environmental

Applications

note

RestekCorporation • (800) 356-1688 • (814)353-1300 •

#59111

environmental

MinimizingBreakdownof ChlorinatedPesticidesUsingSiltek

™

-Deactivated

GCAccessories

Gas chromatographic (GC) analysis of chlorinatedpesticides

presentsuniquechallenges toenvironmental laboratoriesbecause

these compounds often are at trace levels and susceptible to

decomposition. Some analyses, such as theUSEnvironmental

ProtectionAgency (EPA)Methods 8081 and608, have stringent

breakdownand reproducibilitycriteria.Breakdownoccurswhen

a compounddecomposes into related compounds, generally

because a thermal or chemical reactionhas occurred. Two

compoundsnotorious for exhibitingbreakdownareendrin,which

breaks down into endrin aldehyde and endrinketone, andDDT,

whichbreaks down intoDDE andDDD. The sourceof break-

down canbe aged samples and standards, theGC columnor,

most commonly, active sites in theGC injectionport. Routine

maintenanceof the injectionport, preventionof sample flash-

back, and thoroughdeactivationof the inlet liner andGC

columns are essential tominimize compoundbreakdown.

We chose apesticide analysis to compareSiltek

™

-deactivated

products against undeactivatedproducts.Toevaluate inlet liner

effects on endrin andDDTbreakdown, anHP5890GC equipped

with anRtx

®

-CLPesticides2 column and an electron capture

detector (ECD)was used.A50pg/µL standardof tetrachloro-

m

-

xylene, endrin, 4,4'-DDT,methoxychlor, anddecachlorobiphenyl

was injecteddirectlyonto the column andonto several different

liners.The areaof thebreakdownproductswas thenmeasured.

Heliumwas used as the carrier gas and the followingoven

programwas used: 120°C (hold1min.), to300°C at 9°C/min.

(hold10min.).The injectorwas set at 250°C and theECD at

300°C.

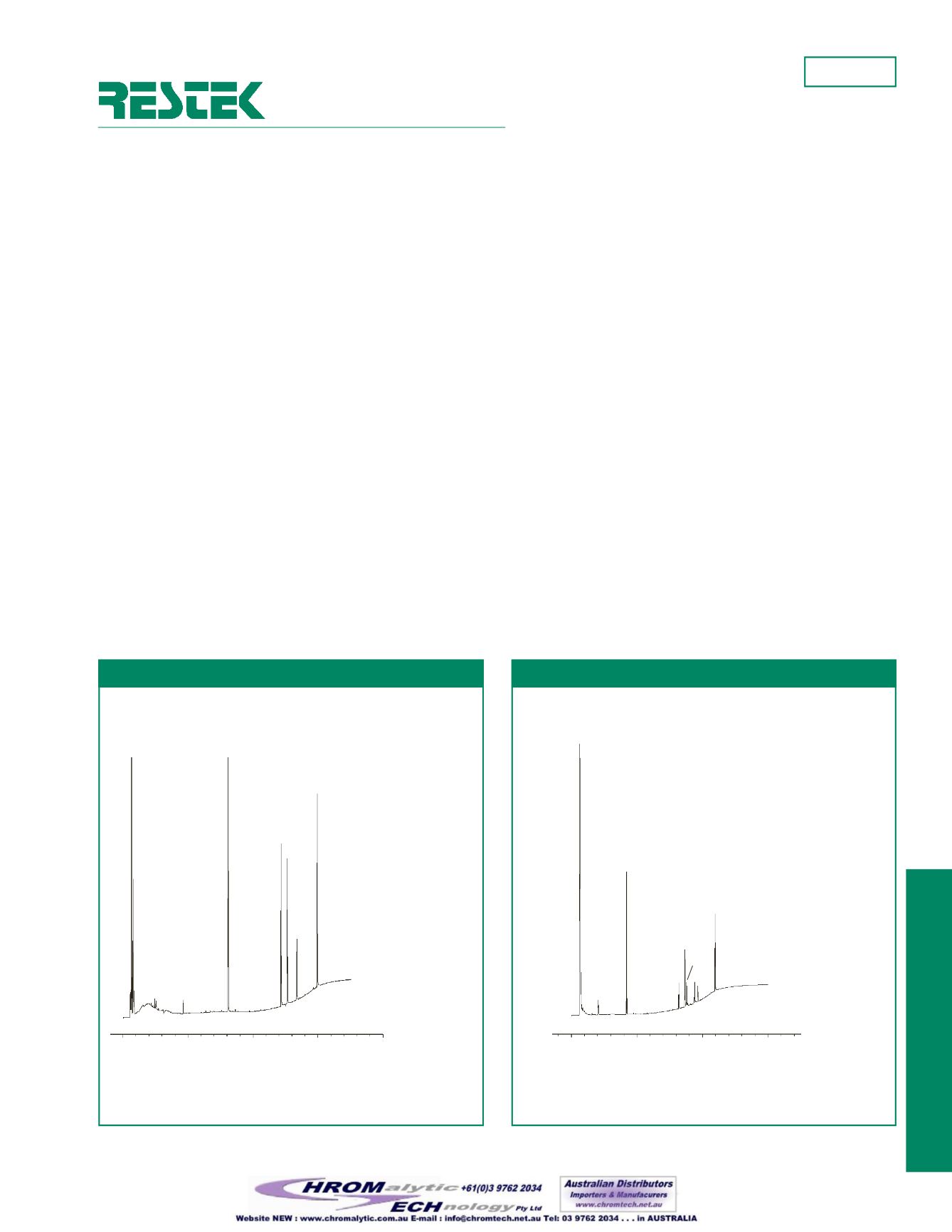

Tomeasure the column (i.e., “system”) breakdown, anon-

column injectionwasmade.This eliminated the effects of the

injectionport.Using this technique, endrinbreakdownwas 1%

andDDTbreakdownwas belowdetection limits (Figure1).

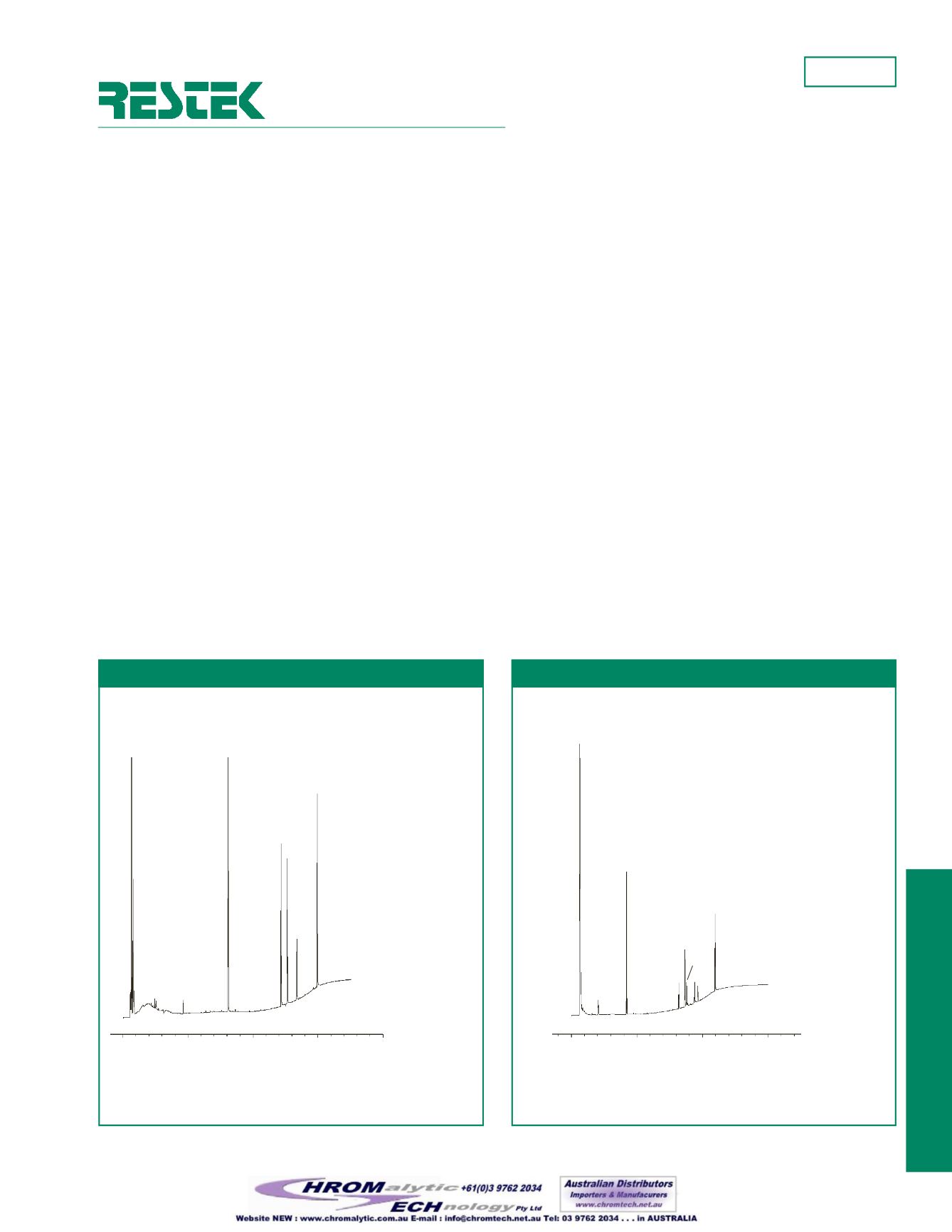

Asamplewas then introducedbydirect injection into an

untreatedglassUniliner

®

sleeve. The advantageof using a

Uniliner

®

sleeve

for adirect injection is that theGC column

forms apress-tight sealwith the liner, allowing thevaporized

sample todeposit onto the columnwithminimal injectionport

contact.Deactivation is critical for this techniquebecause a

direct injectionmaximizes contact of the samplevaporwith the

liner. The injection resulted in62% endrinbreakdownwithno

DDTbreakdown (Figure2).

1

2

3

4

5

Figure1

An on-column injection demonstrates system breakdown

of less than 1% for endrin andDDT using a

Siltek

™

-deactivated inlet liner.

0

10

Figure2

A chromatographic system that is inadequately

deactivatedwill cause poor linearity, poor reproducibility,

as demonstrated by 62% endrin breakdown.

30m, 0.53mm ID, 0.42µmRtx

®

-CLPesticides2 (cat.# 11340).

Inj.:

1µL of 50pg/µL standard.

Oven temp.:

120°C (hold 1min.)

to 300°C@ 9°C/min. (hold 10min.);

Inj. temp.:

250°C;

Det.:

ECD, 300°C;

Carrier gas:

helium.

1. 2,4,5,6-tetrachloro-

m

-xylene

2. endrin

3. 4,4'-DDT

4. endrin aldehyde

5. methoxychlor

6. endrinketone

7. decachlorobiphenyl

1

2

3

4

5

7

6

min. 0

10

20

30

20

30

40 min.

30m, 0.53mm ID, 0.42µmRtx

®

-CLPesticides2 (cat.# 11340).

Inj.:

1µLof 50pg/µL standard.

Oven temp.:

40°C (hold 1min.)

to 300°C@ 9°C/min. (hold 10min.);

Inj. temp.:

250°C;

Det.:

ECD, 300°C;

Carrier gas:

helium.

1. 2,4,5,6-tetrachloro-

m

-xylene

2. endrin

3. 4,4'-DDT

4. methoxychlor

5. decachlorobiphenyl