Test Report

Study of 6NHClCorrosiononCommercial 316SS, HastelloyC-22 andTrueTubeVariants

DeterminationofTestData

The corrosion ratewas determined using theASTM equation established inASTMG31.

)

(

)

(

TDA

WK ate

CorrosionR

⋅ ⋅

⋅

=

Where:

K is a constant =3.45E6

W is theweight loss in grams

A is the exposed surfaceArea cm2

D is the densityg/cm2

T is the time in hours

The variance of each sample populationwas computed todetermine a confidence level for the results. The variance

was less than 1 for all samples except fused silica coating on commercial tubing. Variancewas calculated by the

equation:

n

x x

∑

−

)

(

where x is the samplemean and n the sample size.

Micrographic InspectionofTest Samples

In addition to the corrosion testingmicrographs of the sampleswhere taken at 500x after the exposure to6NHCl.

All themicrographs taken are of the surface after exposure to6NHCl.

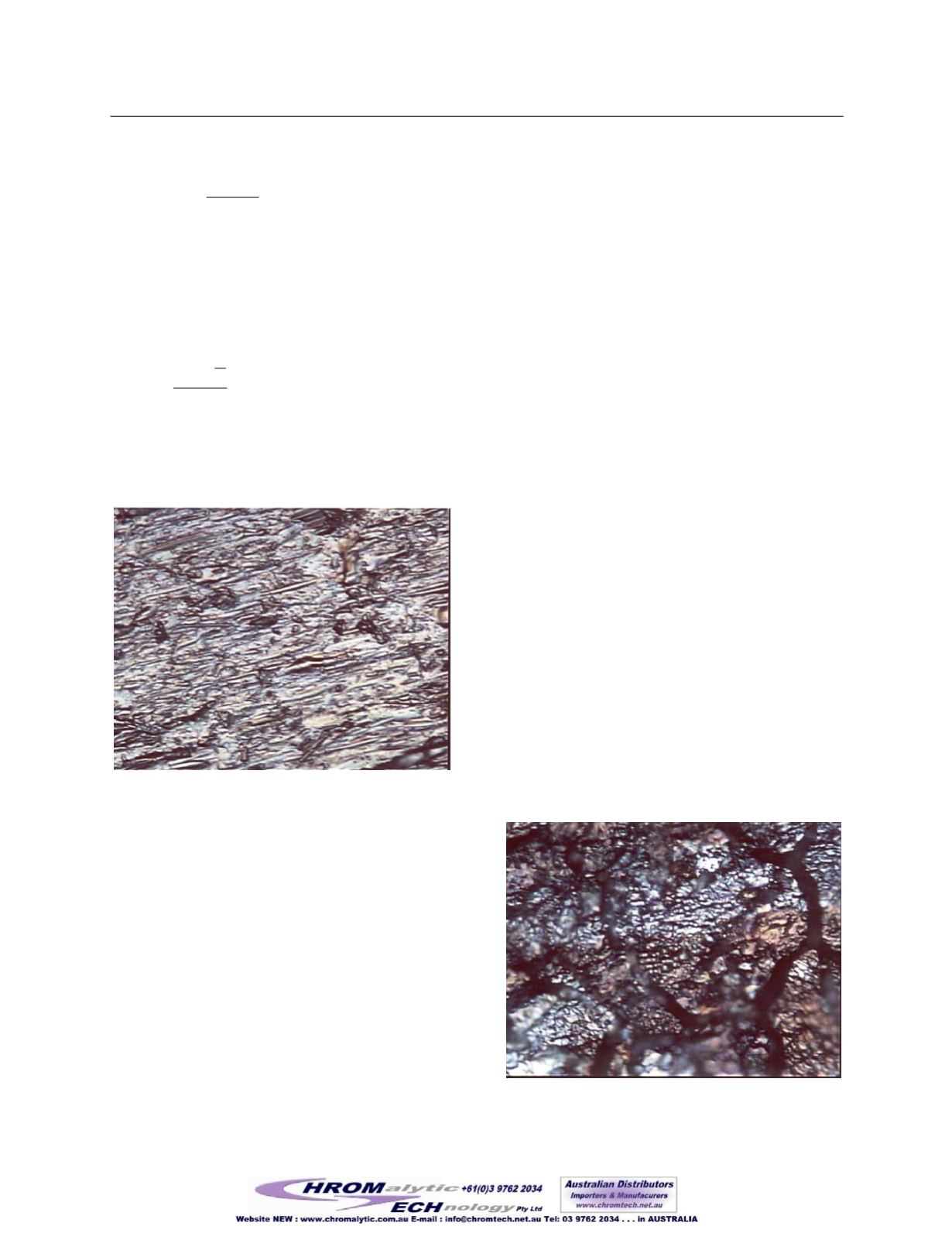

Figure 1 is themicrograph ofHastelloyC-22. It clearly

shows that the 6MHCl has barely touched the surface.

Figure 1:HastelloyC-22 500x

©2004O’BrienCorporation •QLT-TRTTCORR • 11AUG04

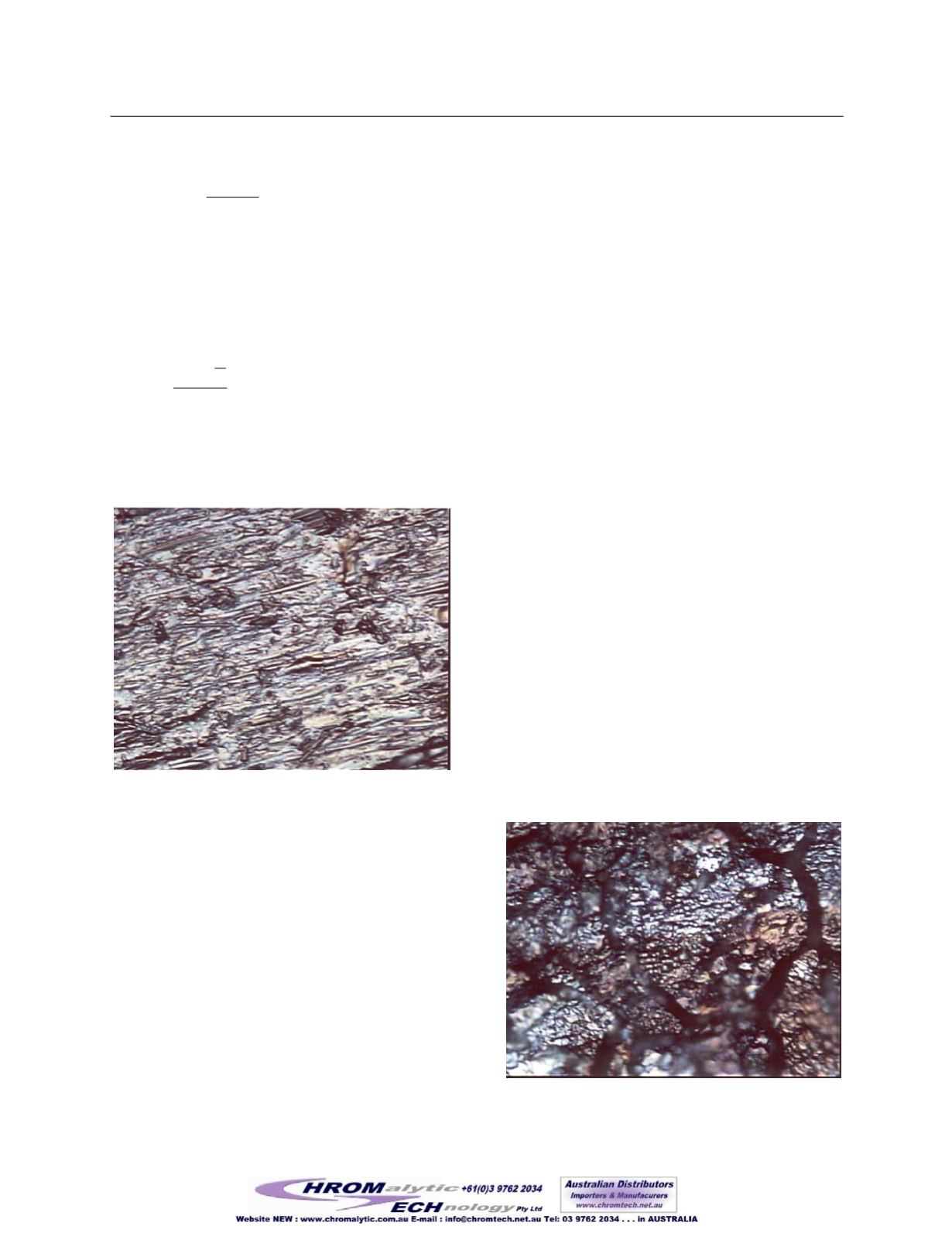

Figure 2 shows the surface of the commercial 316LSS

sample. There are several corrosionmechanisms occurring

here. The darken lines indicate grain boundaryattack.

There is alsogeneral corrosion due to the irregular surface

and some pitting. Comparing themicrographs of the

commercial 316LSS tubing and theTrueTubeEP tubing

illustrates the importance ofminimizing nucleation sites in

which pitting and general corrosion can occur. In the case

of the commercial tubing the nucleation sites are the peaks

and valley’s on the surface and process contamination. The

electropolishedTrueTubeEP processminimizes these

nucleation sites.

Figure 2:Commercial 316LSSTubing500x

Page 2 of 4

lit. cat.#RPC-cor2