Restek Corporation • (800) 356-1688 • (814) 353-1300 •

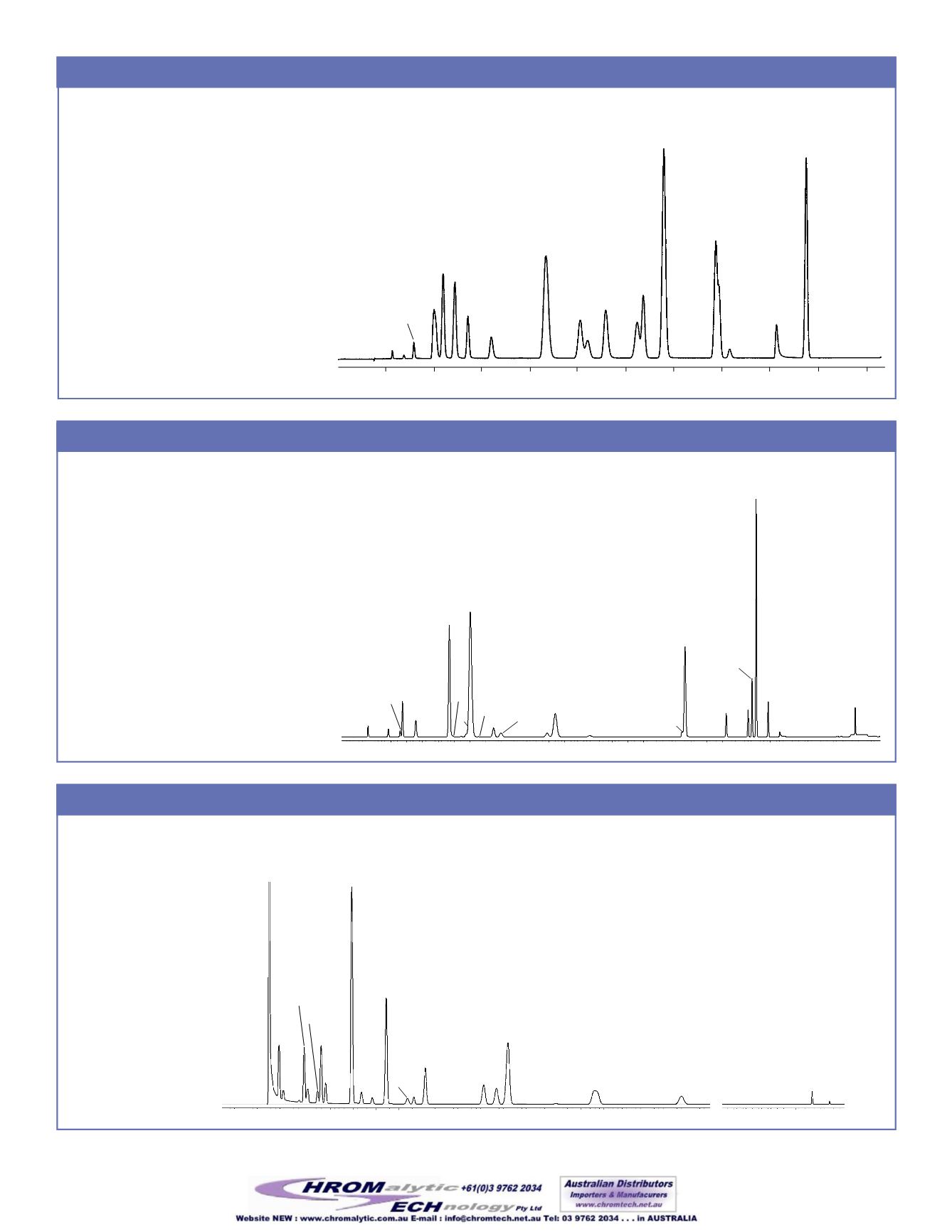

30m, 0.53mm ID, 5.0µmRtx

®

-G27with 5m phenylmethyl Integra-Guard

™

(cat.# 10279-126).

Headspace injection of 24 common residual solvents for pharmaceutical processing. Prepared to equal about 500ppm in

the bulk pharmaceutical. Samples shaken and heated at 90°C for 15minutes, 1mL headspace injection.

Oven temp.:

35°C (hold 10min.) to 100°C@ 5°C/min., to 240°C@ 25°C/min. (hold 5min.);

Inj./det. temp.:

220°C/240°C;

FID sensitivity:

1.05 x 10

-11

AFS;

Carrier gas:

helium, 35cm/sec. set@ 35°C;

Split ratio:

2:1.

2

3

4

1

2

min.

4

10

12

14

6

8

16

18

7,5,6 8

11,9

10

12

13

14

15

17,16,21

18

19

20

22

23

24

20

22

ethanol

1. ethylene oxide

2. methanol

3. diethyl ether

4. 1,1-dichloroethene

5. acetone

6. isopropanol

7. acetonitrile

8. methylene chloride

9.

n

-hexane

10.

n

-propanol

11. methyl ethyl ketone

12. ethyl acetate

13. tetrahydrofuran

14. chloroform

15. 1,1,1-trichloroethane

16. carbon tetrachloride

17. benzene*

18. 1,2-dichloroethane

19. heptane

20. trichloroethylene

21.

n

-butanol

22. 1,4-dioxane

23. pyridine

24. toluene

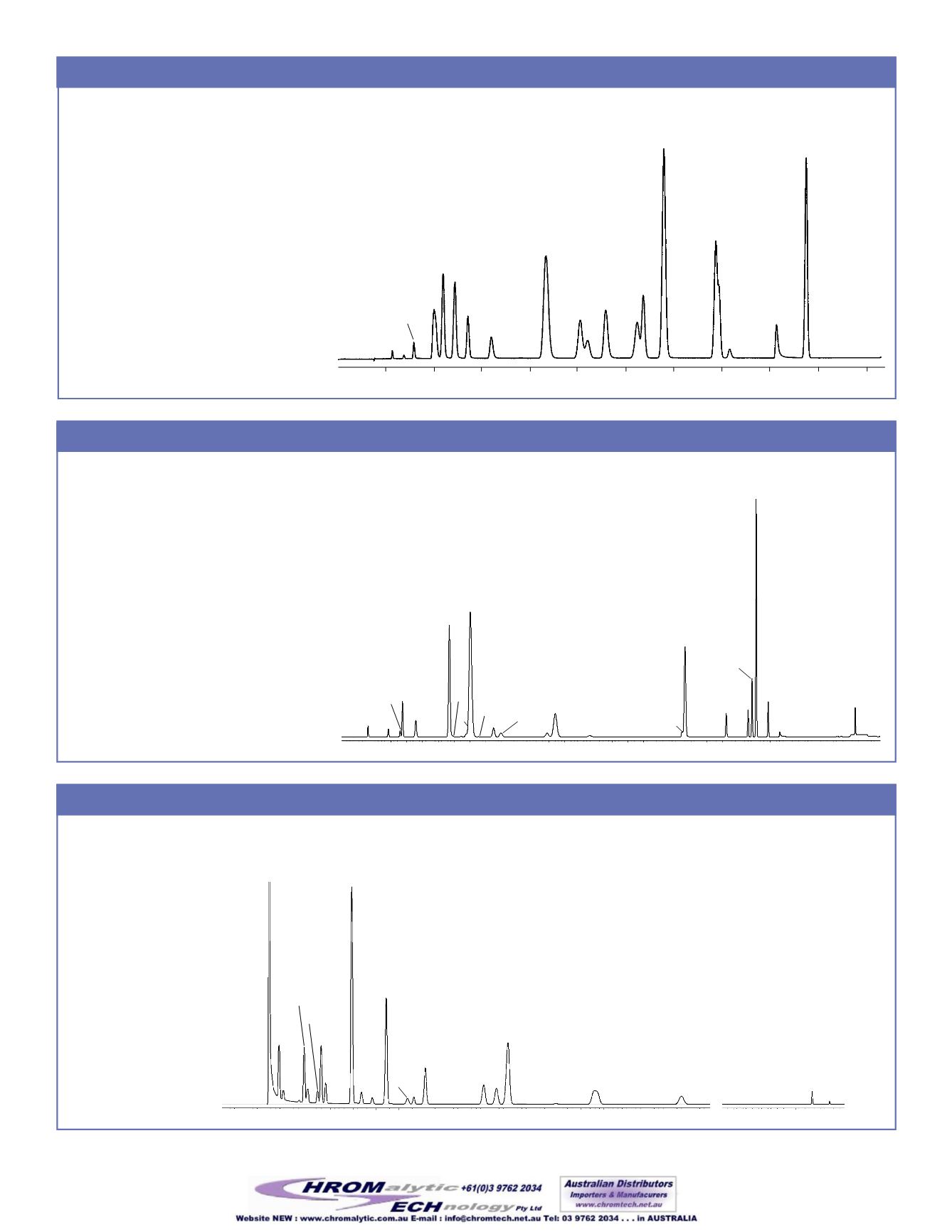

30m x .53mm ID x 3.0mmRtx

®

-G43 (cat.# 16085-126).

Headspace injection of 28Class 1 and 2 residual solvents for pharmaceutical

processing. Prepared at the regulatory limit concentration. Samples shaken and

heated at 80°C for 15minutes, 1mL headspace injection.

Oven temp.:

40°C (hold 20min.) to 240°C@ 10°C/min. (hold 20min.);

Inj./det. temp.:

200°C/250°C;

FID sensitivity:

1.1 x 10

-11

AFS;

Carrier gas:

hydrogen@ 35cm/sec.;

Split ratio:

2:1.

1. methanol

2. 1,1-dichloroethene

3. acetonitrile

4. methylene chloride

(dichloromethane)

5. hexane (C6)

6.

cis

-1,2-dichloroethene

7. nitromethane

8. chloroform

9. cyclohexane

10. 1,1,1-trichloroethane

11. carbon tetrachloride

12. benzene*

13. 1,2-dimethoxyethane

14. 1,2-dichloroethane

15. trichloroethylene

(1,1,2-trichlorethene)

16. methylcyclohexane

17. 1,4-dioxane

18. pyridine

19. toluene

20. 2-hexanone

21. chlorobenzene

22. DMF

23. ethylbenzene

24.

m

-xylene

25.

p

-xylene

26.

o

-xylene

27. N,N-dimethylacetamide

28. 1,2,3,4-

tetrahydronaphthalene

min. 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34

1 2

3

4

5

6 9,10

7

8 11

12 13,14

15

16

17

18

19

20 21

22,23

24,25

26

27

28

Same peak list as Figure 5.

min. 1 2 3 4 5 6 7 8 9 10 26 28 30

28

27

22

21

18, 26

7

24

25 23

20

14

17

19

3 8

6, 15

12

4

1

10, 11

16

2

5, 9

*Testing for benzene only requiredwhen

specified in the individual monograph.

*Testing for benzene only requiredwhen

specified in the individual monograph.

Figure 4

AnRtx

®

-G27 column resolvesmany solvents commonly used in pharmaceutical processing.

Figure 5

AnRtx

®

-G43 column shows excellent resolution of commonly-used pharmaceutical processing solvents.

EuropeanPharmacopoeiaClass 1 andClass 2 compounds at the regulation limit concentration.

*Testing for benzene only requiredwhen

specified in the individual monograph.

Figure 6

A Stabilwax

®

columnmakes an excellent confirmation column for commonly-used pharmaceutical processing solvents.

EuropeanPharmacopoeiaClass 1 andClass 2 compounds at the regulation limit concentration.

30m x .53mm ID x 0.5µmStabilwax

®

(cat.# 10640-126). Headspace injection of 28Class 1

and 2 residual solvents for pharmaceutical processing. Prepared at the regulatory limit

concentration. Samples shaken and heated at 80°C for 15minutes, 1mL headspace injection.

Oven temp.:

50°C (hold 20min.) to 165°C@ 6°C/min. (hold 20min.);

Inj./det. temp.:

200°C/250°C;

FID sensitivity:

1.1 x 10

-11

AFS;

Carrier gas:

hydrogen@ 35cm/sec.;

Split ratio:

2:1