RestekCorporation • (800)356-1688 •

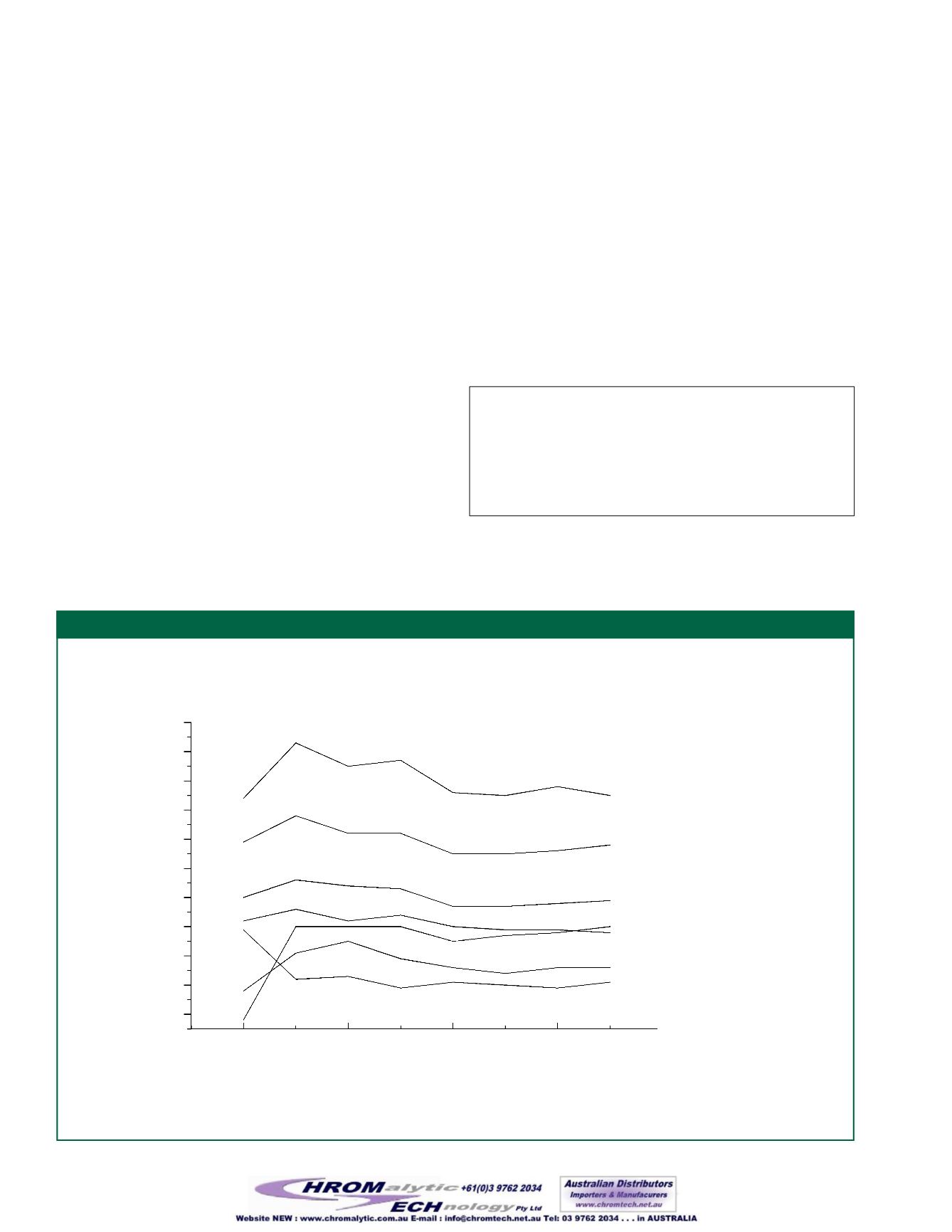

Figure2

Siltek

™

deactivation remains effective at an injection port temperature of 330°C for ten days.

Thermal Stability

To test the durabilityof theSiltek

®

liner deactivation, two

sources of stresswere investigated—high inlet temperatureover

aperiodof 10days and repeated exposure to aqueous injections

of low, thenhighpH.High inlet temperatures canpromote

degradationof the deactivation layer by causing it tobake or

bleedoff of the liner. In the first study, a baseline splitlessXTI

injectionwas performed, and response factors (relative toC14)

were calculated. The injectionportwas then set at 330°C

overnight and anotherXTI injectionwasmade. This processwas

continued for 10days.After 10days at 330°C, theSiltek

®

deactivation retained its integrity, achievingessentiallyunchanged

response factors, even for thecritical probes (Figure2).

Resistance toChemicalAttack

For the next durability study, aSiltek

®

-deactivated linerwas

repeatedly exposed to aqueousHCl injections, pH1.4.The

ability towithstand lowpH aqueous samples is importantwith

environmental applications that require acidificationof the

matrix.Very lowor veryhighpH samples can cause pinpoint

holes in the deactivation layer thatwill eventuallyundercut the

layer and strip it away. For this study, a baselineXTI injection

wasmade via direct injection and relative response factorswere

calculated. In the direct injectionmode, a leak-free connection is

formed in the liner,minimizing sample exposurewithin the

injectionport.Tenmicroliters of the pH1.4 samplewere

injected, followedby a direct injectionof theXTI testmixture.

This cycle continueduntil a total of 180µLwere injected (Figure

3).Keyprobes, such as 2,4-dinitrophenol (DNP), pentachlo-

rophenol (PCP),

N

-nitroso-di-

n

-propylamine (

n

-propylamine),

and1,2-hexanediol (diol) retained their responses up to at least

120µL injected.

The experimentwas repeatedwith an identical set-upusing

aqueousNH

4

OH injections, pH10.1 (Figure 4).Under these

demanding conditions, the response for theXTI compoundswas

consistent for 70 injections.As expected, the response of the

acidic compounds began todecreasewith repeated injections but

many compounds continued tohave excellent response formore

than120µL injections.

Siltek

®

deactivationoffers both inertness and resistance to

temperature andpH extremeswithin aGC system. It is available

as a deactivation for fused silica guard columns and inlet liners.

Formore informationonSiltek

™

—

thenext generationof deactivation,

please request our Siltek

™

Benefits

brochure (cat.# 59803).

30m, 0.25mm ID, 0.25µmXTI

®

-5 (cat.# 12223) with a Siltek

™

-deactivated splitless sleeve (cat.# 20798-214.1).

Oven temp.:

40°C (hold 2min.) to

190°C@ 6°C/min., to 330°C@ 30°C/min. (hold 10min.);

Inj. temp.:

330°C;

Det.:

330°C;

Carrier gas:

He.

1,2-hexanediol

N

-nitroso-di-

n

-propylamine

benzoic acid

2,4-dinitrophenol

4-nitrophenol

4-nitroaniline

pentachlorophenol

Day 1

Day 5

Day 7

Day 9

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

ResponseRelative toC14

#Days InjectionPort at 330°C