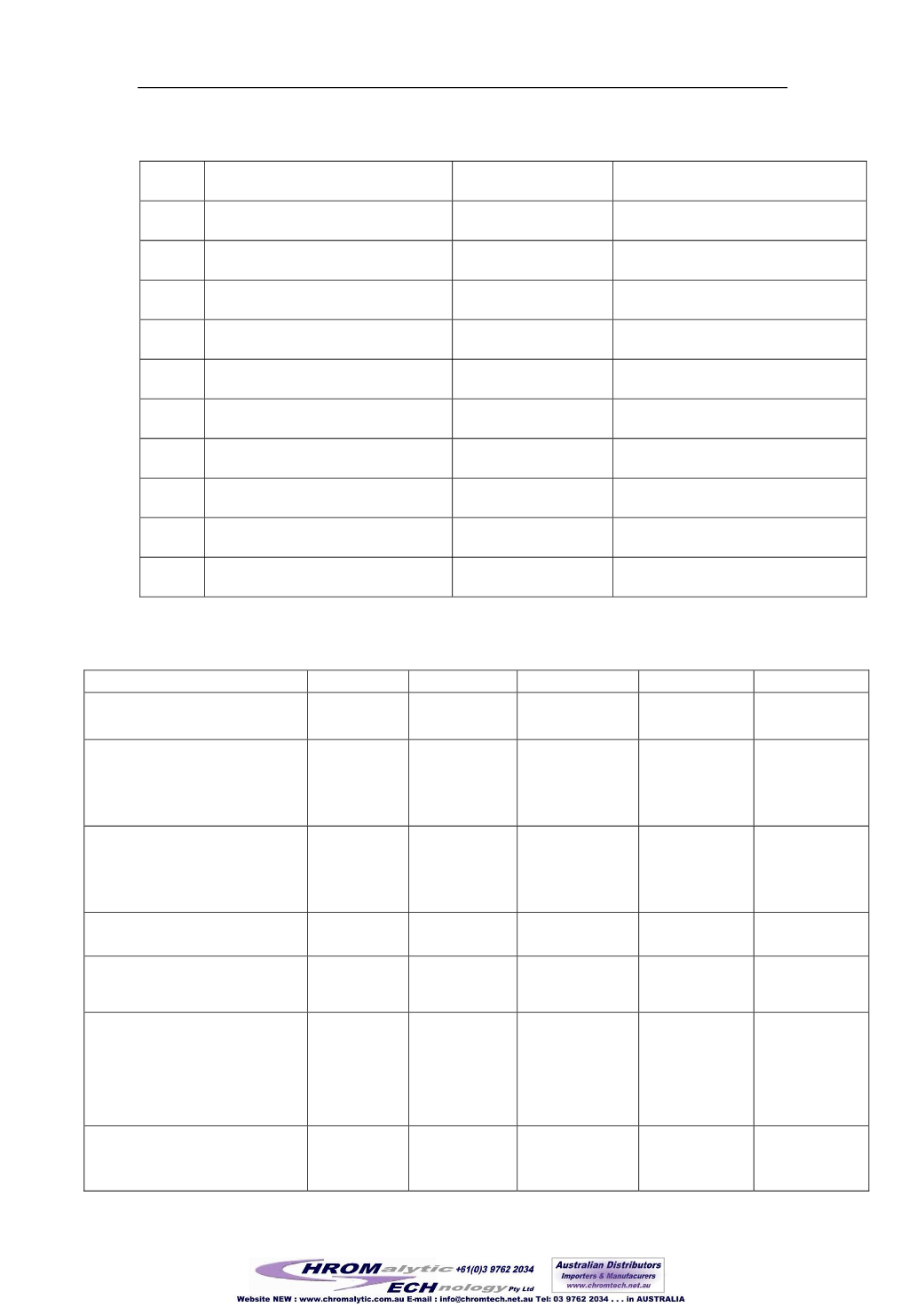

Table 2

No.

Material

HLD

Strength

σ

b

(MPa)

1

Mild steel

350

~

522

374

~

780

2

High-Carbon steel

500

~

710

737

~

1670

3

Cr steel

500

~

730

707

~

1829

4

Cr-V steel

500

~

750

704

~

1980

5

Cr-Ni steel

500

~

750

763

~

2007

6

Cr-Mo steel

500

~

738

721

~

1875

7

Cr-Ni-Mo steel

540

~

738

844

~

1933

8

Cr-Mn-Si steel

500

~

750

755

~

1993

9

Super strength steel

630

~

800

1180

~

2652

10

Stainless steel

500

~

710

703

~

1676

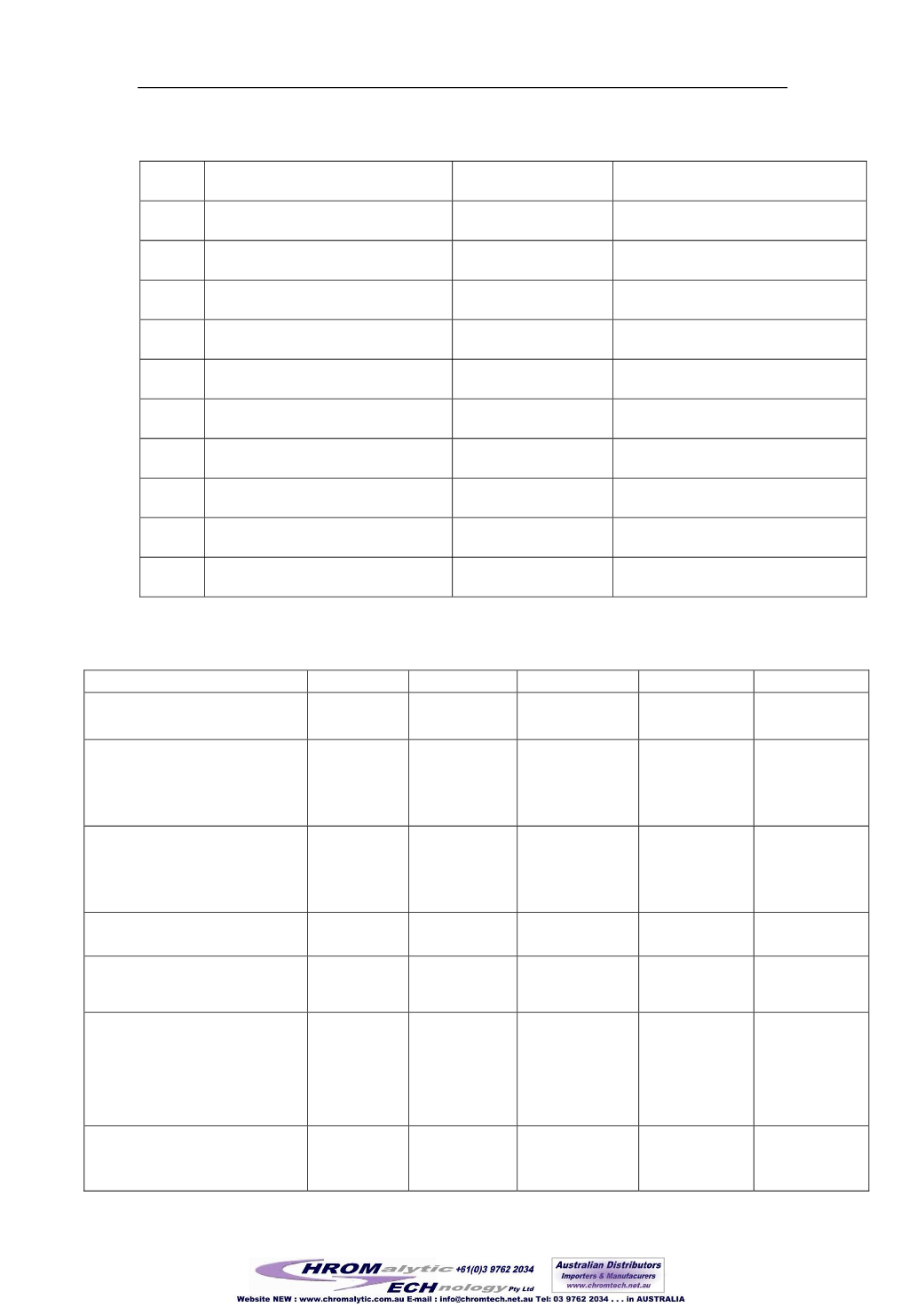

Table 3

Type of impact device DC(D)/DL

D+15

C

G

E

Impacting energy

Mass of impact body

11mJ

5.5g/7.2g

11mJ

7.8g

2.7mJ

3.0g

90mJ

20.0g

11mJ

5.5g

Test tip hardness:

Dia. Test tip:

Material of test tip:

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten

carbide

1600HV

3mm

Tungsten

carbide

1600HV

5mm

Tungsten

carbide

5000HV

3mm

synthetic

diamond

Impact device diameter:

Impact device length:

Impact device weight:

20mm

86(147)/

75mm

50g

20mm

162mm

80g

20mm

141mm

75g

30mm

254mm

250g

20mm

155mm

80g

Max. hardness of

sample

940HV

940HV

1000HV

650HB

1200HV

Mean roughness value

of sample surface Ra:

1.6

μ

m

1.6

μ

m

0.4

μ

m

6.3

μ

m

1.6

μ

m

Min. weight of sample:

Measure directly

Need support firmly

Need coupling tightly

>5kg

2

~

5kg

0.05

~

2kg

>5kg

2

~

5kg

0.05

~

2kg

>1.5kg

0.5

~

1.5kg

0.02

~

0.5kg

>15kg

5

~

15kg

0.5

~

5kg

>5kg

2

~

5kg

0.05

~

2kg

Min. thickness of sample

Coupling tightly

Min. layer thickness for

5mm

5mm

1mm

10mm

5mm

18

208