After the tubingwas stabilizedwith 1ppm of

moisture, dry-down propertiesweremeasured.

Moisture dry-down curves for the three tubing

treatments show treated electropolished tubing

achieved dry-down in 35minutes, electropol-

ished tubing required 65minutes, and standard

tubing required 175minutes (Figure 2).Table 1

compares time to various dry-down levels for

tubing saturatedwith 10ppm of moisture.

In addition to rapidwet-up and dry-down, the

other key advantage of Restek treatment for

316L stainless steel is a dramatic improvement

in corrosion resistance.The amorphous silicon

layer is insoluble inmany of the acidic environ-

ments encountered in the semiconductor indus-

try. Figures 3, 4, and 5 briefly summarize the

results of corrosion testing by ASTMmethods.

Comparisons between treated and untreated

test samples illustrate the improvements in

corrosion resistance offered by Silcosteel

®

-CR

treatment. Formore information about

corrosion resistance, request information

packet 59048., or visit our website.

Whenmoisture considerations and corrosion

concerns arise in transfer of ultra-high purity

gas streams, Restek treated tubing and system

componentswill dramatically improve dry-down,

reduce contamination frommoisture carryover,

and extend periodicmaintenance cycles.

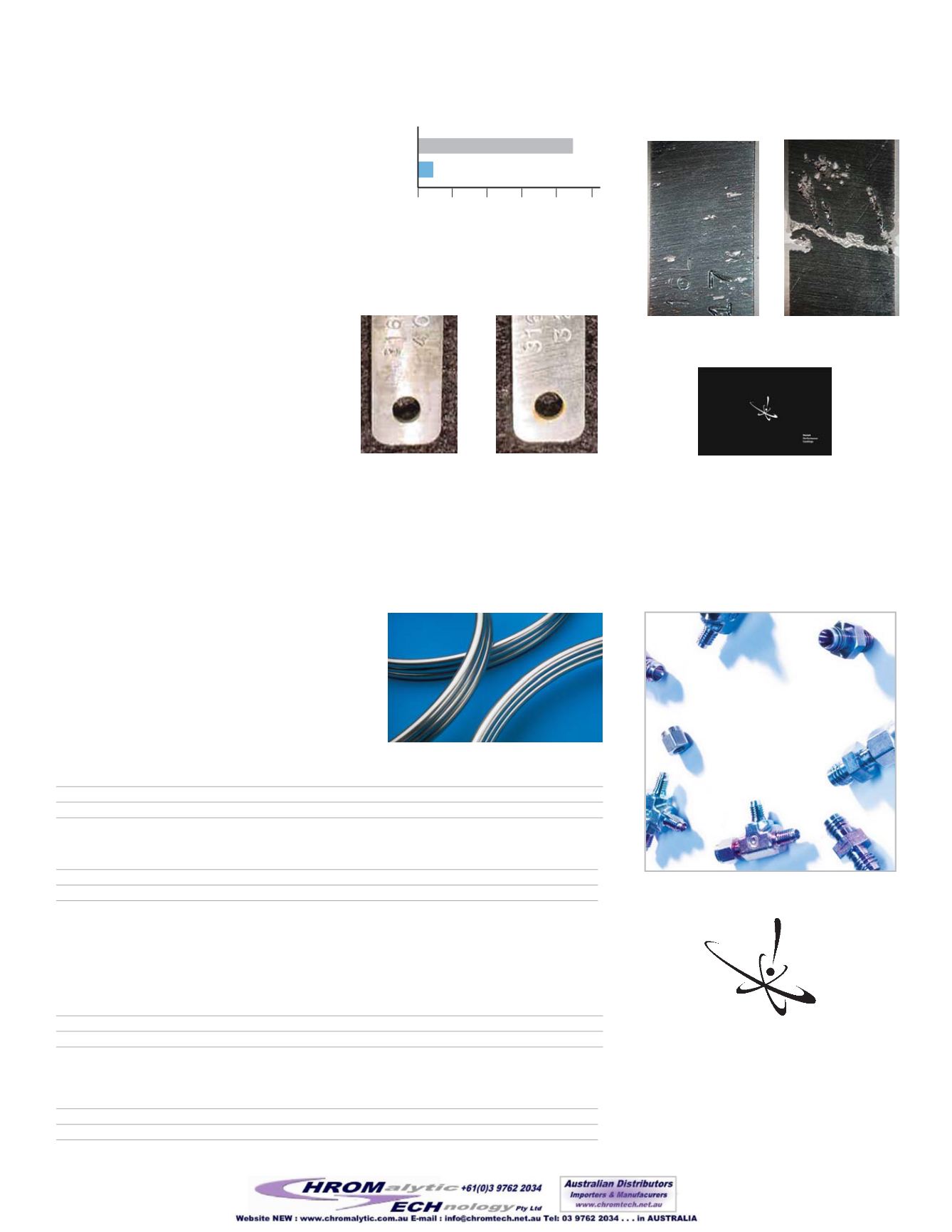

Figure4

Silcosteel®-CR treated316L stainless

steel coupons showno signof attackafter

4000-hour salt sprayexposure, perASTMB117.

Silcosteel®-CR treated

untreated

Siltek®-andSilcosteel

®

-CR-Treated

ElectropolishedTubing

• Exceptional inertness.

• Improved reliability and reproducibility; longer

lifetime.

• Usewith treated fittings for themost inert sample

pathway available.

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-199 ft.

200-399 ft.

>400 ft.

0.055" (1.40mm)

1

/

8

" (3.18mm)**

22896

0.180" (4.57mm)

1

/

4

" (6.35mm)**

22897

We offer awide variety of

treated fittings

and custom treatment.

For information and

ordering, call us or

visit us online.

110Benner Circle • Bellefonte, PA 16823

800-356-1688•814-353-1300• fax: 814-353-1309

Restek

Performance

Coatings

Lit. Cat.#580001

© 2005 Restek Corporation.

free

literature

Learnmore about our precisely applied, highly

durable surface treatments: request our

brochure lit. cat.# 59493.

Restek trademarks:

Silcosteel, Siltek, the RPC

logo. Other trademarks:

TrueTube (O'Brien Corp.)

*

1

/

8

" OD: 5 ft. to 100 ft. in one continuous coil;

1

/

4

" OD: 5 ft. to 300 ft. in one continuous coil. Longer lengthswill bemore than one coil.

**0.035" wall thickness

Figure3 In chlorideenvironments,

Silcosteel®-CR treated stainless steel

outperformsuntreatedmetal byanorder of

magnitude (ASTMG48,MethodB).

Figure5

Silcosteel®-CR treated316L stainless

steel coupons showno crevice corrosionand

only slight pitting corrosionafter 72-hour

exposure to ferric chloride; untreated coupons

exhibit severe crevice corrosion.

Silcosteel®-CR treated

untreated

0

50

100

150 200 250

Untreated 316 SS

Silcosteel

®

-CR

weight loss in grams per squaremeter

Reference

1.

Relative Response Time of True Tube

™

whenMeasuring

Moisture Content in a Sample Stream

Test Report, Haritec

Scientific & Engineering Support, Calgary, Alberta, Canada,

May 2004.

Reference courtesy of O'Brien Corporation, available on

request fromRestek.

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-99 ft.

100-299 ft.

>300 ft.

0.085"

1

/

8

"

22538

0.180"

1

/

4

"

22539

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-99 ft.

100-299 ft.

>300 ft.

0.085"

1

/

8

"

22536

0.180"

1

/

4

"

22537

Siltek®-TreatedElectropolishedTubing

Silcosteel®-CR-TreatedElectropolishedTubing

CoiledSiltek®-andSilcosteel®-CR-TreatedSeamless316LGrade

StainlessSteelTubing

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-199 ft.

200-399 ft.

>400 ft.

0.055" (1.40mm)

1

/

8

" (3.18mm)**

22508

0.180" (4.57mm)

1

/

4

" (6.35mm)**

22509

Siltek®-Treated316LTubing

Silcosteel®-CRTreated316LTubing