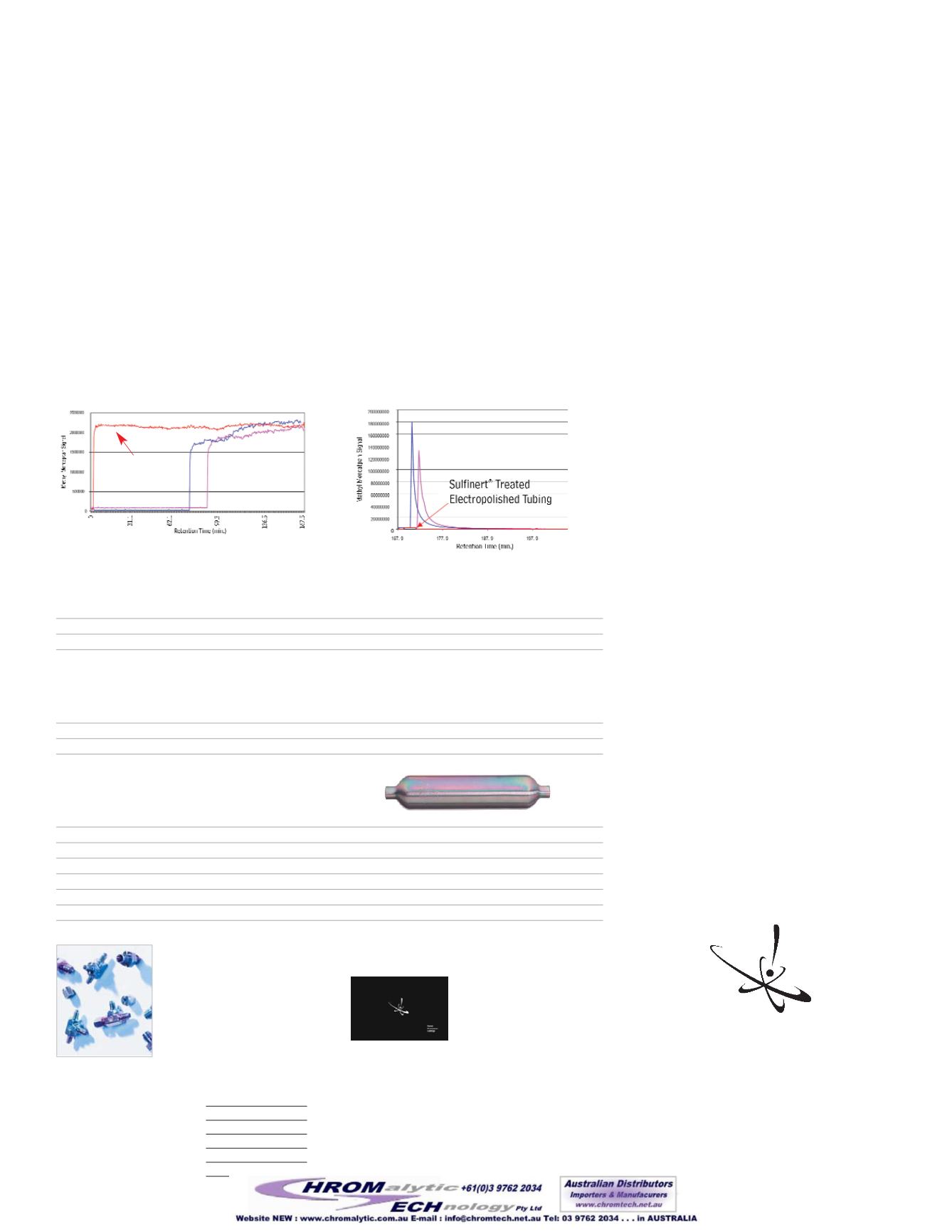

Figures 2 and 3 compare the transport proper-

ties of 100-foot (30.5-meter) lengths of the

three types of seamless 316L stainless steel

tubing,

1

/

8

" OD x 0.020" wall, using a gas stream

containing 0.500ppmvmethyl mercaptan in heli-

um as the test material.Testswere performed

at room temperature, using a gas flow rate of

40cc/minute.

Figure 2 demonstrates uptake of the sulfur com-

pound by the three surfaces.The performance

of the Sulfinert

®

treated, electropolished surface

is quite dramatic in comparison to that of

untreated electropolished tubing. Sulfinert

®

treated electropolished tubing did not adsorb

methyl mercaptan to anymeasurable extent,

delivering a representative samplewith no

delay.The untreated electropolished tubing, in

contrast, totally adsorbedmethyl mercaptan for

more than 75minutes, and the sulfur gas level

did not stabilize until approximately 130min-

utes. Conventional 316L seamless tubing totally

adsorbedmethyl mercaptan formore than 90

minutes, and the sulfur gas level did not stabi-

lize until approximately 140minutes.

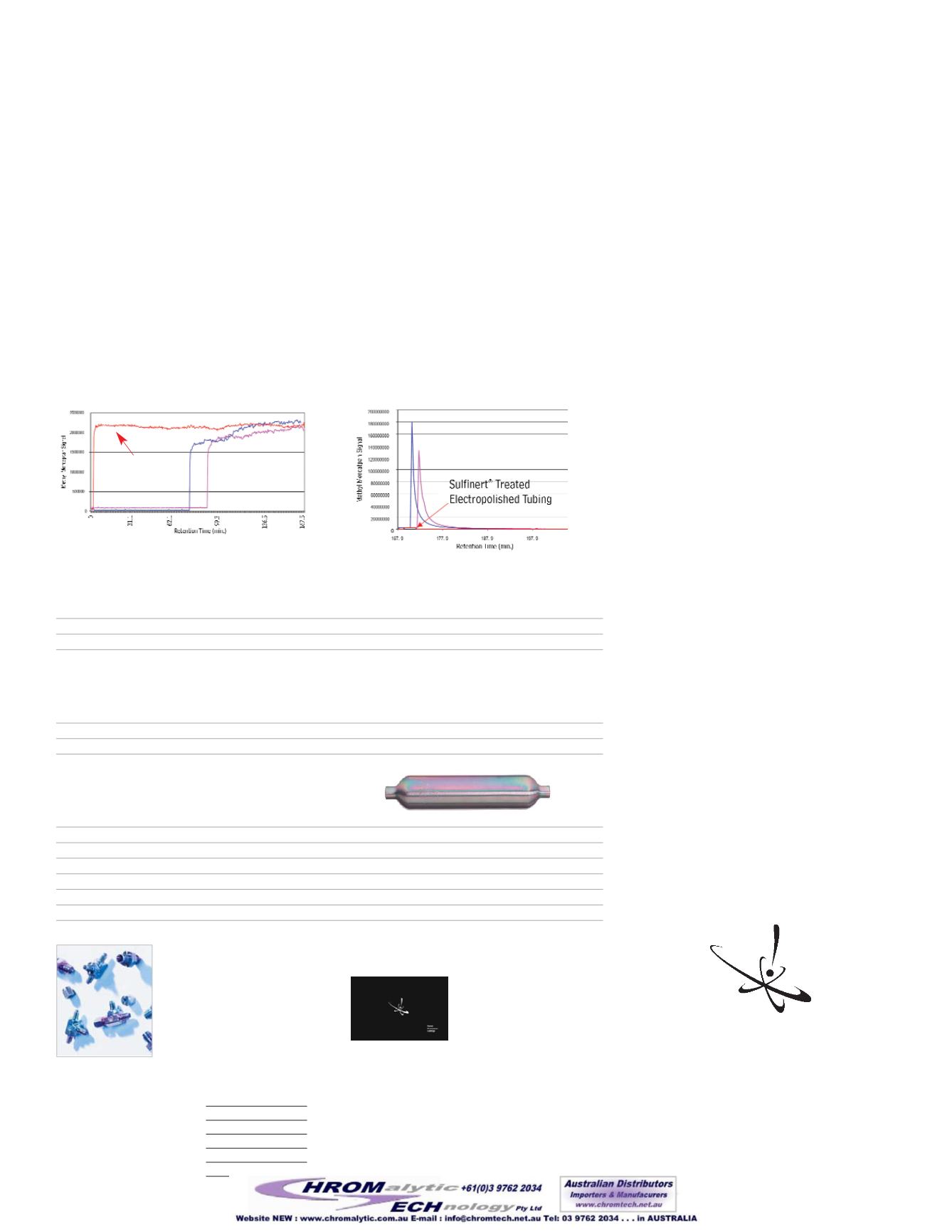

Closely correlated to the adsorption of sulfur

compounds by system components is the subse-

Figure2

Sulfinert® treatedelectropolished

stainless steel tubing (red) doesnot adsorb

methylmercaptan (500ppbv).

Blue—untreatedelectropolished tubing,

violet—commercial grade tubing.

Figure3

Sulfurmemory isprolonged in raw

commercial grade stainless steel tubing (violet).

Red-Sulfinert® treatedelectropolished tubing;

blue-untreatedelectropolished tubing

(500ppbvmethylmercaptan inhelium).

quent release of the adsorbed compounds.

When adsorption of sulfur-containing com-

pounds is prolonged, desorption from the sur-

face also is slow.This “memory” of adsorbed

active compounds can cause long delays in

equilibrating a sample stream. Figure 3 demon-

strates thememory effects of the three types of

tubing used to transfer streams containing sul-

fur compounds.The Sulfinert

®

treated tubing

shows less retention of sulfur compounds by

several orders of magnitude, indicating very

high inertness.

Valueofan InertPathway

The value of surface treated sampling and

transfer equipment is twofold: more accurate

results and faster cycle times. Improved accura-

cy and reliability of data for sulfur, achieved using

Sulfinert

®

treated transfer and sampling equip-

ment, mean downstream processes can bemore

precisely controlled, with associated cost sav-

ings. Shorter cycles translate directly intomore

samples collected and analyzed in a given period

of time.Typical savings can be calculated by look-

ing at the average per-hour cost of operating a

process that relies on accurate quantification of

sulfur compounds.

1

Examplemonetary values are

reported on the front of this note.

InSummary

We obtained accurate data, with no delay

between samples, by using Sulfinert

®

treated

electropolished tubing in the sampling-storage-

transport system. In contrast, we obtained sig-

nificantly less accurate data, evenwith delays of

more than two hours between samples, by using

untreated tubing. Analysts chargedwithmoni-

toring sulfur levels in process streams can sig-

nificantly improve profitability by using

Sulfinert

®

treated system components and

Sulfinert

®

treated electropolished tubing

transport lines.

Reference

1.

Application of TrueTube

™

in Analytical Measurement

Cardinal UHPAugust 2004

Available at

or by contacting us at

800-356-1688, ext. 4. Request lit. cat.# 59088.

Acknowledgement

The authors thank the staff of the Shell Research and

Technology Centre, Amsterdam, for data used in evaluating

sulfur gas uptake andmemory effects of tubing substrates.

Sulfinert

®

-TreatedElectropolishedTubing

**0.035" wall thickness

1

/

8

" OD: 5 ft. to 100 ft. in one continuous coil;

1

/

4

" OD: 5 ft. to

300 ft. in one continuous coil. Longer lengthswill bemore than

one coil.

Note: (required length inmeters) x (3.2808)= length in feet.

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-99 ft.

100-299 ft.

>300 ft.

0.085"

1

/

8

"

22538

$25/ft.

$20/ft.

$16.80/ft.

$14/ft.

0.180"

1

/

4

"

22539

$25/ft.

$20/ft.

$16.80/ft.

$14/ft.

CoiledSulfinert

®

-TreatedSeamless316GradeStainlessSteelTubing

please

note

An extra charge is applied

for cutting Sulfinert

®

tubing,

calculated from the total

number of pieces produced

for each line item:

Price-per-foot

ID

OD

cat.#

5-24 ft.

25-199 ft.

200-399 ft.

>400 ft.

0.055" (1.40mm)

1

/

8

" (3.18mm)**

22508

$18.75/ft.

$15/ft.

$12.50/ft.

$10/ft.

0.180" (4.57mm)

1

/

4

" (6.35mm)**

22509

$18.75/ft.

$15/ft.

$12.50/ft.

$10/ft.

Sulfinert

®

-TreatedSampleCylinders

D.O.T. rated to 1800psi at room temperature.

Size

qty.

cat.#

price

75cc

ea.

24130

$200

150cc

ea.

24131

$225

300cc

ea.

24132

$230

500cc

ea.

24133

$255

1000cc

ea.

24134

$425

2250cc

ea.

21394

$820

# of

Added

Pieces

Charge

5 to 15

16 to 30

31 to 75

76 to 99

100 to 200

Restek offersmany

Sulfinert®-treat-

ed fittings,

valves, sample

loops.

Formore information

and ordering, call us

or visit us online.

110Benner Circle • Bellefonte, PA 16823

800-356-1688•814-353-1300• fax: 814-353-1309

Restek

Performance

Coatings

Sulfinert

®

Treated

Electropolished

Tubing

Lit. Cat.#59082

© 2005 Restek Corporation.

free

literature

Learnmore about our

precisely applied, highly

durable surface treatments:

request our brochure lit.

cat.# 59493.

Restek trademarks:

Sulfinert, the RPC logo.

Other trademarks:

TrueTube (O'Brien Corp.)