Testing of Silcosteel

®

-CR treated coupons in

neutral, acidic, and basic chloride solutions,

according to ASTMG 61,

2

shows Silcosteel

®

-CR

treatment reduces corrosion rates by an

impressive 50x, compared to untreated 316L

stainless steel.

ImprovedPerformance inMarineor

AcidicEnvironments

Silcosteel

®

-CR treatment is effective in acidic or

salt corrosive environments, inwhich the user

demands extended service life for an existing

processwithout using high-priced alloys.

4000-hour salt spray testing (salt spray acceler-

atedweathering test ASTMB117) shows

Silcosteel

®

-CR treated stainless steel coupons

exhibit no surface corrosion, while untreated

coupons shows surface corrosion and accelerat-

ed corrosion at the coupon hole (Figure 4).

Neither coupons developed pitting over the test

period.

2

Figure 5, a comparison of lifetime costs in a

typical process system, shows Silcosteel

®

-CR

treatment can reduce the overall lifetime cost of

the system by hundreds of thousands of dollars.

While the initial cost of an unprotected stainless

steel system is lower than that of a comparable

Silcosteel

®

-CR system, the overall lifetime cost,

considering replacement cost due to corrosion, is

nearly double that of a Silcosteel

®

-CR treated

system. Conversely, high performance alloy sys-

tems offer superlative corrosion performance,

but the initial material cost can be up to six times

that of a comparable stainless steel system.

Silcosteel

®

-CR treatment has extended the life

of process systems in oil and gas production, oil

refining, petrochemical processing, aerospace

equipment, food and beverage processing, and

laboratory testing.

Silcosteel

®

-CR treated tubing and treated

Swagelok

®

or Parker fittings are available from

stock. Custom treatment is available for other fit-

tings, or for your process-specific components.

Summary

Test data show that Silcosteel

®

-CR treatment is

effective in extending the corrosion resistance

of stainless steel process systemswhile reduc-

ing overall systemmaintenance cost. Because

Silcosteel

®

-CR treatment can be applied to a

majority of existing process components,

process equipment life is extendedwithout sig-

nificant re-engineering.

To learnmore about how Silcosteel

®

-CR treat-

ment can improve the corrosion performance of

your process system, visit Restek Performance

Coatings on theweb at

or contact our technical service group at

814-353-1300 or 800-356-1688, ext. 4.

References

1. G. Koch;M. Brongers; N.Thompson;Y. Virmani; J. Payer;

Report# FHWA-RD-01-156,

CorrosionCost and Preventive

Strategies in theUnited States

; Office of Infrastructure

Research andDevelopment, Federal Highway Administration,

McLean, VA. 2001

2. M. Zamanzadeh; G. Bayer; G. Rhodes; D. Smith; M. Higgins;

Laboratory Corrosion Testing of a Chemical Vapor

Deposited Amorphous Silicon Coating

; Matco Associates,

Inc. Pittsburgh, PA; Restek Corporation, Bellefonte, PA.

2005

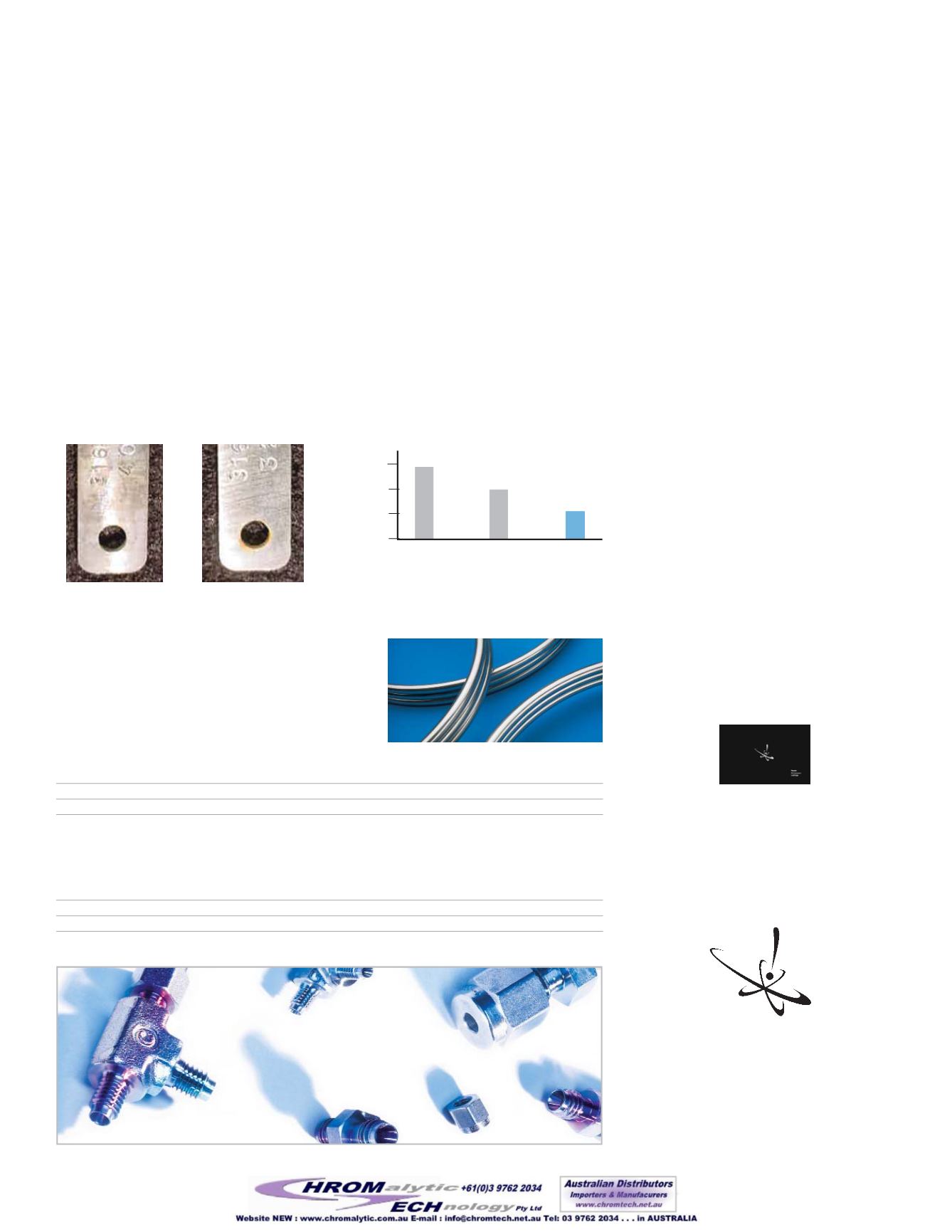

Figure4

Silcosteel®-CR treated316L stainless

steel coupons showno signof attackafter

4000-hour salt sprayexposure, perASTMB117.

Silcosteel®-CR treated

untreated

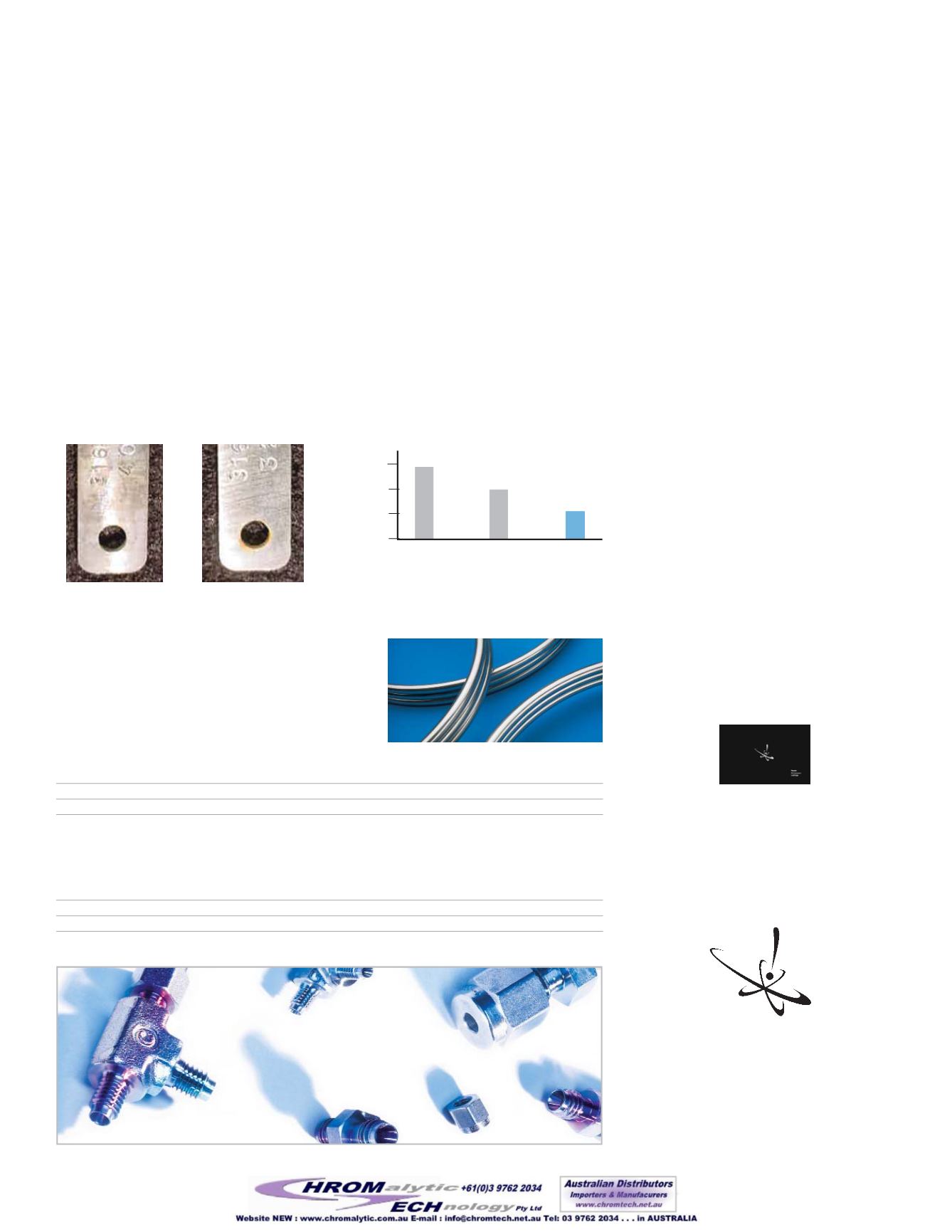

Figure5

Silcosteel®-CRdemonstrates

significant cost savings, compared tountreat-

ed stainless steel or alloys (USdollars).

Silcosteel

®

-CR-TreatedElectropolishedTubing

• Exceptional inertness.

• Improved reliability and reproducibility; longer

lifetime.

• Usewith treated fittings for themost inert sample

pathway available.

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-99 ft.

100-299 ft.

>300 ft.

0.085" *

1

/

8

"

22536

0.180" *

1

/

4

"

22537

CoiledSilcosteel

®

-CR -TreatedSeamless316LStainlessSteelTubing

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-199 ft.

200-399 ft.

>400 ft.

0.055" (1.40mm)

1

/

8

" (3.18mm)**

22896

0.180" (4.57mm)

1

/

4

" (6.35mm)**

22897

We offer awide variety of

Silcosteel®-CR-treated fittings

and custom treatment. For information and

ordering, call us or visit us online.

110Benner Circle • Bellefonte, PA 16823

800-356-1688•814-353-1300• fax: 814-353-1309

Restek

Performance

Coatings

Lit. Cat.#59090

© 2005 Restek Corporation.

free

literature

Learnmore about our precisely applied, highly

durable surface treatments: request our

brochure lit. cat.# 59493.

Restek trademarks:

Silcosteel, the RPC logo.

Other trademarks:

Swagelok (Swagelok Co.)

$600,000

$400,000

$200,000

0

untreated

stainless

steel

Silcosteel

®

-CR

*

1

/

8

" OD: 5 ft. to 100 ft. in one continuous coil;

1

/

4

" OD: 5 ft. to 300 ft. in one continuous coil. Longer lengthswill bemore than one coil.

**0.035" wall thickness

high

performance

alloy