Restek Corporation • (800) 356-1688 • (814) 353-1300 •

The FDAhas defined two approaches to testing food contact

materials: migration studies versus residual studies. Inmigra-

tion studies, food-simulating solvents are used tomodel the

amount ofmaterial that migrates into the product. This is per-

formed under worst-case, intended-use conditions. Changes in

the food or ingredients used, such as a change in the fat content,

can affect themigration of compounds out of the packaging

material. For this reason, it is important to test the packaging

under simulated use conditions to determine real-life effects on

the food product.

3

Residual studies estimate aworst-case dietary concentration

level, assuming 100%migration of any volatiles generated into

the food product. In residual studies, the level of each substance

ismeasured in the finished food-contact article. If nothing is

detected in the sample, then the validated detection limit can be

used to estimate the dietary concentration.

While there are specificmethods available formonitoring

volatile compounds in defined systems, method development

and validation often is the responsibility of the analyst.

American Society for Testing andMaterials (ASTM)Methods

4

F1308-98 and F1519-98 are qualitative and quantitative proce-

dures (respectively) formonitoring the volatiles generated by

microwave susceptor systems. Volatile extractables are defined

as substances released from the susceptor and detected in the

headspace. It is important to note that extractability does not

necessarilymeanmigration to the food.ASTMF1308-98 is a

quantitative procedure inwhich the packagingmaterials are

heated in a sealed systemwithin amicrowave prior to drawing

a headspace sample and injecting it into aGC/MS system.

ASTMF1519-98 is a qualitative procedure for identifying the

volatiles generated during simulated use conditions. This proce-

dure uses a purge and trap apparatus to collect and concentrate

the volatile compounds. Thesemethodswere used to develop

the general procedure for testing volatiles in food contact pack-

aging as described in this application note.

Experimental Conditions

To develop a general method formonitoring volatiles in food

contact packaging, we created a target list based on compounds

that have been detected in processed packagingmaterials. The

use of amass spectral detector will enable the identification of

other volatiles generated.We selected a low-bleed, Rtx

®

-5MS

capillary column to allow analysis of thewidest range of com-

pounds. Initial separation parameterswere entered into a com-

putermodeling program, which optimizes the separation based

on the column geometry, the oven temperature program, and the

linear velocity (Table I, on the back page).

An internal standard (IS) solution of 4-butanonewas prepared

by diluting 300mLof 4-heptanone to 1 liter with purifiedwater.

The final concentration of the IS solutionwas 245mg/mL. The

high standard solutionwasmade by adding 50mLof each com-

ponent to 475mLof the IS solution, and diluting to 500mL

using the IS solution.Medium and low standard solutionswere

prepared using 25mLand 10mLof each component, respective-

ly, and diluting each to 500mLusing the IS solution. The chro-

matogram of a 12-component high standard solution is shown

in Figure 1. Blank runswere performed before each standard

and sample by analyzing a 100mLaliquot of the IS solution.

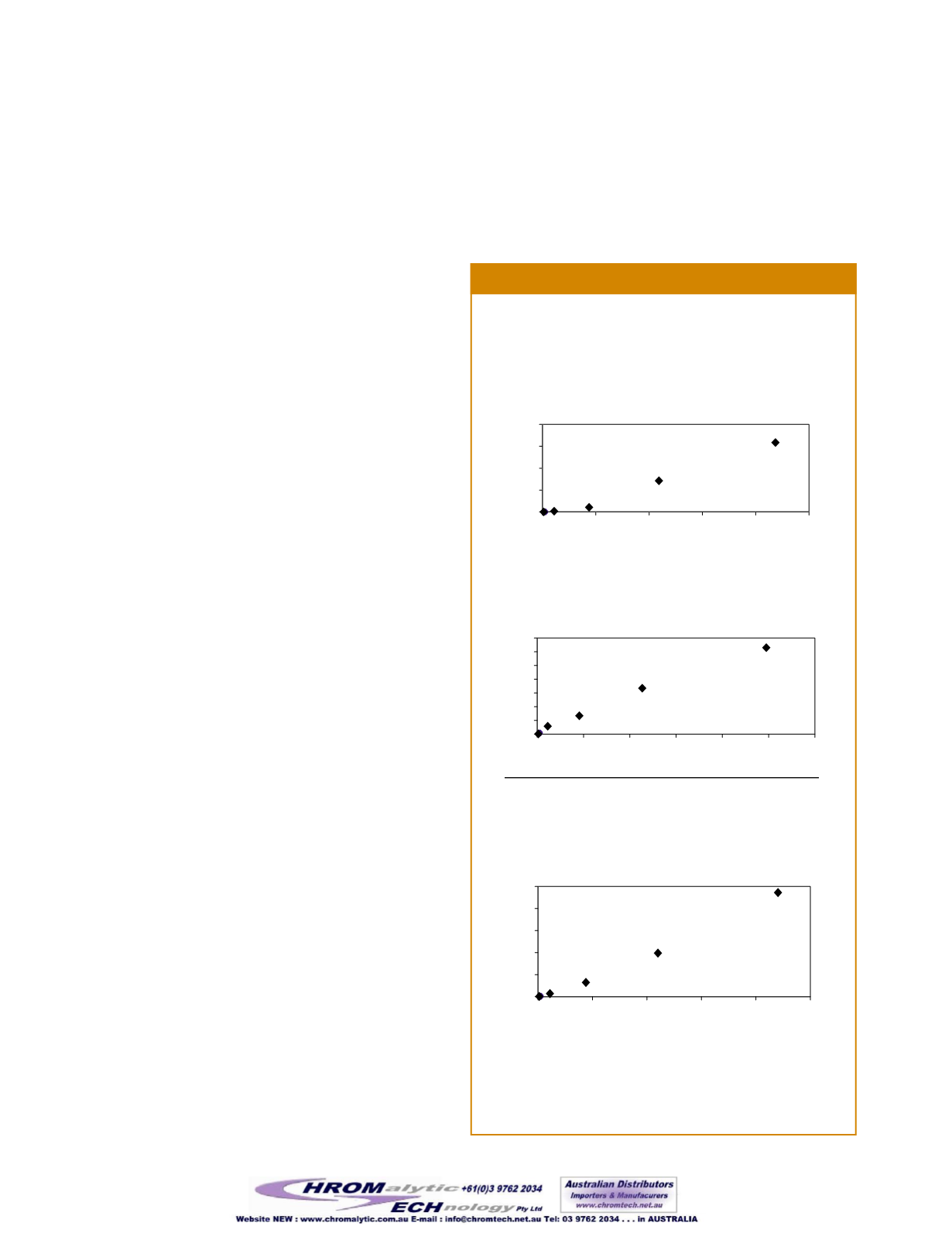

In order to determine the linearity of three packaging volatiles

using this procedure, a series of standard solutions containing

Figure 2

The Rtx

®

-5MS column exhibits good linearity for 3 volatile com-

pounds that may be present in food packaging.

Tested over an approximate concentration range of 0–10 µg/in

2

for each component. R

2

= 0.992 (THF), 0.985 (benzene),

and 0.994 (styrene).

THF, benzene, styrene, and 4-heptanone (IS) were prepared and

analyzed under the optimized parameters given inTable I. The

standard preparation procedure described above alsowas used

to prepare the linearity solutions. The approximate concentra-

tion range for each compoundwas 0-10µg/in

2

. The linearity

plots for three of the components are shown in Figure 2, with

the relative peak area (peak area for the volatile/peak area for

the IS) plotted vs. the concentration in µg/in

2

. To further increase

the sensitivity of this analysis, theMS can be operated in select-

ed ionmode.

THFLinearityPlot

0

1

2

3

4

5

0

2

4

6

8

10

Concentration, µg/in

2

BenzeneLinearityPlot

0

1

2

3

4

0

2

4

6

8

10

Concentration, µg/in

2

StyreneLinearityPlot

0

1

2

3

4

5

6

7

0

2

4

6

8

10

12

Concentration, µg/in

2

Relative PeakArea

Relative PeakArea

Relative PeakArea