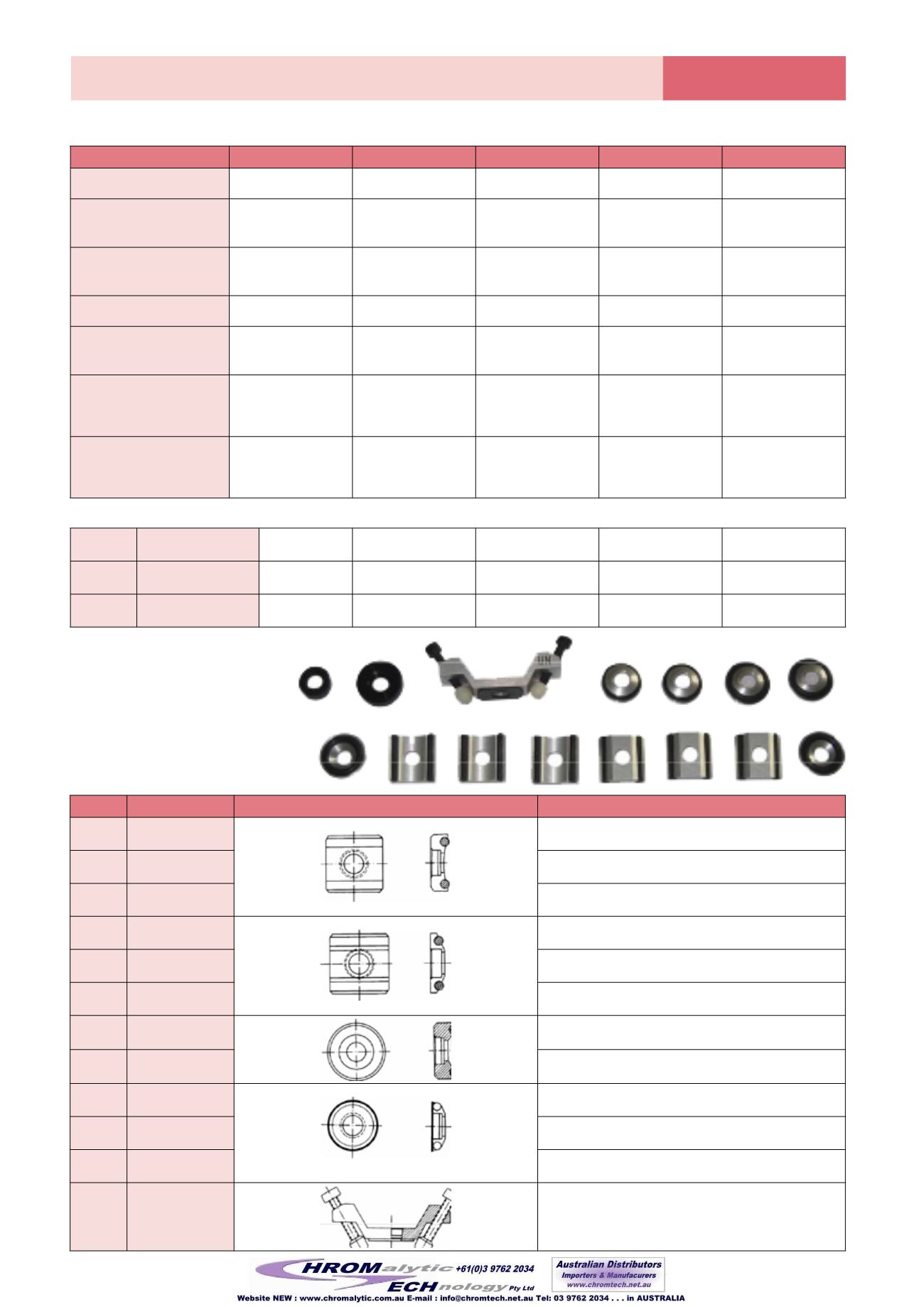

METERS

Hardness

Type of impact device DC(D)/DL

D+15

C

G

E

Impacting energy

Mass of impact body

11mJ

5.5g/7.2g

11mJ

7.8g

2.7mJ

3.0g

90mJ

20.0g

11mJ

5.5g

Test tip hardness:

Dia. Test tip:

Material of test tip:

1600HV

3mm

Tungsten carbide

1600HV

3mm

Tungsten carbide

1600HV

3mm

Tungsten carbide

1600HV

5mm

Tungsten carbide

5000HV

3mm

synthetic diamond

Impact device diam.:

Impact device length:

Impact device weight:

20mm

86(147)/75mm

50g

20mm

162mm

80g

20mm

141mm

75g

30mm

254mm

250g

20mm

155mm

80g

Max. hardness of

sample

940HV

940HV

1000HV

650HB

1200HV

Mean roughness

value of sample

surface Ra:

1.6μm

1.6μm

0.4μm

6.3μm

1.6μm

Min. weight of sample:

Measure directly

Need support firmly

Need coupling tightly

>5kg

2 ~ 5kg

0.05 ~ 2kg

>5kg

2 ~ 5kg

0.05 ~ 2kg

>1.5kg

0.5 ~ 1.5kg

0.02 ~ 0.5kg

>15kg

5 ~ 15kg

0.5 ~ 5kg

>5kg

2 ~ 5kg

0.05 ~ 2kg

Min. thickness of

sample Coupling tightly

Min. layer thickness

for surface hardening

5mm

≥

0.8mm

5mm

≥

0.8mm

1mm

≥

0.2mm

10mm

≥

1.2mm

5mm

≥

0.8mm

MRC.07.14

Testing conditions:

Hardness

300HV

Indentation diam.

Depth of indentation

0.54mm

24μm

0.54mm

24μm

0.38mm

12μm

1.03mm

53μm

0.54mm

24μm

Hardness

600HV

Indentation diam.

Depth of indentation

0.54mm

17μm

0.54mm

17μm

0.32mm

8μm

0.90mm

41μm

0.54mm

17μm

Hardness

800HV

Indentation diam.

Depth of indentation

0.35mm

10μm

0.35mm

10μm

0.35mm

7μm

-

-

0.35mm

10μm

Size of tip indentation:

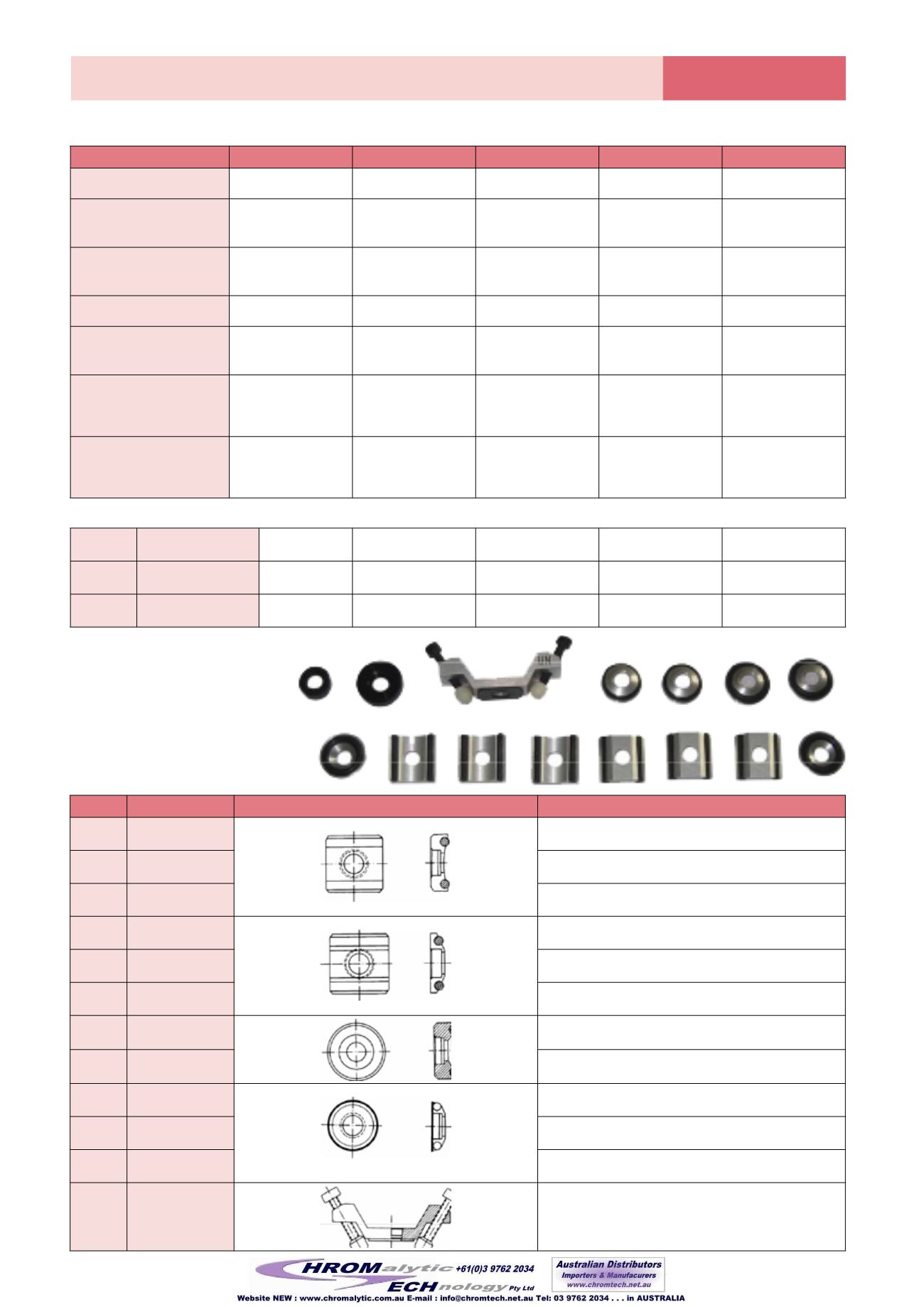

Support rings for Shaped Materials:

Other type of support rings:

No.

Type Sketch of non-conventional Supporting ring

Remarks

1

Z10-15

For testing cylindrical outside surface R10 ~ R15

2

Z14.5-30

For testing cylindrical outside surface R14.5 ~ R30

3

Z25-50

For testing cylindrical outside surface R25 ~ R50

4

HZ11-13

For testing cylindrical inside surface R11 ~ R13

5

HZ12.5-17

For testing cylindrical inside surface R12.5 ~ R17

6

HZ16.5-30

For testing cylindrical inside surface R16.5 ~ R30

7

K10-15

For testing spherical outside surface SR10 ~ SR15

8

K14.5-30

For testing spherical outside surface SR14.5 ~ SR30

9

HK11-13

For testing spherical inside surface SR11 ~ SR13

10 HK12.5-17

For testing spherical inside surface SR12.5 ~ SR17

11 HK16.5-30

For testing spherical inside surface SR16.5 ~ SR30

12

UN

For testing cylindrical outside surface,

radius adjustable R10 ~ ~

~

212