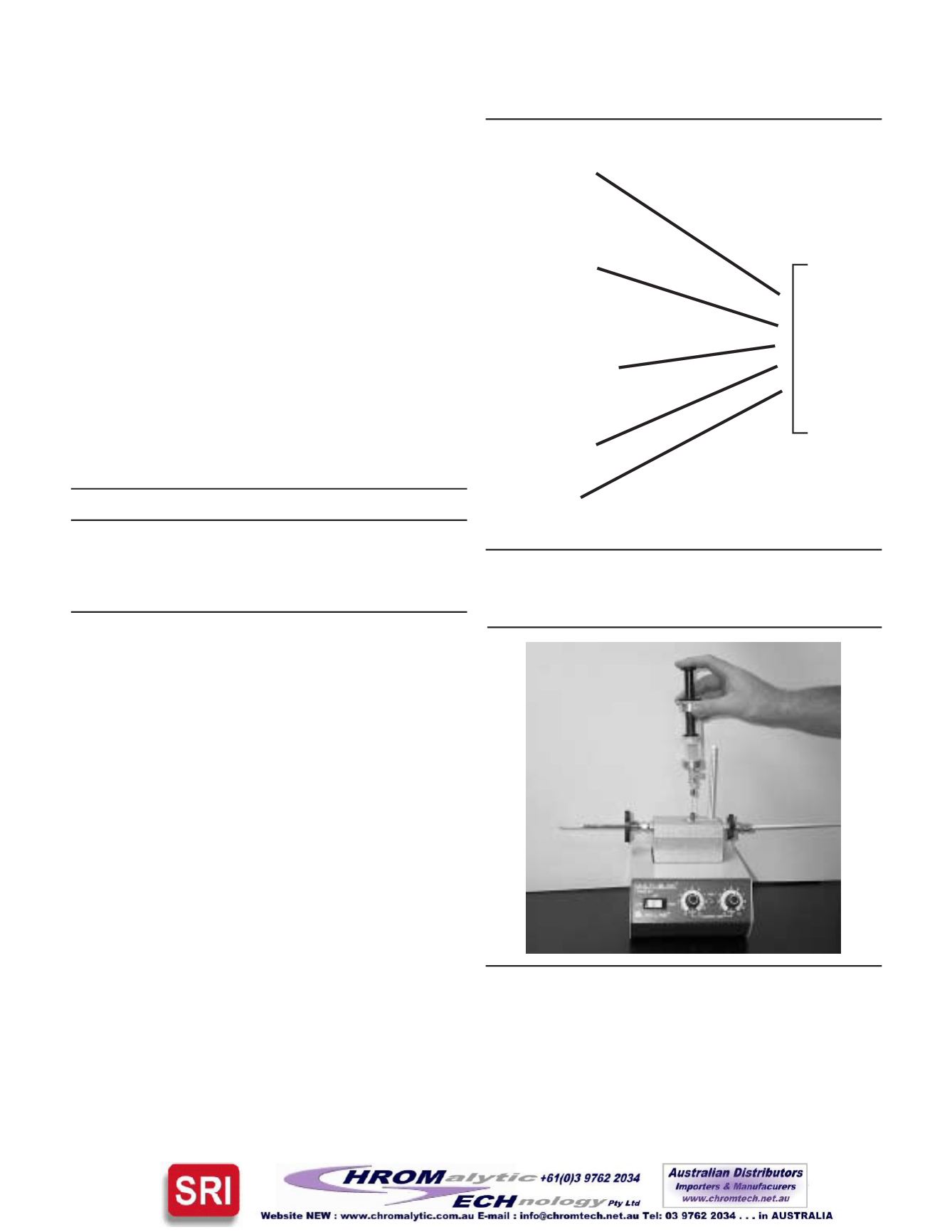

We introduced the 43 analyte gas mix onto each adsorbent

packed tube by using the technique of flash vaporization. This

wasconductedbyusingaprototypedevicedevelopedbySupelco

that is presently named the “Adsorbent Tube Injector System”

(See

Figure 5

). This device incorporates a Swagelok

®

union

fittedwithvespel/graphite ferrules that connected the inlet of the

tube toaglass injectionchamber fittedwithaseptaport.Ablock

of aluminum surrounds the glass injection chamber. This trans-

fers the heat of the Multi-Blok

®

Heater to the glassware. A

continuous flowof cleannitrogensweeps the injectionchamber.

Wemaintained the nitrogen flow rate for this research at 0.05L/

min using a constant flow controller.

A20mLsyringevolumeof theundiluted43-analytegasmixwas

injected into the septum port of the glassware while nitrogen

swept the test mix onto the inlet of the tube that was at ambient

temperature.After4minuteshadelapsed,we removed the tube.

The 0.2 Liter volume of nitrogen was enough to completely

sweep the test mix onto the adsorbent contained in the tube.

Series 1

GlassBeads

CarbopackF

CarbopackC

CarbopackY

CarbopackB

CarbopackX

Series 2

Carboxen-563

Carboxen-564

Carboxen-569

Carboxen-1000

CarbosieveS-III

Series 3

Coconut Charcoal

PetroleumCharcoal

SilicaGel Grade 15

PorapakN

Chromosorb 106

HayeSepD

Series 4

Carboxen-1001

Carboxen-1002

Carboxen-1003

Series 5

Tenax TA

TenaxGR

Carboxen-1016

Carboxen-1018

Challenge

Volumes

Set 1

0.2 Liter

Set 2

1 Liter

Set 3

5 Liter

Set 4

10 Liter

Set 5

20 Liter

Set 6

100 Liter

However, for the other five volumes studied, we physically

removed the tubes from theAdsorbent Tube Injector andplaced

them into one of the six-ports of aDynatherm tube conditioner.

Wechose theDynathermSix-tubeconditioner toprovide the rest

of the challenge volumes. The Six-tube conditioner has six

individualports that the flow ratecanbecontrolled independently

(See

Figure6

). Eachof the flowportswere set todeliver 0.05L/

min.

(Only the pneumatic section of this devicewas used, at all

times during the challenge volume the packed adsorbent tubes

remained at ambient lab temperatures

).

Table4. TheChallengeVolumeParameters

Challenge Volume Challenged FlowRate Challenge Time

(Liters)

(Liters/min)

(hours)

0.2L

0.05L/min

4min

1L

0.05L/min

20min

5L

0.05L/min

100min

(1 hr 40min)

10L

0.05L/min

200min

(3 hr 20min)

20L

0.05L/min

400min

(6 hr 40min)

100L

0.05L/min

2000min

(33 hr 20min)

Figure4. TheAnalysisMatrix

Figure5. SupelcoAdsorbent Tube Injector System

(spiking the test gas ontoa tube)