MRC-2014Hot.svg - page 235

APPENDIX

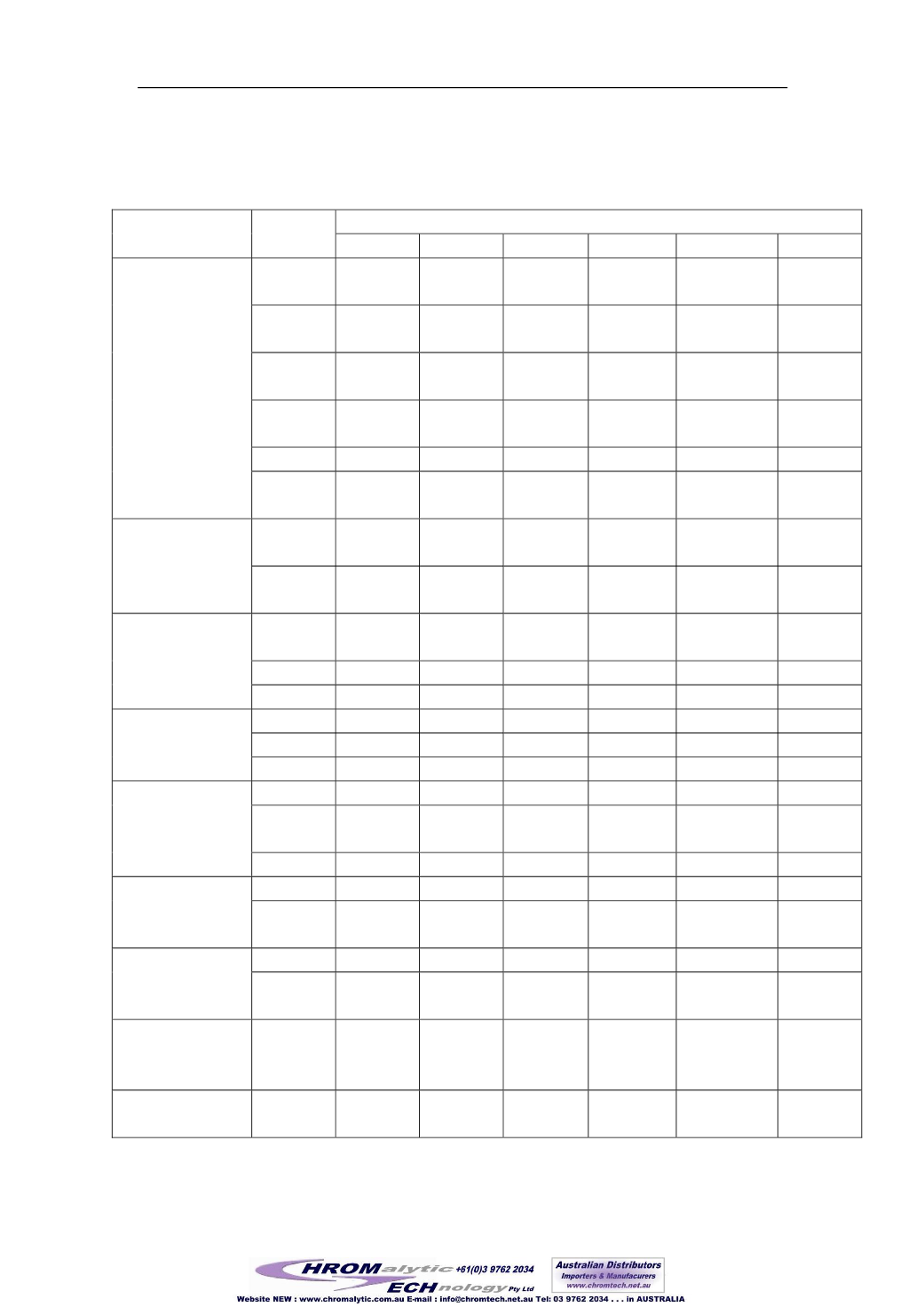

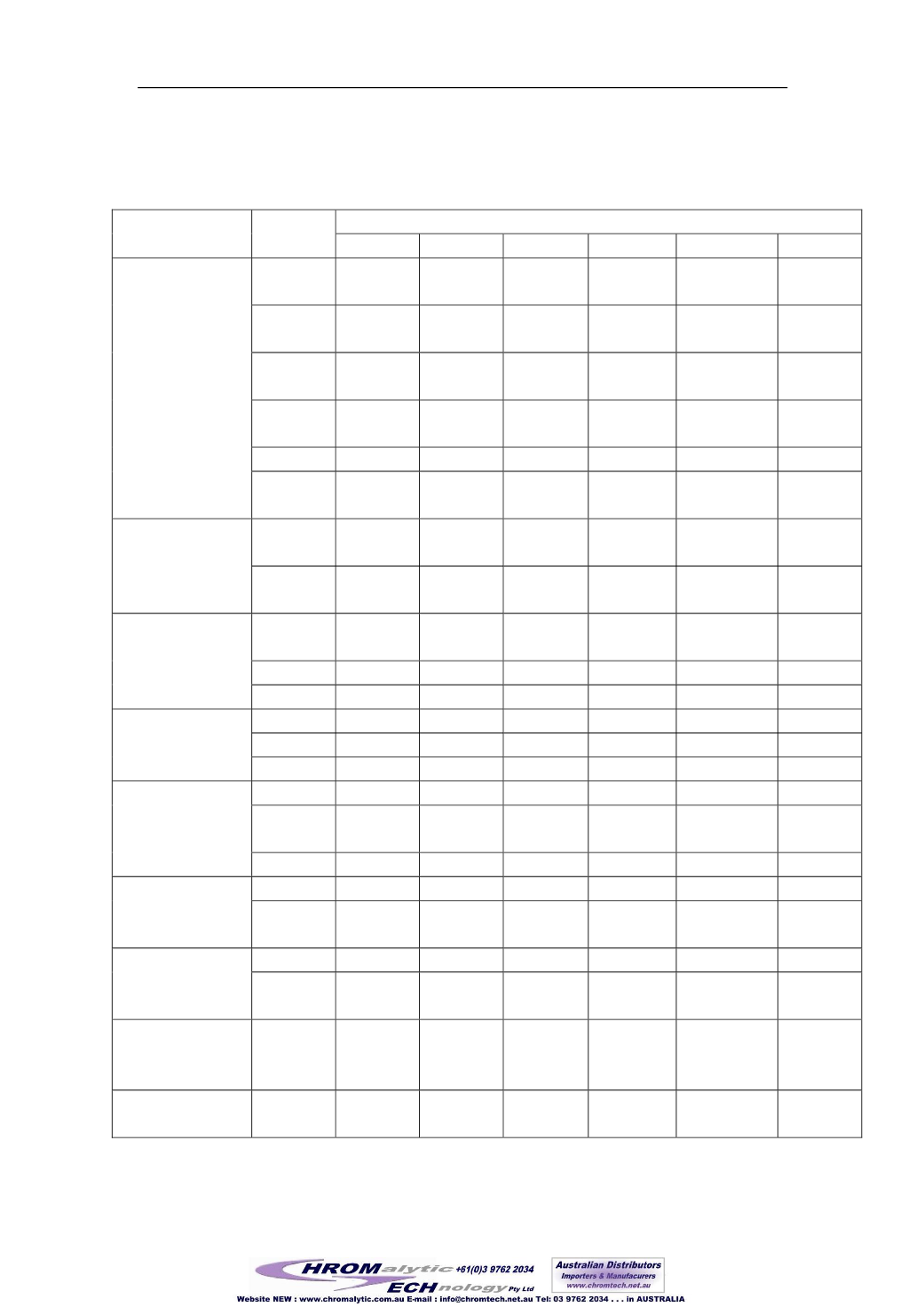

Table 1

Impact device

Material

Method

D/DC

D+15

C

G

E

DL

HRC

20

~

68.5

19.3

~

67.9

20.0

~

69.5

22.4

~

70.7 20.6

~

68.2

HRB

38.4

~

99.6

47.7

~

99.9

37.0

~

99.9

HRA

59.1

~

85.8

61.7

~

88.0

HB

127

~

651

80

~

638 80

~

683 90

~

646

83

~

663 81

~

646

HV

83

~

976 80

~

937 80

~

996

84

~

1042 80

~

950

Steel and cast

steel

HS

32.2

~

99.5

33.3

~

99.3

31.8

~

102.1

35.8

~

102.6

30.6

~

96.8

HRC

20.4

~

67.1

19.8

~

68.2

20.7

~

68.2

22.6

~

70.2

Cold work

tool steel

HV

80

~

898 80

~

935 100

~

941

82

~

1009

HRB

46.5

~

101.7

HB

85

~

655

Stainless steel

HV

85

~

802

HRC

HB

93

~

334

92

~

326

Grey cast iron

HV

HRC

HB

131

~

387

127

~

364

Nodular cast

iron

HV

HB

19

~

164

23

~

210 32

~

168

Cast aluminium

alloys

HRB

23.8

~

84.6

22.7

~

85.0

23.8

~

85.5

HB

40

~

173

BRASS(copper-

zinc alloys)

HRB

13.5

~

95.3

BRONZE(copp

er-aluminium/ti

n alloys)

HB

60

~

290

Wrought copper

alloys

HB

45

~

315

17

207

1...,225,226,227,228,229,230,231,232,233,234

236,237,238,239,240,242-243,244-245,246-247,248-249,250-251,...