RestekCorporation

(800) 356-1688

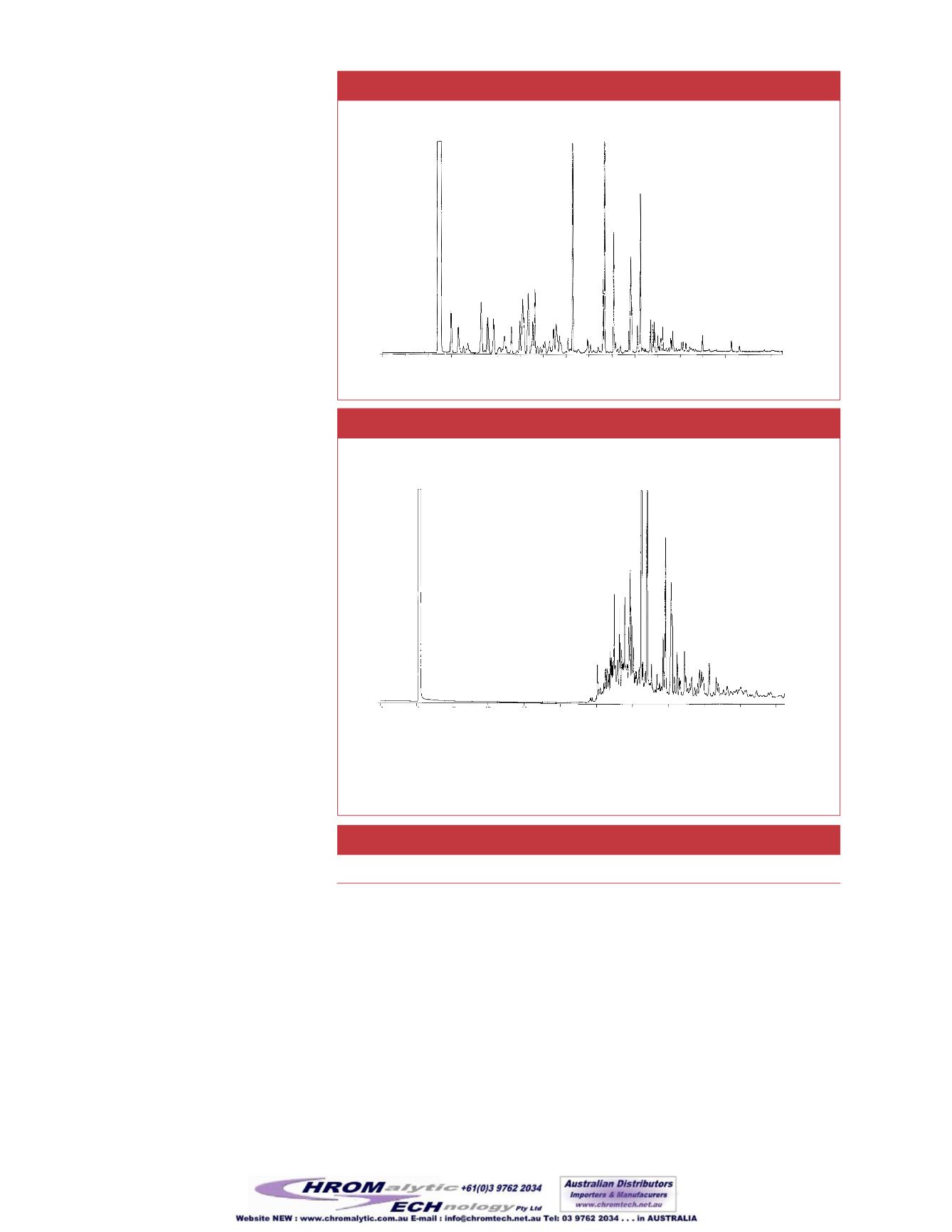

After establishing the correct conditions

toobtain complete resolutionof the test

mix components, the analystmust then

calibrate the instrument. In firedebris

analysis, this involves purchase and

preparationof common accelerants used

to ignite fireswith subsequent injection

into theGC.Quantitationof unknown

samples is not performed. The analyst

must providepositive identification to

the field investigators of any accelerants

found in the samples collected. Todo

this, the analystmust be able to

recognize typical chromatographic

patterns of each accelerant.

Figure2

shows the chromatographicpattern

obtained from an injectionof an

unleadedgasoline standard.

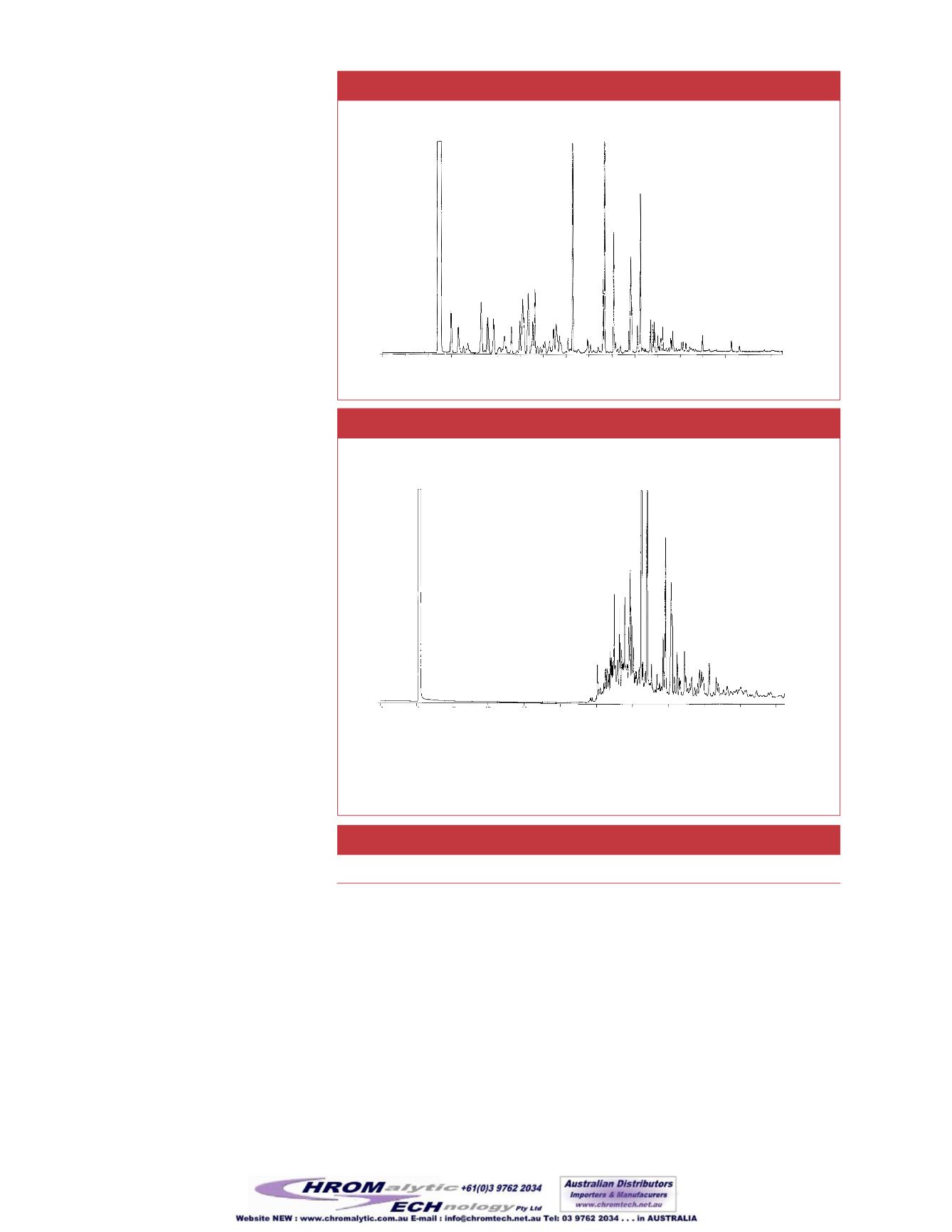

To further complicate this analysis,

many factorswill change the chromato-

graphicpatternobtained from fire

debris. The first isweatheringof the

material from the heat of the fire along

withdilutionofwater used to extin-

guish the blaze. Thisweathering can

dramaticallychange thechromato-

graphicpatternof thematerial. Typi-

cally, lower boilingmaterials are lost by

theheat, leaving thehigher boiling

compounds remaining. This typeof

weathering canbe simulated in the

laboratoryby evaporating thematerial

under controlled conditions. The

advantageof performing theevapora-

tion in the laboratory is that the exact

amount ofweight loss compared to the

original startingmaterial canbe

measured and controlled.

Figure3

shows the analysis of a 99%weathered

unleadedgasoline. Thegasolinehas

beenweathered to a 99%weight loss

and an exact concentration calibration

standardwas preparedwith the

remainingmaterial.By analyzing

knownweatheredproducts, the analyst

canmore readily recognize the typeof

original startingmaterial.

There are five basic classes of complex

petroleumdistillatesnormally identifi-

able in arson samples.A sixth class of

accelerants (Class 0) includes single

compounds sometimesusedand

identified.

Table I

shows the complete

list of classes, typical chromatographic

rangeof eachmaterial (basedupon

hydrocarbon elution), and examples of

each type.

UnleadedGasolineStandard (Unweathered)

Figure 3

UnleadedGasoline (99%Weathered)

Table I - TypicalHydrocarbons

Class #

Range Examples

1 LightPetroleum

C4-C8 Pocket lighter fuel, petroleum ethers,

some rubber cement solvents

2 Gasoline

C4-C12 Gasoline (ALL), some camping fuels

3 MediumPetroleum

C8-C12 Mineral spirits, paint thinners, some

Distillates (MPD)

torch fuels, some charcoal fuels, some

charcoal starters

4 Kerosene

C9-C16 Kerosene, No. 1FuelOil, Jet-AFuel

Oil, Jet-AFuel, some charcoal starters,

some torch fuels

5 HeavyPetroleum

C10-C23 No. 2FuelOil, Diesel Fuel #2

Distillates (HPD)

0 Unclassified

Variable Alcohols, acetone, toluene, some lamp

oils, camping fuels, lacquer thinners

Conditions for Figures 2& 3:

30m, 0.53mm ID, 1.50µmRtx

®

-1 (cat.# 10170).

Oven temp.:

40°C (hold 3min.) to 75°C@ 15°C/min. to 275°C@ 20°C/min. (hold 5min.);

Inj./det. temp.:

250°C/285°C;

Carrier gas:

hydrogen;

Linear velocity:

50cm/sec. set @ 40°C;

FID sensitivity:

4.10 x 10

-9

AFS

Split ratio:

30:1

Figure 2

min. 2 4 6 8 10

14 16 18 20

12

22 24 26 28 30 32 34

4

8 12 16 20 24

32 36 40 44

28

min.