UsingFerruleswithSRI GCs

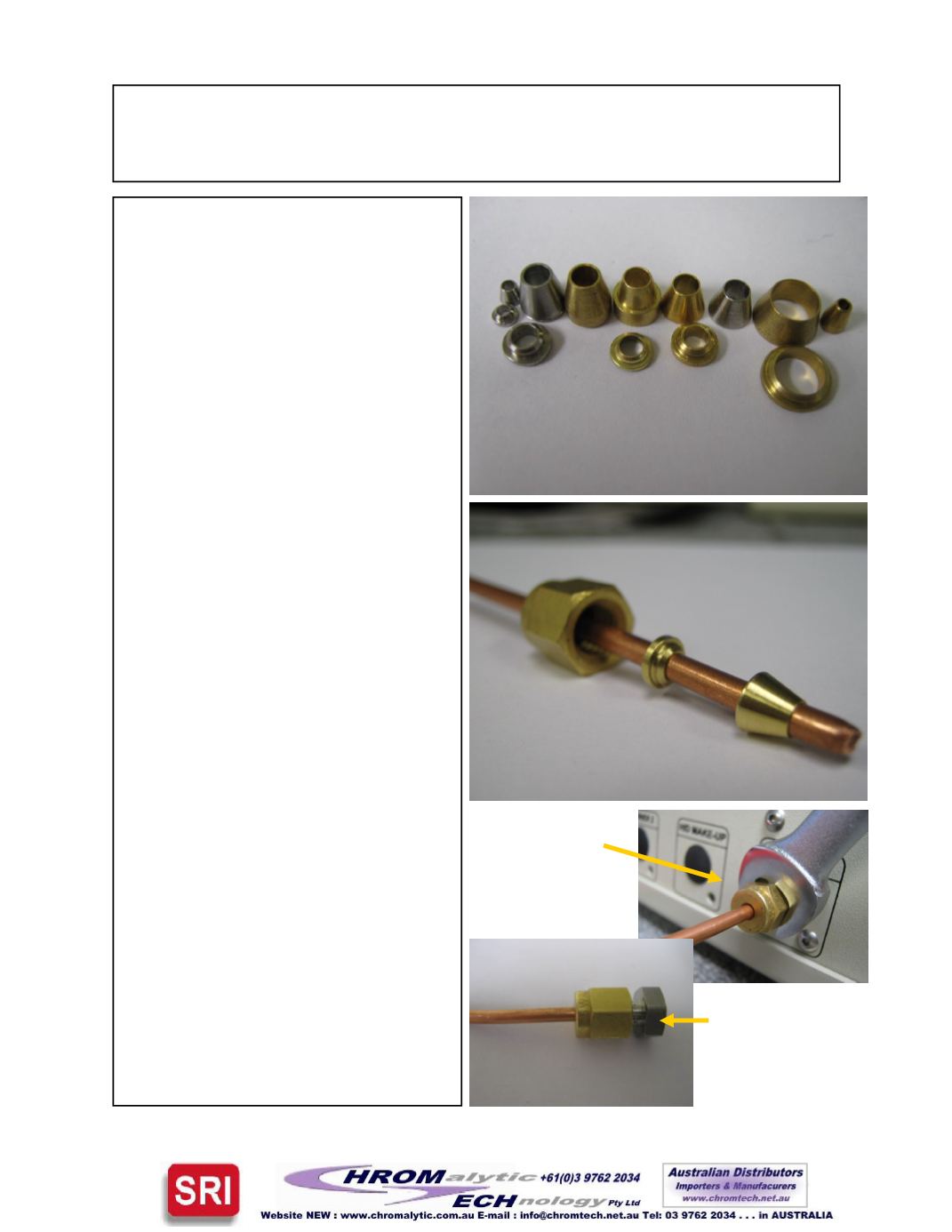

Therearemany different typesand

sizes of

brassand stainless steel fer-

rules

, but their basic use and installation

is the same. Brass ferrulesare softer

andmore reliablewhen connections are

made and remade several timeswhile

stainless steel is best under operating

temperatures exceeding 300degrees.

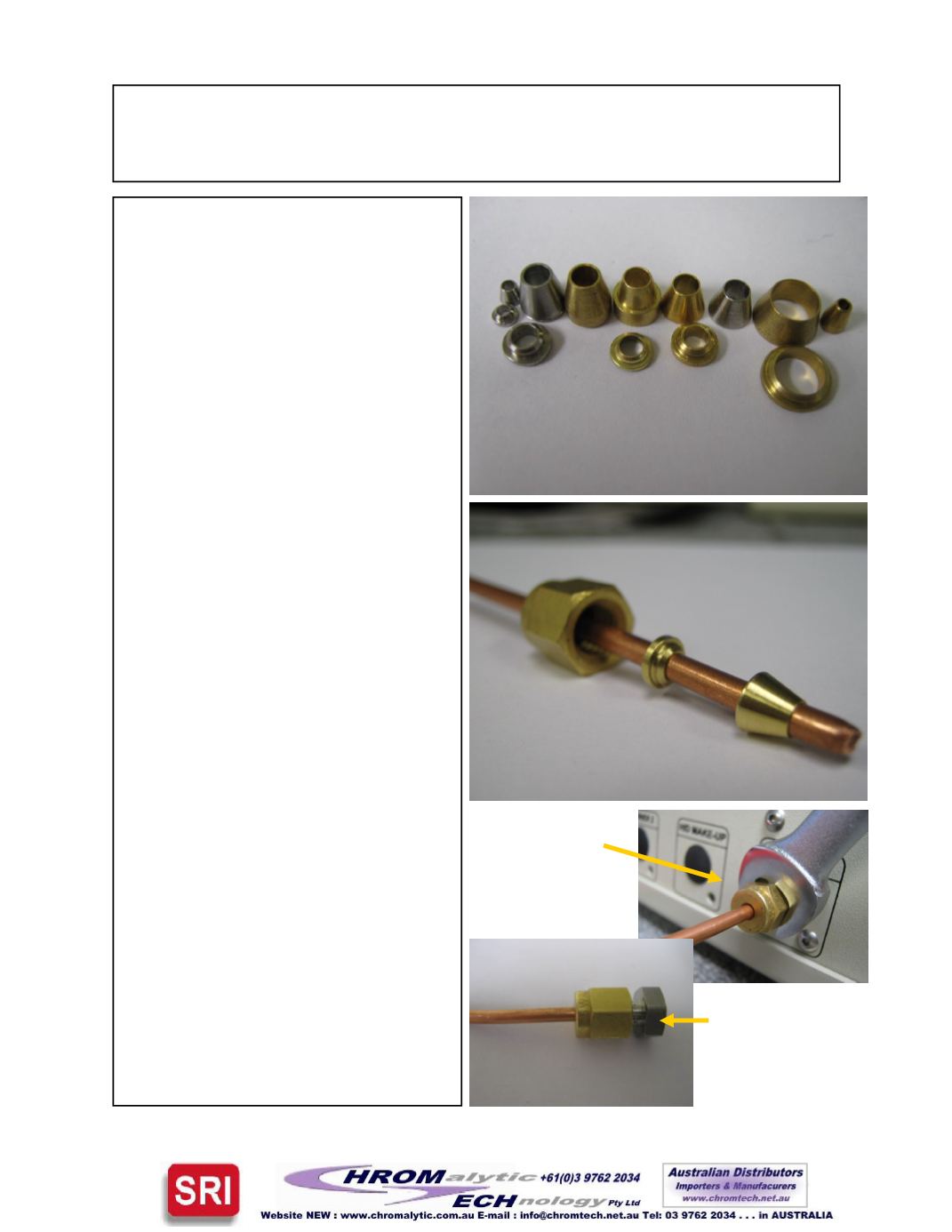

Wewill illustrate how to install a

two-

part ferrule

with 1/8” copper carrier gas

tubing anda 1/8” Swagelok brass nut

and 1/8” two-piece ferrule.

Slip thenut over the tubingwith the

threaded opening facing outwards.

Place the brassback ferruleonto the

tubingwith the narrowend facingout-

wards. Slip the brass front ferruleonto

the tubingalsowith the narrowend fac-

ingoutwards. The two ferrulesarede-

signed to fit together.

Thread thenut either straight onto a

male fitting, or, preferably onto a

stainless-steel cap first and tightenwith

a 7/16” wrench (twowrenches if you are

usinga cap). It’sa good idea touse a

newand undamaged stainlessmale fit-

ting the first time you tighten up the fer-

rule because thiswill ensure the ferrule

takes the correct shape. Brass fittings

are sometimes deformed frompast over-

tightening.

You should turn thewrench approxi-

mately one-half turn past finger tight in

order to get the proper tightness. If the

ferrule is too loose it will not producea

gas-tight seal, if it is too tight the ferrule

can be smashed or deformed and also

prevent a gas-tight seal.

Page 2

Okay . . .

….but this isbetter because

the stainless cap ismore

likely to form the ferrule to

the proper shape than a

possibly deformed brass

fitting