4 Testing Program

4.1 Start-Up

Insert the plug of the impact device into the socket of impact device on the instrument.

Press the key

,

now power is on. The instrument is in working mode.

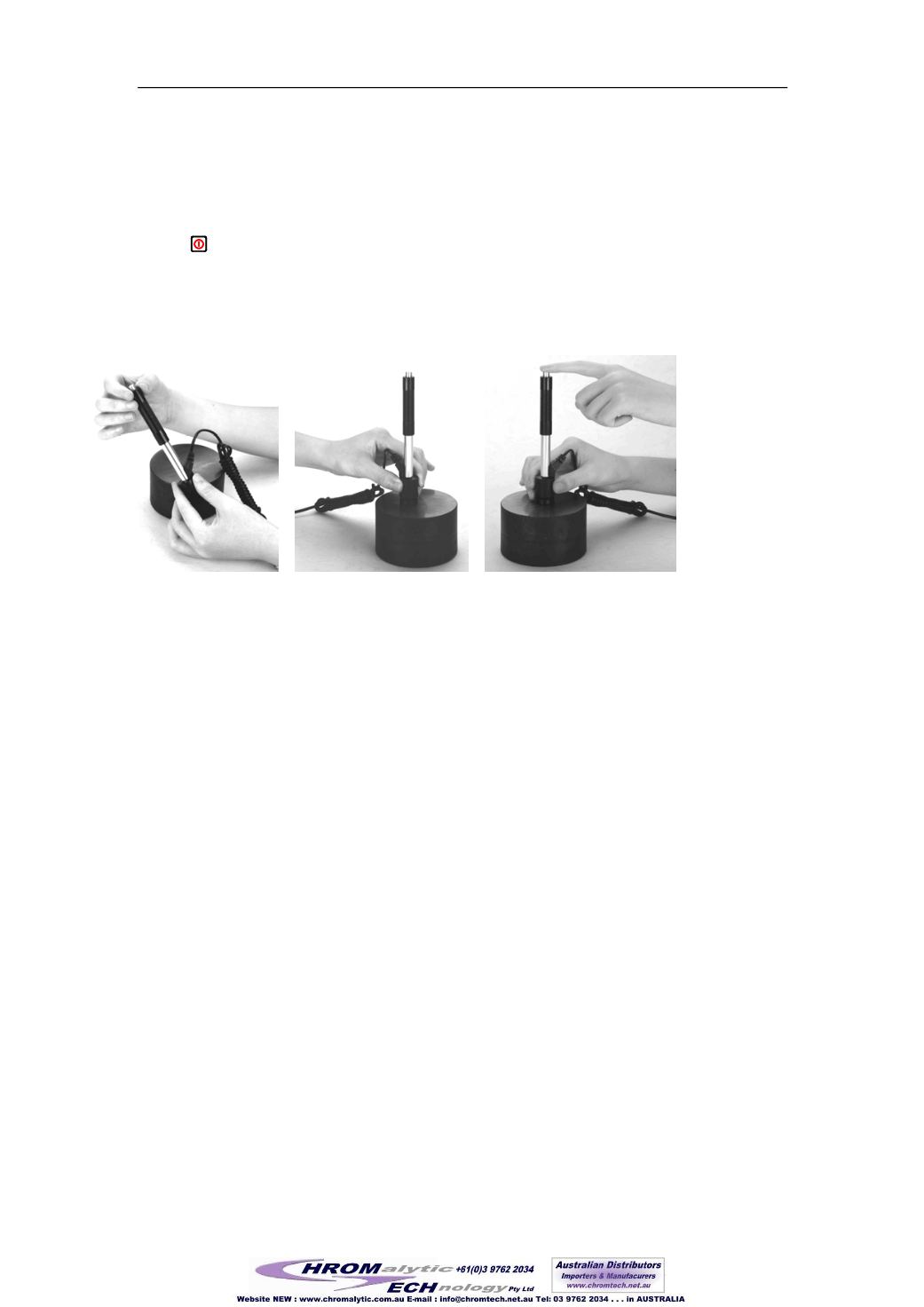

4.2 Loading

Pushing the loading-tube downwards until contact is felt. Then allow it to slowly return to

the starting position or using other method locking the impact body.

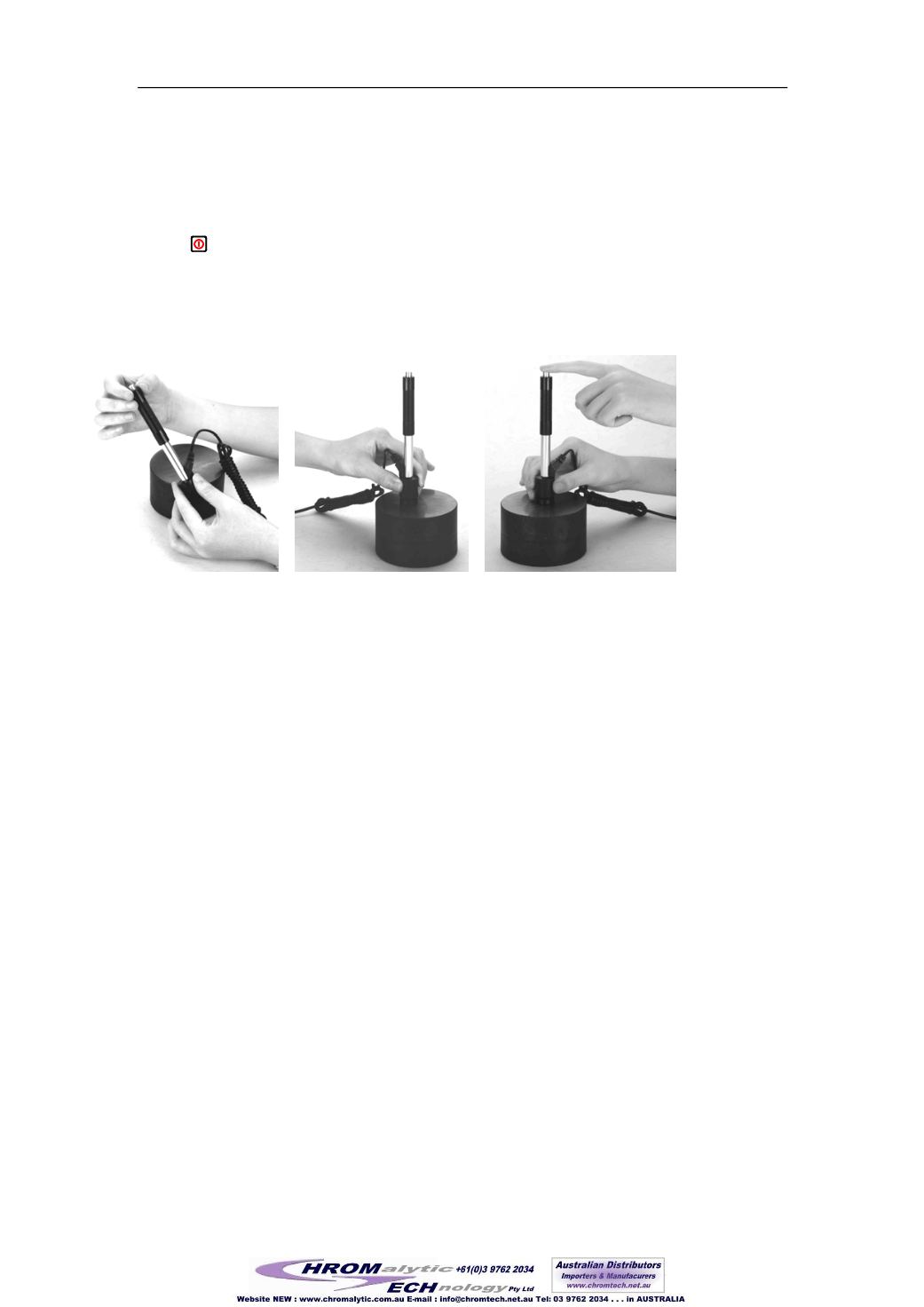

4.3 Localization

Press the impact device supporting ring firmly on the surface of the sample, the impact

direction should be vertical to the testing surface.

4.4 Testing

Press the release button on the upside of the impact device to test. The sample and the

impact device as well as the operator are all required to be stable now. The action

direction should pass the axis of the impact device.

Each measure area of the sample usually need 3 to 5 times of testing operation. The

result data dispersion should not more than mean value

±

15HL

。

The distance between any two impact points or from the center of any impact point to

the edge of testing sample should conform to the regulation of Table 4-1.

If want accurate conversion from the Leeb hardness value to other hardness value,

contrastive test is needed to get conversion relations for the special material. Use

inspection qualified Leeb hardness tester and corresponding hardness tester to test at

the same sample respectively. For each hardness value, each measure

homogeneously 5 points of Leeb hardness value in the surrounding of more than three

indentations which need conversion hardness, using Leeb hardness arithmetic average

value and corresponding hardness average value as correlative value respectively,

make individual hardness contrastive curve. Contrastive curve at least should include

three group of correlative data.

Table 4-1

10

200