2

Restek Corporation • (800) 356-1688 •

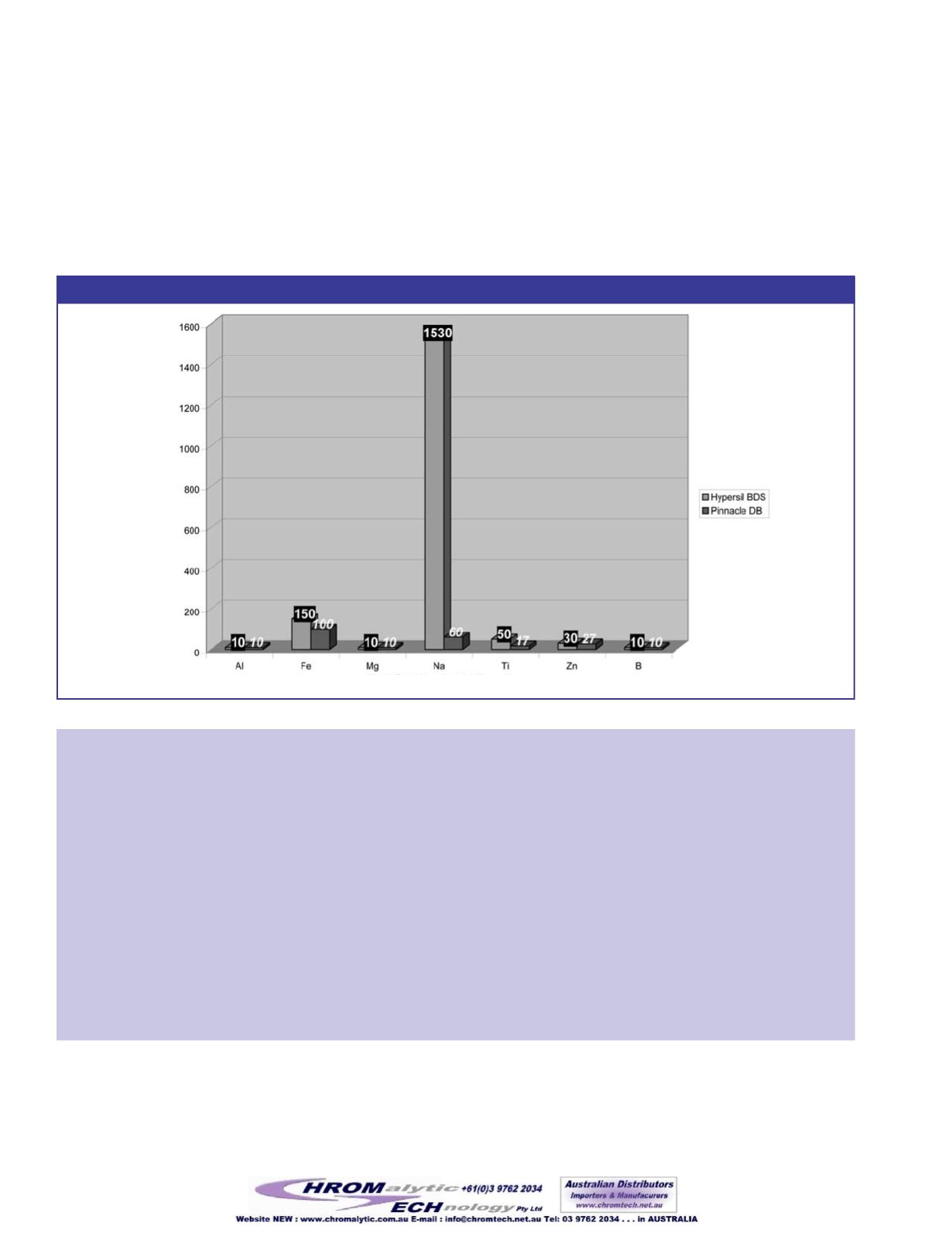

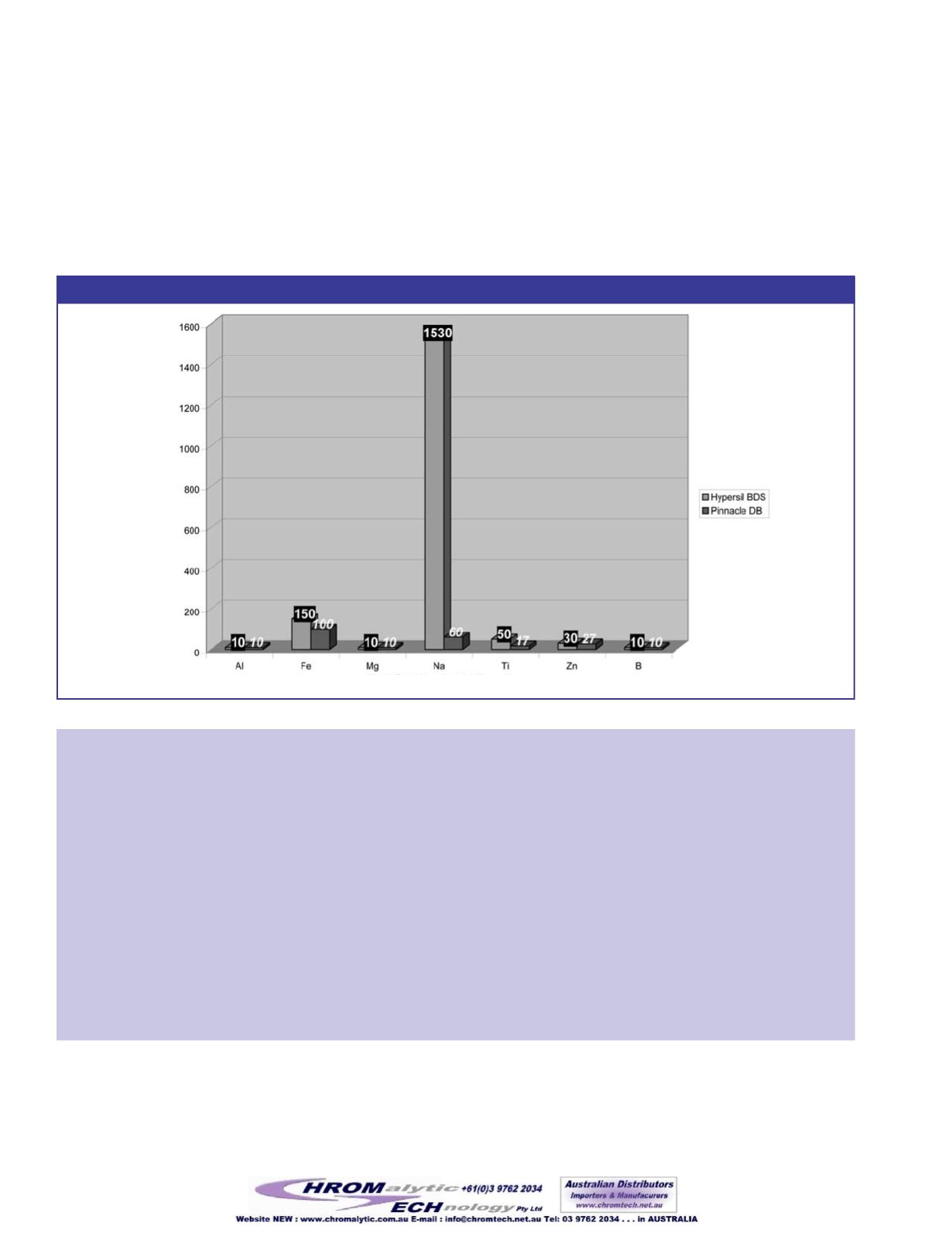

For certainphysical parameterswe intentionally deviated from

Hypersil

®

BDSmaterial - totalmetals content, for example. Fewer

metal ions on the surface of a silica particlemake for sharper and

more symmetric peaks for basic analytes.Our newmanufacturing

process stripsmetals from the silica surface, and smoothes the sur-

face aswell. Figure 4 compares the content of variousmetals in

Pinnacle

™

DB andHypersil

®

BDSmaterials. For everymetalmeas-

ured, Pinnacle

™

DB silica andHypersil

®

BDS silica have equivalent

content, or the content inPinnacle

™

DB is lower.

Of course,what reallymatters is how separations onPinnacle

™

DB

columns andHypersil®BDS columns compare. Figures 5–11 pair

Figure 4: Consistently lowmetals content inPinnacle

™

DB silica ensures sharper,more symmetric peaks for basic analytes.

chromatograms for various analytemixes fromC18 bondedphase

versions of the two silicas; eachpairwas obtainedusing the same

instrument andmobile phase.Note the similarity in retention,

asymmetry, and efficiency in each set of chromatograms.

Behavior of eachof these analyteswill vary, basedondifferences for

factors such as carbon load, liganddensity, degree of base deactiva-

tion, endcapping, andmetals content.Columns that are similar for

these characteristics shouldprovide similar chromatography.

Figures 5–11 show a Pinnacle

™

DBC18 column and aHypersil

®

BDS columnperformnearly identically.

Metal Type

ppm

(test limit is 10ppm)

How important ismetals content?

Silicamanufacturers andmost chromatographerswell know thatmetals, especiallymetal ions, on the surface of a silica particle negative-

ly affect peak symmetry andotherwise interferewith chromatography, particularly for basic analytes.Consequently, silicamanufacturers

use various treatments to eliminate surfacemetals or prevent contact between surfacemetals and sample components.

Silicas that have a highmetal content – especially sodium – are structurally inferior to silicas containing small amounts of metals. To

strengthen silica particles containing high concentrations of sodium andothermetals, somemanufacturers use an annealing process to

embed the sodium into the framework of the particles.Although annealing imparts strength to the particles, it destroys some of their

useable surface area.Worse, as the particles age or crack, shieldedmetals that were embedded in the silica through the annealing proce-

dure, and thereby escaped surface deactivation treatments, are re-exposed towreakhavocwith a separation. The analyst observes loss of

base deactivation and further erosionof the particles’ stability inhighly aqueousmobile phases.

Pinnacle

™

DB silica has a particularly low total sodium value; it does not need annealing to impart strength, as strength comes from

Restek’s use of self-assembledmaterials technology. By removing excessmetals andother impurities,wemake amore rugged silica. This

means a potentially longer lifetime for a columnmade from thismaterial, andmore consistent peak shapes for bases as the column ages.

Lowering totalmetals content during the creationof the product increases the usable lifetime of the product.