Silcosteel

®

-CR is a propri-

etary (patent pending),

multilayer silicon, chemical

vapor-deposited (CVD)

coating, specifically designed to improve corro-

sion resistance of steel, stainless steel, alloys,

glass, and ceramics.The unique non line-of-sight

CVD process produces a flexible amorphous sili-

con layer that diffuses into themetal lattice.The

layer will conform to themost intricate surface

whilemaintaining high dimensional tolerances.

Silcosteel

®

-CRwill deformwith tubing surfaces,

allowing leak-free seals or radius bends.

Independent LaboratoryTesting

Corrosion testing of Silcosteel

®

-CR treated 316L

stainless steel and untreated 316L steel accord-

ing to ASTMG 48, Method B

2

(72-hour ferric

chloride pitting and crevice corrosion testing),

shows corrosion of the treated stainless steel is

reduced by an order of magnitude, asmeasured

byweight loss (Figures 2 and 3).

ImproveCorrosionResistanceof

Stainless Steel Tenfold, orMore

Economical protection

against corrosion

Silcosteel

®

-CR treatment extends the lifetimes

of steel and steel alloy systems, while

maintaining high dimensional tolerances, high

temperature capability, and leak-free conditions,

making it an ideal treatment for:

•process tubing, fittings, valves, and reactors

•gas transfer and delivery systems

•nozzles

•stack gasmonitors

•analytical testing equipment

Silcosteel

®

-CR is highly effective protection for

equipment exposed to:

•hydrochloric, nitric, or sulfuric acid

•marine environments

ApplicationsNote

110Benner Circle • Bellefonte, PA 16823

800-356-1688•814-353-1300• fax: 814-353-1309

Restek

Performance

Coatings

Reducedowntimeandextend

system lifetimewithSilcosteel®-CR

treatment

Introduction

The annual cost of metallic corrosion in the

United States totals $276 billion

1

, ormore than

3% of theUS gross domestic product. Industry

is especially susceptible to high corrosion costs,

due to exposure of facilities and equipment to

both aggressive process chemicals and ambient

weather conditions.The annual direct cost of

corrosion toUS industry is $17.6 billion

1

.

Methods available to control industrial corrosion

are limited to corrosion-resistant alloys, barrier

coatings, cathodic protection, and corrosion

inhibitors.When properly applied, eachmethod

can be effective in slowing corrosion, but each

has limitations aswell. For example, some coat-

ings are inexpensive, but require rigorous

inspection and/or frequent reapplication.

Corrosion-resistant alloys can provide excep-

tional protection, but can be prohibitively expen-

sive. Some alloys require significant process

redesign, increase operating cost, or generate

hazardouswaste.

Silcosteel

®

-CR is a new class of performance

coating, offering an order of magnitude

improvement in corrosion resistance, or greater,

relative to existing processes. Silcosteel

®

-CR

maintains high dimensional tolerances, demon-

strates extreme heat capability, and exhibits

leak-tight system performance in steel, stainless

steel, and alloy systems.This study presents

laboratory corrosion test results and potential

cost savings of applying this alternative corro-

sion-resistant barrier coating technology.

Figure1

Corrosion costsUS industriesover

17.6billionper year (USdollars).

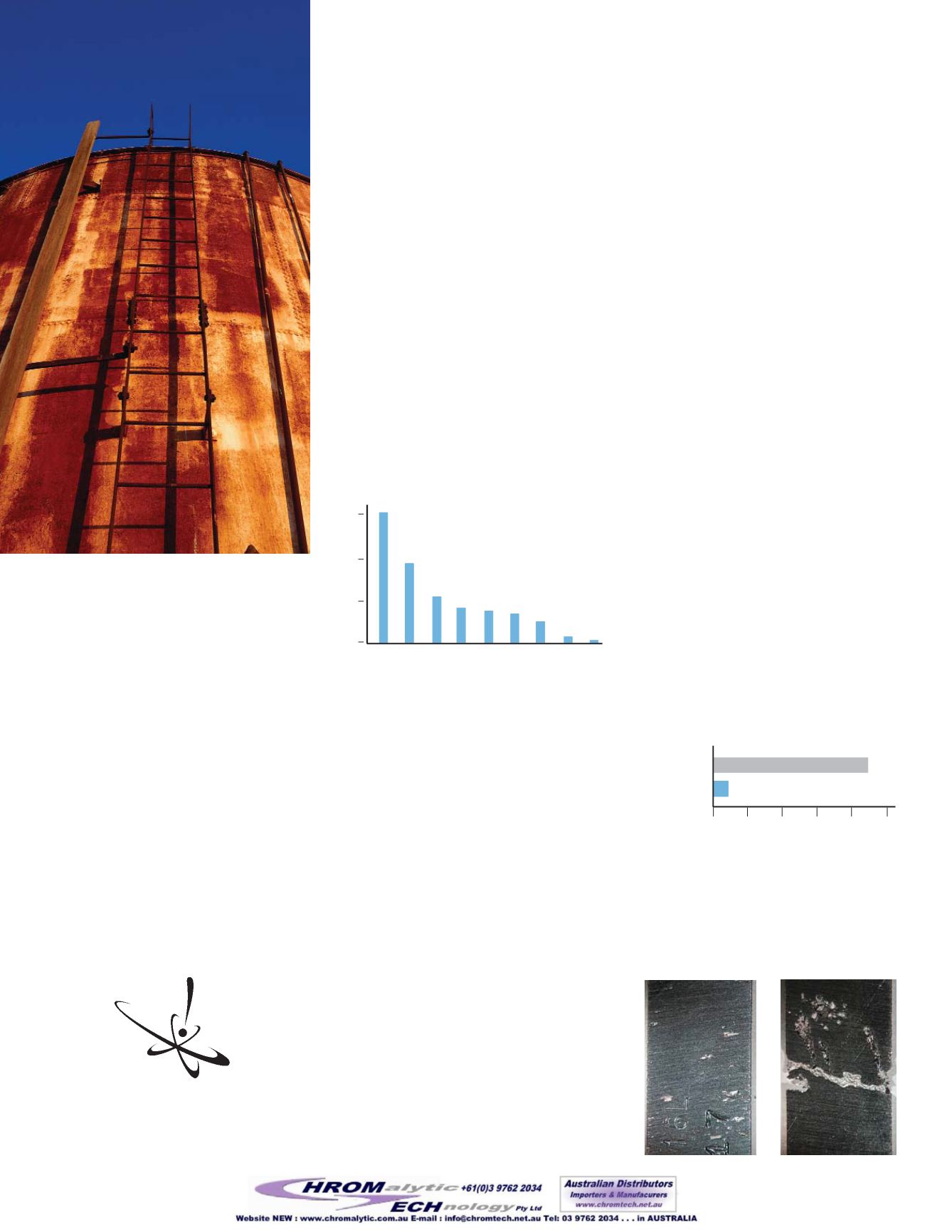

Figure2

Silcosteel®-CR treated stainless steel

outperformsuncoatedmetal byanorder of

magnitude (ASTMG48,MethodB).

Figure3

Silcosteel®-CR treated316L stainless

steel coupons showno crevice corrosionand

only slight pitting corrosion; untreated coupons

exhibit severe crevice corrosion.

Silcosteel®-CR treated

untreated

paper

refining

food

chemical

appliances

oil & gas

agricultural

mining

electronics

6

4

2

0

0

50

100

150 200 250

Untreated 316 SS

Silcosteel

®

-CR

weight loss in grams per squaremeter