food& flavors

Applications

note

Restek Corporation • (800) 356-1688 • (814) 353-1300 •

#59348

food& flavors

MonitoringVolatileCompounds in FoodContact PackagingUsingPurge and

TrapGC/MS and anRtx

®

-5MSCapillaryColumn

Introduction

Food packaging can be designed from awide variety ofmateri-

als, in a range of sizes, shapes, and colors.With the increasing

popularity of convenience foods, meals often are preparedwith-

in the packagingmaterials. Packagesmight be placed in an

oven, amicrowave, orwithin a pot of boilingwater. For

microwavable packaging, foodmanufacturers prefer to use

cheap, safe, and, to some extent, recyclablematerials.

1

Microwave susceptor systems can be used to heat foodsmore

rapidly, aswell as to crisp and brown the foods they contact.

Susceptors aremade by laminatingmetallized polyester to paper-

board. For dual-ovenable applications, ovenable paperboard and

CPET (crystalline polyethylene terephthalate) can be used.

For all packagingmaterials, there is the potential to generate

undesirable volatile compoundswhen used at elevated tempera-

tures. Inmany instances, these compounds canmigrate into or

out of packagingmaterials.When flavor compoundsmigrate

out of a food or beverage into the packaging, scalping occurs.

This can result in a loss of flavor or a change to the flavor pro-

file. Ofmore concern from a food safety perspective are com-

pounds that have the potential tomigrate out of the packaging

material into the food product.

TheUSFood&DrugAdministration (FDA) has stated,

“Anyonemanufacturing food contact articles for use in the

home or in food service establishments shouldmake sure that

nothing from the articles imparts flavor, color, odor, toxicity, or

other undesirable characteristics to food, thereby rendering the

food adulterated.”

2

In order to test the safety of food contact

materials, packaging should be tested under simulated use con-

ditions. Purge and trap gas chromatography/mass spectrometry

(GC/MS) is a powerful tool formonitoring the volatile com-

pounds that are generated during heating of packagingmateri-

als. This analysis technique can be applied to awide range of

packagingmaterials that are heated during food preparation.

Indirect food additives are defined as substances that are used

in the processing, packaging, holding, and/or transporting of

food, have no functional effect on the food, but whichmight

become a component of the food.

1

Plastic packaging in general

ismade of non-volatile, highmolecular weight polymers, but

volatile compounds often are added to improve the functional

properties of the polymers. Such volatile compounds include

plasticizers, antioxidants, UVblockers, and lubricants. The

packaging inks and dyes used to create the label graphics can

contain residual solvents, whichmay be toxic at certain concen-

trations. In addition, thermal breakdown of a polymermight

occur in the inner ply of a boil-in bag or oven bag, thereby

forming volatile species. Compounds such as benzene, styrene,

and tetrahydrofuran (THF) have been shown to cause adverse

affects on humans, and food contact materials need to be tested

to ensure these volatiles are not present at significant levels.

In addition to the safety concerns, volatile compoundsmigrat-

ing into foodmaterials can change the flavor profile of the food

product. For example, polystyrene is used to packagemany

aqueous-based, fatty or dry foods. Trace levels of styrene pres-

ent in the polystyrene can impart a “plastic” taste to the food

product.

In 21CFR 170.39, theUSFDAoutlines the data needed to

request an exemption from regulation as a food additive.

Information needed includes the use conditions, time/tempera-

ture, food type, andwhether thematerial is used once ormulti-

ple times. Other required information includes a detailed

description of the analytical method and themethod validation

data, including the detection limit.

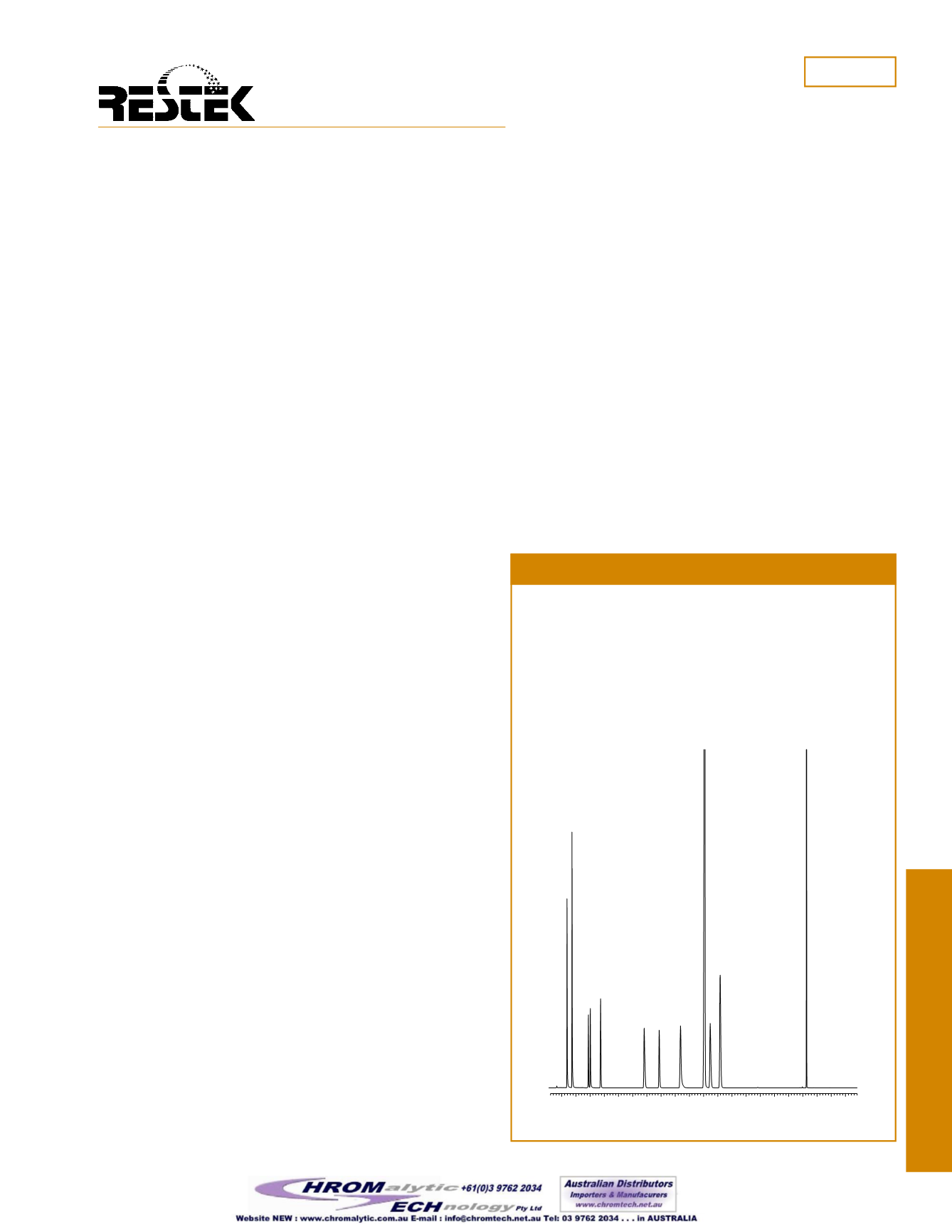

Figure 1

1. isopropanol

2. methylene chloride

3. 2-methyl-1-propanol

4. tetrahydrofuran

5. benzene

6. toluene

7. hexanal

8. furfural

9. 4-heptanone (IS)

10. butyl ether

11. styrene

12. dodecane

The Rtx

®

-5MS column exhibits good peak shape and high

sensitivity for 12 volatile compounds that may

be present in food packaging.

1

2

9

3

4

5

6 7 8 10

11

12

2 4 6 8 10 12 14 16 18 20

GC_FF00457

See Table I, back page,

for analysis conditions.