3.2 Impact Device Selection

Refer to Appendix Table 1 and Table 3 for selection of impact device.

3.3 Preparation of the Sample Surface

Preparation for sample surface should conform to the relative requirement in Appendix

Table 3.

In the preparation processing for sample surface, the hardness effect of being heated or

cold processing on the surface of sample should be avoided.

Too big roughness of the being measured surface could cause error. So, the surface of

the sample to be measured must appear metallic luster, smoothing and polish, without

oil stain.

Support of test sample. Support is no necessary for heavy sample. Medium-weight parts

must be set on the smoothing and stable plane. The sample must set absolutely

equability and without any wobble.

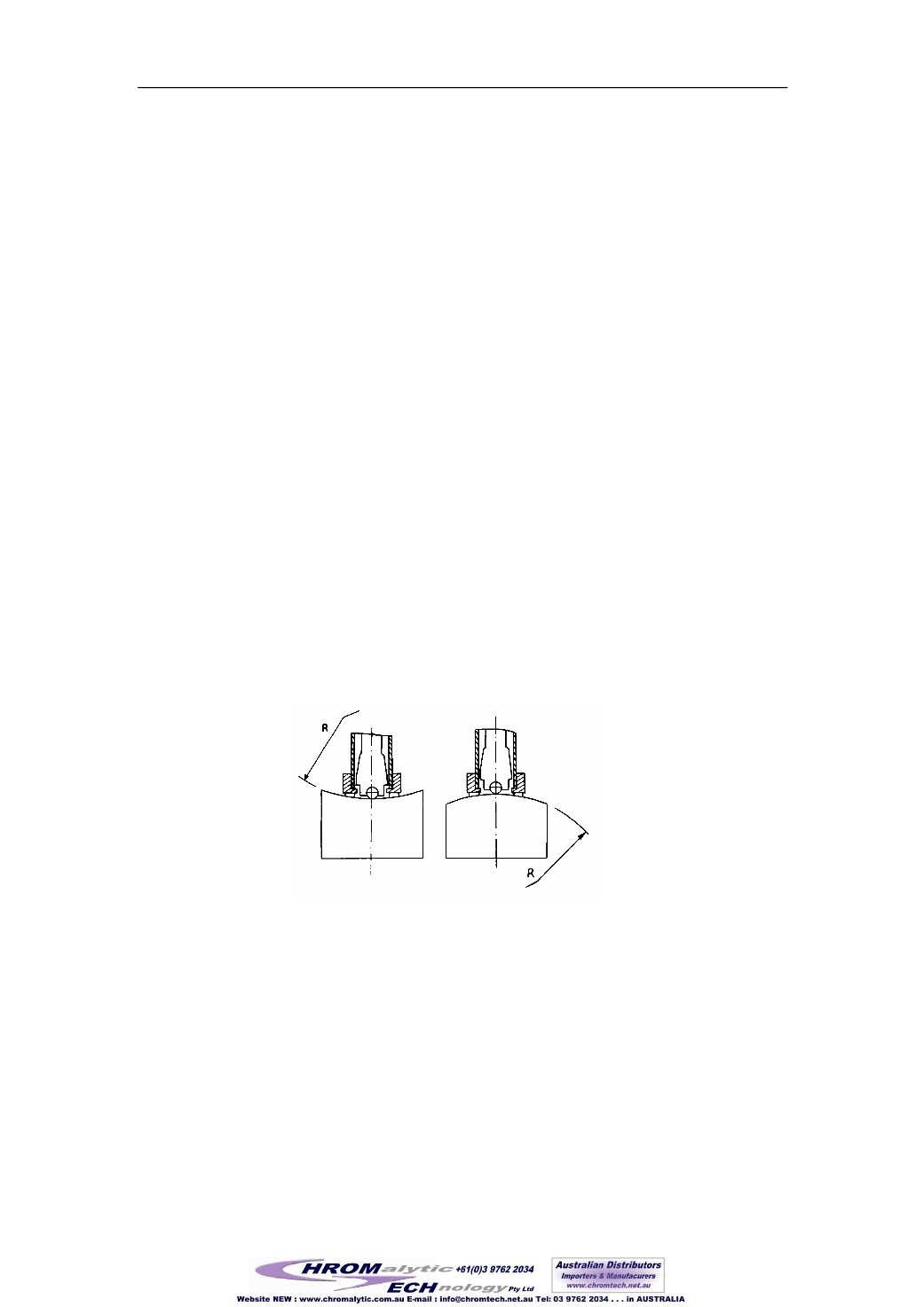

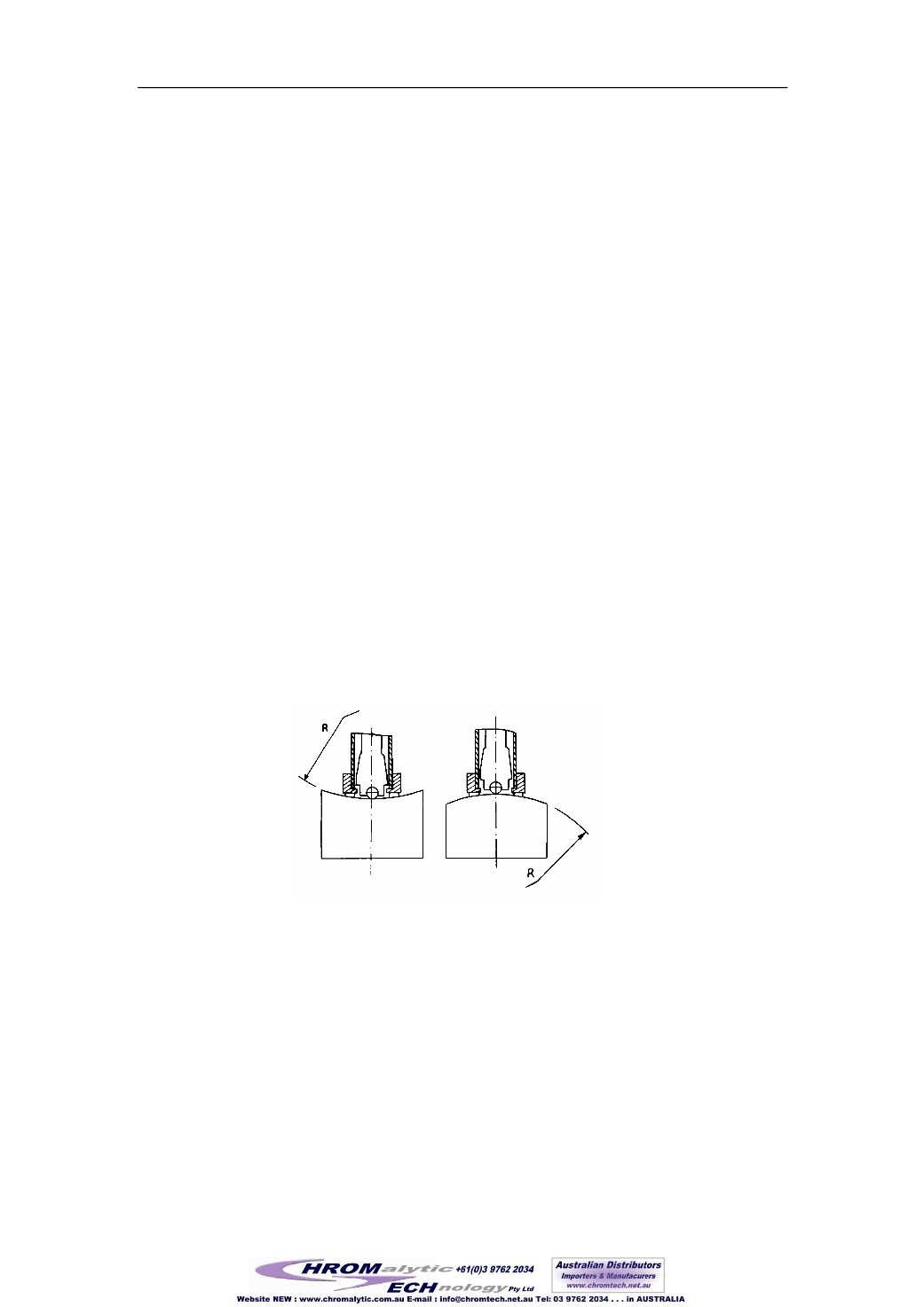

Curved surface: The best testing surface of sample is flat. When the curvature radius R

of the surface to be tested is smaller than 30mm (D, DC, D+15,C, E and DL type of

impact device) and smaller than 50mm (G type of impact device), the small support ring

or the shaped support rings should be chosen.

The sample should have enough thickness, minimum thickness of sample should

conform to Table 3.

For the sample with hardened layer on surface, the depth of hardened layer should

conform to Table 3.

Coupling. Light-weight sample must be firmly coupled with a heavy base plate. Both

coupled surface must be flat and smooth, and there is no redundant coupling agent

existing. The impact direction must be vertical to the coupled surface. When the sample

is a big plate, long rod or bending piece, it can be deformed and become unstable,

even though its weight and thickness is big enough, and accordingly, the test value may

not be accurate. So the sample should be reinforced or supported at its back.

Magnetism of the sample itself should be avoided.

9

199