7

This freedup theAdsorbent Tube Injector to spike thenext tube

of the series by using the Dynatherm conditioner. After the

desiredchallengevolumehadelapsed, the tubeswere removed

and loaded into theTDSA thermaldesorber.Asequencewasset

toanalyze the tubesovernight.Weanalyzedeach tube indepen-

dently, and the results compared to a calibration curve.

CalibrationProcedures for theAnalytical System

It was not feasible to make syringe injections of liquid or gas

standards directly onto the column for two reasons. First, the

transfer lineof theGERSTELTDSAconnectsdirectly to the inlet

by a fitting that replaces the septum port. Second, the large

volumeof the testmixcouldnotbe injectedquantitatively. It isnot

practical to inject a20mL syringe volumeof the test gas directly

on toacapillarycolumnwithout altering the flowdynamicsof the

GC system.

Therefore, themodelwechose todetermine the recoverywas to

spike thesame20mLsyringevolumeof the testmixontoamulti-

bedCarbotrap300using thesame techniqueasperformed in the

previoussection.Thegasmixwassweptonto theCarbotrap300

tube with a total volume of 0.2 Liters using with the Adsorbent

Tube Injector. Thiswas enough volume to sweep theentiregas

mix onto the tube, but would not pose a challenge to the

combined adsorbents of thismulti-bed tube. With such a small

sample transfer volume (200mL), no loss of any analyte was

expected.Weassumed100% recovery from theCarbotrap300.

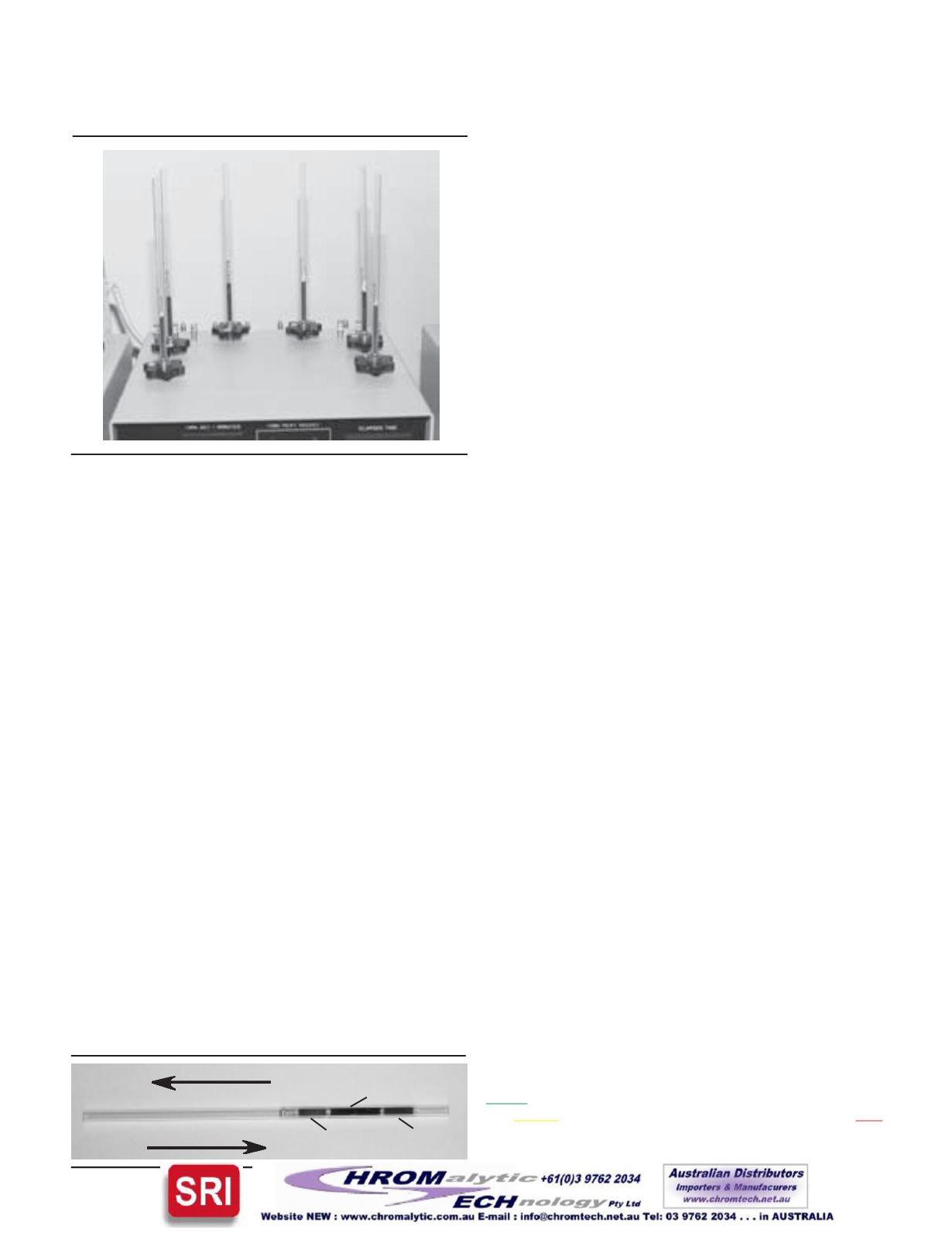

Figure 7

illustrates the flow direction we used to sample and

desorb the collected analytes.

Figure6. DynathermSix-TubeConditionerwith the

Tubes In-PlaceDuring theVolumeChallenge

Figure7. Pictureof theCarbotrap300Tube

Used for theCalibration

ChallengeFlowDirection

DesorptionFlowDirection

CarbosieveS-III

CarbopackB

CarbopackC

Constructing theCalibrationCurve

Six analytical runs made up the single-point curve for each

series. For each challenge volume (set) a Carbotrap 300 tube

was spikedwith the same 20mL syringe volume of the test mix

andanalyzedalongwith theadsorbentsof thatseries.Wecopied

the actual responses from the analysis directly into Microsoft

®

Excel. We set up a spreadsheet template to perform all the

recoverycalculations.Weaveraged theanalyte responses from

these six calibration runs and divided them by 100 to calculate

the average response factor for each analyte. We then consid-

ered the response factors as themodel of 100% percent recov-

ered.We createda separate calibration curve for each seriesof

adsorbents tested.Thisprocedure reduced theeffect of detector

drift over time, since thecompletionof the research tookseveral

months.

Calculating theRecoveryof theFirstDesorption

We divided the analyte response from each adsorbent by the

average response factor derived from the calibration curve

(above) and multiplied it by 100%. The result was the percent

recovered from the adsorbent.

We identified the analytes using the primary and secondary

quantitation ions of each analyte. The primary ion was used to

determine the area response of each analyte. (See

Table 2

for

the primary and secondary ions used in this research.)

Calculating theRecoveryof theSecondDesorption

Eachadsorbent tubewas re-desorbedat the same temperature

immediately following the primary desorption of each series of

adsorbents. Ifwe foundanyof theanalytes from the test, then the

recoverywasdetermined.This information is important because

if theanalyte(s)cannotbeefficiently released from theadsorbent

during the primary desorption then either the analyte is too

stronglyadsorbedor irreversiblyadsorbed.Thedifference is that

“toostronglyadsorbed

“means thatadsorbentretains theanalytes

to the point that they are not efficiently released from the

adsorbent duringdesorptionandaportionof it canbeobserved

in the second analysis.Where as, “

irreversible adsorption”

indi-

cates theanalytecannot be released from theadsorbent, and is

not observed in the second analysis.

Regardless of whether the adsorbent retains the analyte too

strongly or irreversibly adsorbs it; the user should choose a

different adsorbent for that analyte. In an effort to help users

choose the right adsorbent the performance charts include this

(*)symbol next to theanalytename ifweobservedmore than5%

of thatanalyte in thesecondanalysis.Thisallowsusers toquickly

observe which analytes they should not sample with certain

adsorbents.

Results:How toUse theCharts

To simplify the use of the reams of data generated by this

researchwe developed a simple scheme so users can visually

see the recovery basedon color rather than comparingmultiple

columns of numbers. We used the analogy of a traffic signal to

display the results.Theperformancechartsarecolor-coded,with

Green

indicating the recovery is greater than or equal to 80%.

The

Yellow

indicates the recovery isbetween21and79%.

Red

indicates the recovery is less than or equal to 20%. Using the

feature of “conditional formatting” in the Excel program, we

displayed the raw data by color instead of displaying the actual