Test Report

Study of 6NHClCorrosiononCommercial 316SS, HastelloyC-22 andTrueTubeVariants

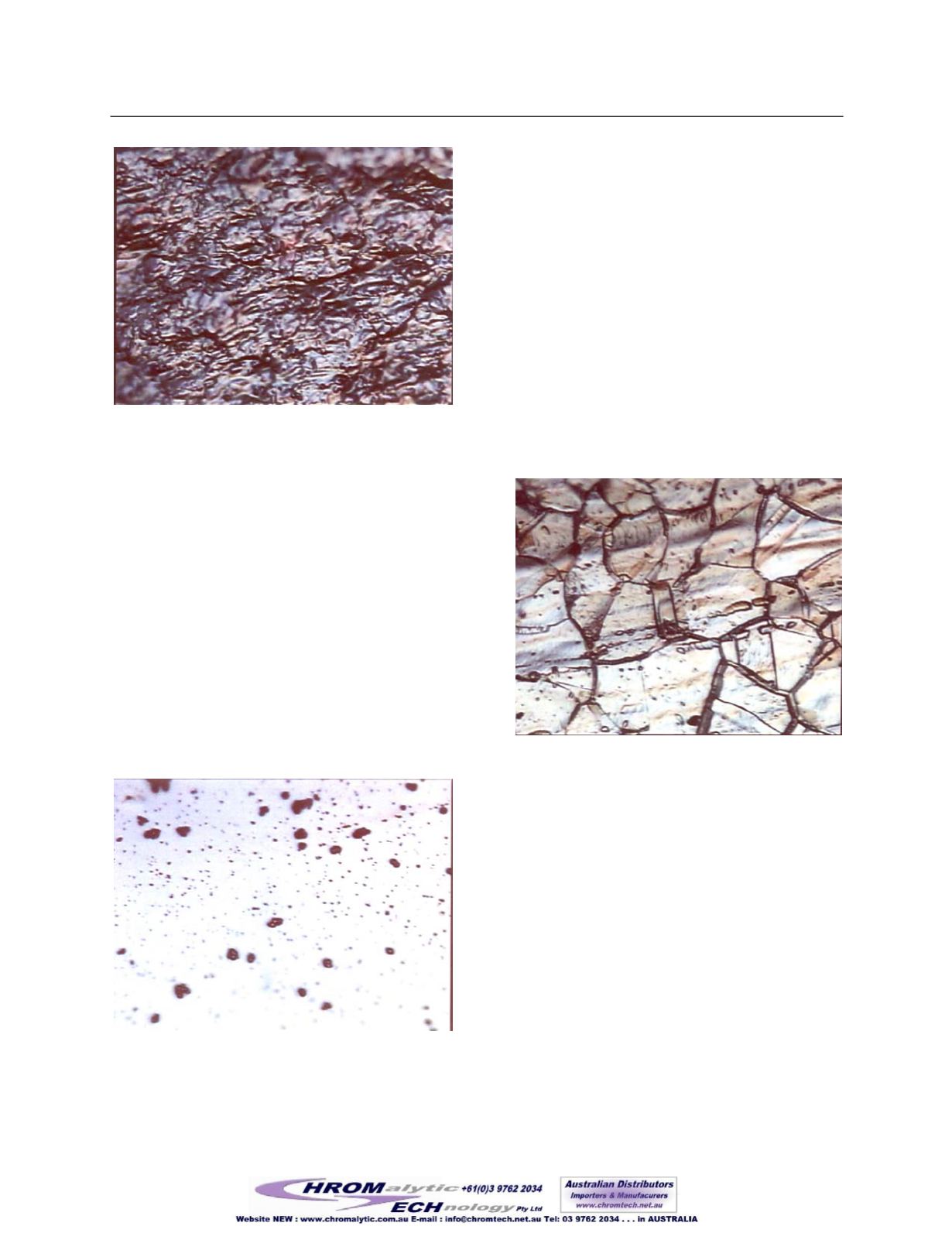

Figure 3 is the surface of commercial grade 316L tubing

with fused silica coating. Since the coating is transparent

the image shows themetallic surface and not the coating

surface. Because of the irregular surface roughness of the

tubing it is difficult todistinguish anyarea of preferential

attack. Several locationswhere inspectedwith no evidence

of total coating failure.

Figure 3:Commercial Grade SSwithFusedSilica

Coating500x

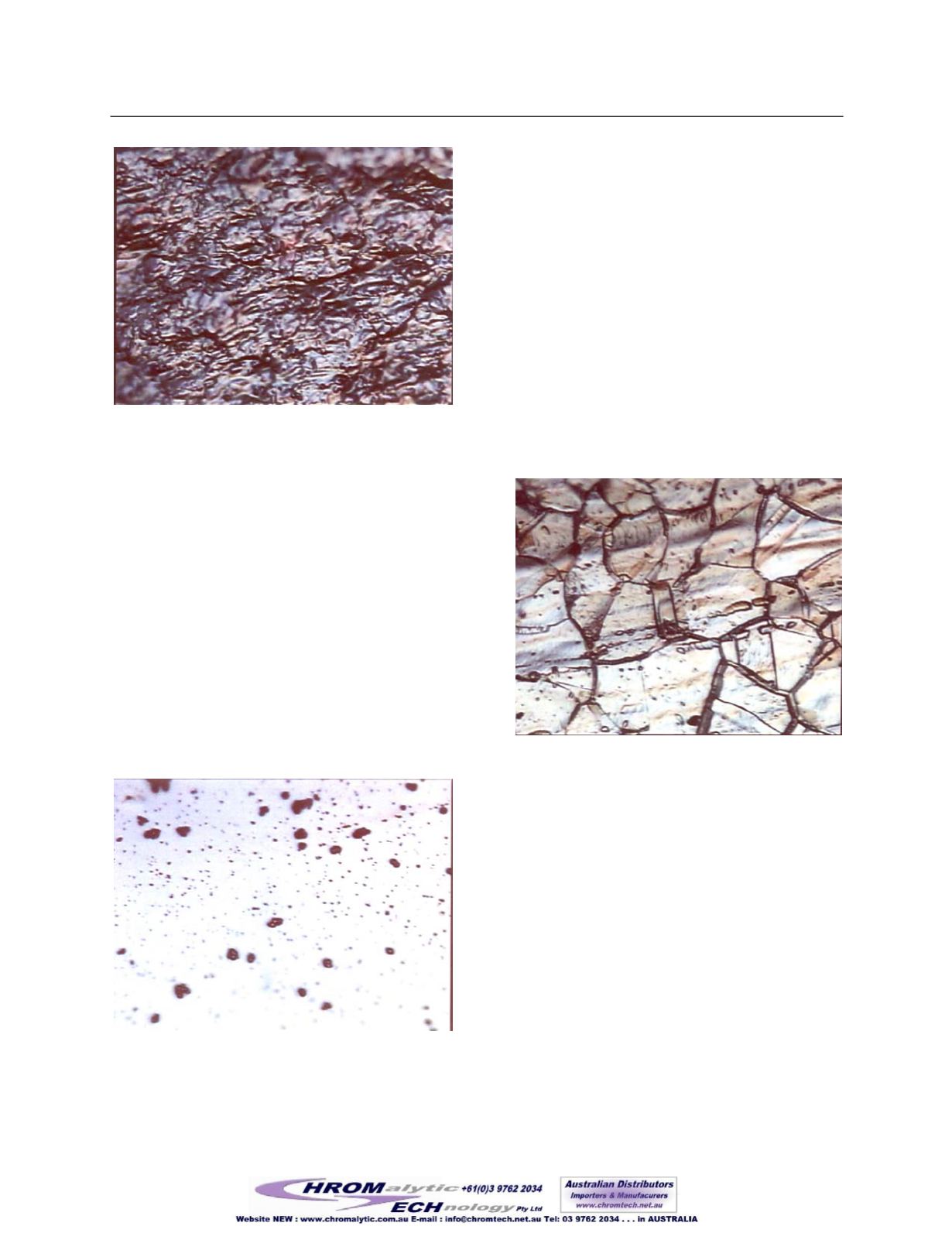

Figure 4 shows the surface of theElectropolishedTrueTube

EPTubing. Primarycorrosion is evident at the grain

boundarieswith some pitting internal to the grains.

Figure 4:ElectropolishedTrueTube EPTubing500x

Figure 5 is of theTrueTubeEPwith SiltekCoating

(TrueTubeEPS). Themicropitting of themetallic surface

is seen. This is the result of the electropolishing and

coating process not due to corrosion. The basemetal

surface appears untouched by theHCl. Comparing the

samples commercial grade fused silica (Figure 3) explains

the variance in corrosion rate. The discontinuities in the

coating for the fused silica coated commercial grade tubing

aremajor sources ofweight loss and directlyaffect the

corrosion rate.

©2004O’BrienCorporation •QLT-TRTTCORR • 11AUG04

Figure 5:TrueTubeEPS –ElectropolishedTubing

withSiltekCoating500x

Page 3 of 4

lit. cat.#RPC-cor2