environmental

Applications

note

RestekCorporation • (800) 356-1688 • (814)353-1300 •

#59150

environmental

OptimizingMassachusettsVolatilePetroleumHydrocarbonGCAnalysis

TotalPetroleumHydrocarbon (TPH) analysisallows thecharacter-

izationofdozensof commerciallyavailablepetroleumproducts,

whichare themost prevalent environmental pollutants.The two

fractionsofTPH—volatilegasoline rangeorganic (GRO) com-

pounds, alsocalledpetroleumvolatileorganiccompounds

(PVOC), and the semivolatilediesel rangeorganic (DRO) com-

pounds—areanalyzeddifferentlydependingon theirboilingpoint

ranges.

Typicalmethods for the identificationof gasolineuseearlyand

lateeluting compounds todetermineananalyticalwindow for

total gasolinequantitation. Then,GCanalysisusespattern recog-

nition, the specific ratioof peaks thatmakeupaparticular com-

pound, to identify a fuel. If apattern fallswithin thiswindow, it

maybe reportedasgasolineandquantified. Difficultmatrices can

result inmisidentificationor poor quantitationof the sample, and

environmentaldegradation (i.e.,weathering) furthercomplicates

this analysis.

On January1, 1998, theMassachusettsDepartment ofEnviron-

mentalProtection (MADEP)promulgatedanewmethod, known

asVolatilePetroleumHydrocarbons (VPH) tobetter quantify

gasolines.Thismethod identifiesandevaluatesPVOCsbydiffer-

entiating and characterizing thearomaticand aliphatic fractionsof

gasolineusingaphoto-ionizationdetector (PID) anda flame ion-

izationdetector (FID) in series.Thedatagenerated from this

methodwill aid inevaluatinghumanhealthhazards thatmay result

fromexposure toPVOCs.Other states in theUSandprovinces in

Canadahaveadopted theVPHmethod for use in remediation, site

characterization, and toxicitydata (mixtures for othermethods are

listed in theUSTProduct Listing, lit. cat. #59617-A).

Difficultieswith theAnalysis

A largeproportionofVPH samples are soil.The soil isweighed in

the fieldandanequal amount ofmethanol is addedat the timeof

sampling. 100uLofmethanol extract is added to4.9mLofwater

and then is purged.Oneproblemwith this analysis is thatmost

purge-and-trapconcentratorswerenot designed tohave large

amountsofmethanol purgedonto their absorbent beds.The

VOCARB

™

3000andVOCARB

™

4000 trapshavedifficulty re-

taining

n

-pentaneand2-methylpentaneafter repeatedexposure to

methanol, causingpoor linearityof these compounds.We suggest

usingaBTEX trapbecauseof itsnon-polar properties.Youwill

experiencea slight decrease in response formethyl-

tert

-butyl-

ether, but itwill not compromiseyour detection limit.

ColumnSelection

All purge-and-trapmethods for this analysis result inbroad, early

elutingpeaks.Therefore, choosing the right chromatographic

column canprevent coelutionsandpoorquantitation. Many col-

umnsmaydrastically change thequantitationof aliphatic and

aromatic compounds, or suffer frompoor resolutionofmethanol

andmethyl-

tert

-butyl-ether or frompoor separationof pentane

and2-methylpentane. For optimized separationof light hydrocar-

bons and light gas additives, use theRtx

®

-502.2 column speci-

fied in theVPHmethod.

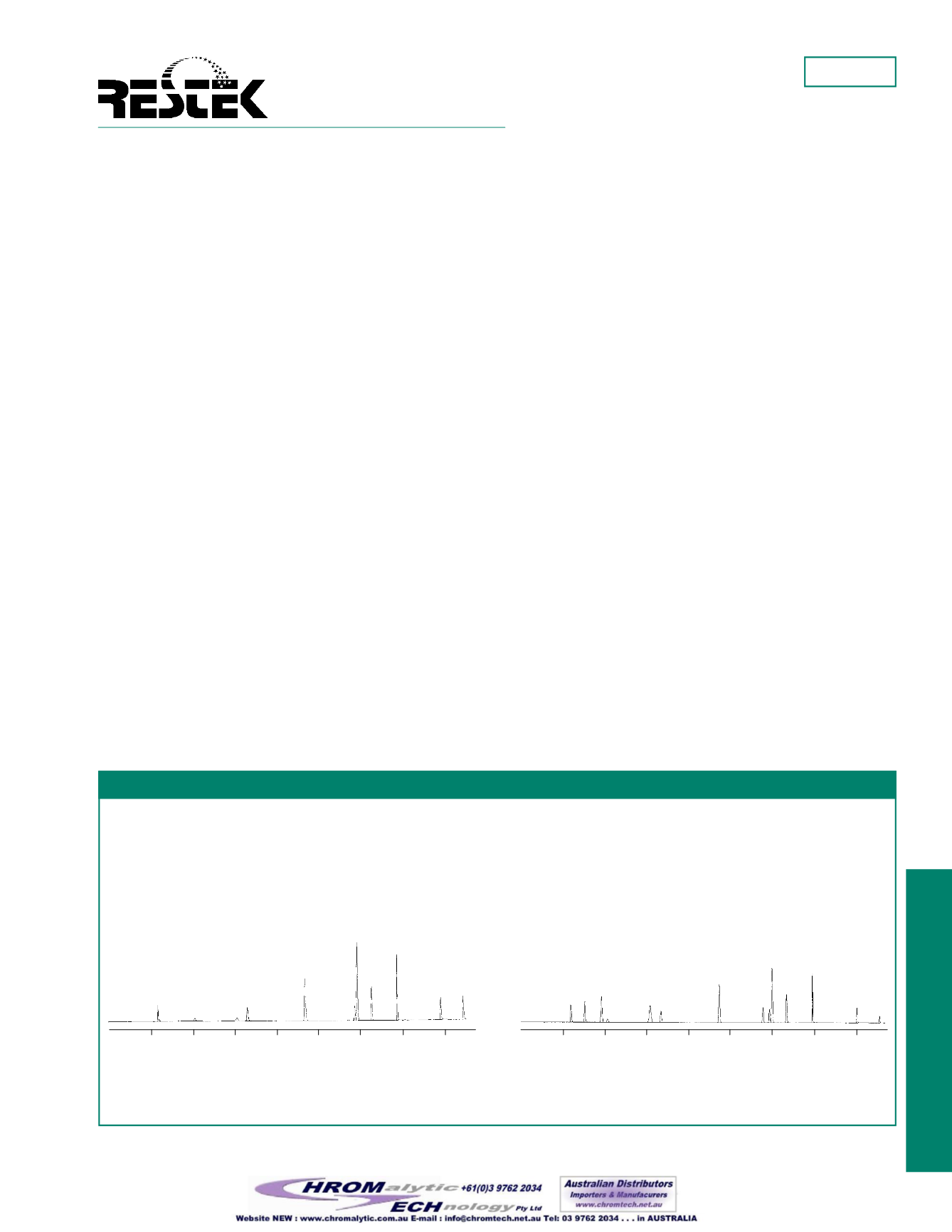

Figure1 shows the separationofVPHcompoundsonanRtx

®

-

502.2column, usingaPID (Figure1A) andanFID (Figure1B).

The first peak in thechromatogram ismethanol.Notice that it is

clearly separated from themethyl-

tert

-butyl-ether and

n

-pentane.

Figure1

To achieve optimumVPH analysis using anRtx

®

-502.2 column, usePID for aromatic compounds andFID for

aliphatic compounds.

Figure 1A: PID

105m, 0.53mm ID, 3.0µm (cat.# 10910).

Concentration:

on-column at levels listed;

Oven temp:

45°C to 90°C@ 3°C/min., to 140°@ 5°C/min.,

to 230°C@ 45°C/min. (hold 8min.);

Carrier gas:

helium@ 15mL/min.; Tekmar

®

Model LSC 2000;

Trap:

BTEX;

Purge:

helium@ 40mL/min.

for 11min.;

Dry purge:

2min.;

Desorb preheat:

245°C;

Desorb:

2min.@ 250°C;

Bake:

6min.@ 260°C.

Chromatograms courtesy of Severn Trent Laboratories, Burlington, VT.

1. methanol

2. methyl-

tert

-butyl-ether (60ng)

3. benzene (20ng)

4. toluene

5. ethylbenzene (20ng)

6.

p

+

m

-xylene (40ng ea.)

7.

o

-xylene (40ng)

8. 1,2,4-trimethylbenzene (40ng)

1. methanol

2.

n

-pentane (40ng)

3. 2-methylpentane (60ng)

4. methyl-

tert

-butyl-ether (60ng)

5. 2,2,4-trimethylpentane (60ng)

6. benzene (20ng)

7. toluene

8.

n

-nonane

9. ethylbenzene (20ng)

10.

p

+

m

-xylene (40ng ea.)

11.

o

-xylene (40ng)

12. 1,2,4-trimethylbenzene (40ng)

13. naphthalene (40ng)

14. 2,5-dibromotoluene (ss)

9. naphthalene (40ng)

10. 2,5-dibromotoluene (ss)

Figure 1B: FID

min. 4

8

12

16

20

24

28

32

1

7

2 3

4

5 6

89

10

11

12

13

14

1

7

2

3

4

5

6

8

9 10

min. 4

8

12

16

20

24

28

32