5

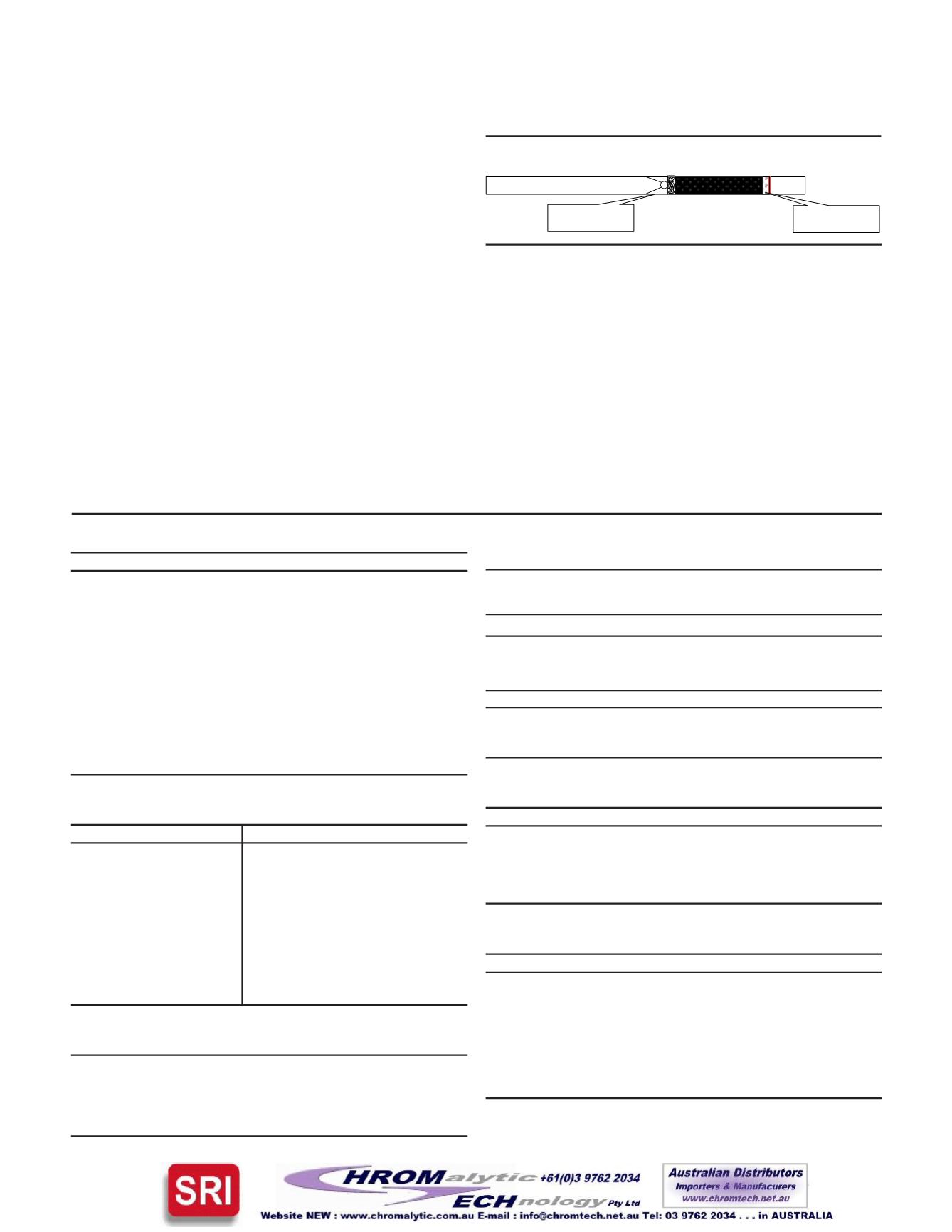

Flowdirectionduring theChallenge

FlowdirectionduringDesorption

Adsorbent occupieda

3.7cmbed-length

(0.5cc

3

volume)

Glass Frit

Inlet of the tube

SSClip

Glasswool plug

Figure3. Drawingof thePackedAdsorbent Tube

Depicting theBedLengthof EachAdsorbent

GERSTELTDSAParameters

GERSTELMASter Software

SampleMode

Standard

FlowMode

Solvent Venting

Transfer Temp

275°C

PurgeTime

1.00min

Initial Temp

25°C

Initial Time

1.00min

Delay Time

1.75min

1

st

RampRate

60°C/min

Final Temp *

Final Time *

2

nd

RampRate

0°C

Final Temp -NA-

Final Time -NA-

Online

-NA-

GERSTELCIS-4 Inlet Parameters

GERSTELMASter Software HPChemstation – Inlet Screen

CryoCooling ON

Mode

Solvent Vent

Equilib Time 0.2min

Inlet Pressure 26.7psi

Initial Temp -150°C Total Flow 14.0mL/min

(Set-point)

Initial Time

0.10min Vent Flow 20mL/min

1st RampRate 12°C/sec Vent Pressure 26.9psi

Final Temp 350°C Until

0.00min

Final Time 3.00min Purge flow 10.0mL/min

to split vent

2

nd

RampRate 0°C

@

0.01min

Final Temp -NA-

Final Time -NA-

GasSaver

Not used

Cryo-FocusingTrapCIS-4 Inlet Liner (Physical Data)

Inlet Liner Type Standard Liner with notch (GC07540 10)

Adsorbent CarbotrapC* 20/40mesh

andGlassBeads 60mesh

(* adsorbent is at the notch)

GlassWool Type UntreatedGlassWool

Each adsorbent was

desorbed for a total of 6

minutes. To achieve this,

the following conditions

were used:

*Final Temp *Final Time

180°C

3.5min

300°C

1.5min

330°C

1.0min

HP-6890GCParameters

OvenProgram

Ramp 1

Final

Initial Initial

Ramp 1 Hold

Final Hold

Temp Hold Rate 1 Temp Time Rate 2 Temp Time

35°C 8.00min 5°C/min 100°C 0min 15°C/min 230°C 8min

CapillaryColumn:

60meter x 0.25mm ID, 3.0µm filmSPB-1

(Available fromSupelco as a custom product).

ColumnParameters

Set-Point

Pressure

24.0psi

ColumnFlow

1.5mL/min

Avg. Velocity

31cm/sec

HP-5973MSD

ScanParameters

MSDTemperatureZones

LowMass

35amu MSQuad

150°C

HighMass

269amu MSSource

230°C

Threshold

200

MS Interface

230°C

EmVoltage

1576 Solvent Delay

0.00min

SamplingRate 2

3

Adsorbent Tube Injector System

Parameters

Block Temperature 65°C

Glassware

10mL InjectionGlasswarew/septa port

Transfer Gas

Nitrogen

Gas FlowRate

50mL/min

Transfer Time

4minutes

Transfer Volume

0.2 liters

SupplyPressure

50psig

Note: The actual adsorbent tube is not heated.

Sequenceof Events

Preparationof theAdsorbents

We packed each of the adsorbents into a 4mm ID x 6mmOD x

178mm frittedglass tube, basedona fixed volumeof 0.5cc.We

constructed a 0.5cc vessel by cutting a 3.7cm length of tubing

from a representative empty glass tube. We packed the adsor-

bent into the vessel and vibrated it to assure we obtained a

consistentvolumeof theadsorbent.We thenpoured thecontents

of the0.5ccvessel into theempty tube.We insertedasmall plug

of untreatedglasswool on topof theadsorbent bedalongwitha

small stainlesssteel clip toprovideadditional support tokeep the

adsorbent inplace.We thermallyconditionedeachof thepacked

adsorbent tubes for eight hours with a continuous flow of clean

nitrogen.

Figure 3

illustrates the packed adsorbent tube.

Table

1

lists the actual bedweights of each tube and the conditioning

temperatures used for each adsorbent. Further details on our

tubepackingprocedurecanbe found in theQuestions&Answers

section.

Table3. OperatingConditions