70

TUBING

Fluoropolymer Tubing

UpchurchScientific

®

TubingODSizes

Pleaseuse this tableasa reference tool tohelpquickly locatewithin

this chapter theappropriateOD size tubing for your application.

Size

TubingOD

Page(s)

360µm

67, 68, 72

510µm

65, 67

1/32”

65, 67, 68, 71

1/16”

63, 65, 66, 68, 69, 71, 72, 73, 77

1/8”

65, 66, 69, 71, 72, 73

3/16”

71, 72

1/4”

71, 72, 73

Size

TubingOD

Page(s)

5/16”

71

1mm

71

1.8mm

66

2mm

66, 71

3mm

71

4mm

71

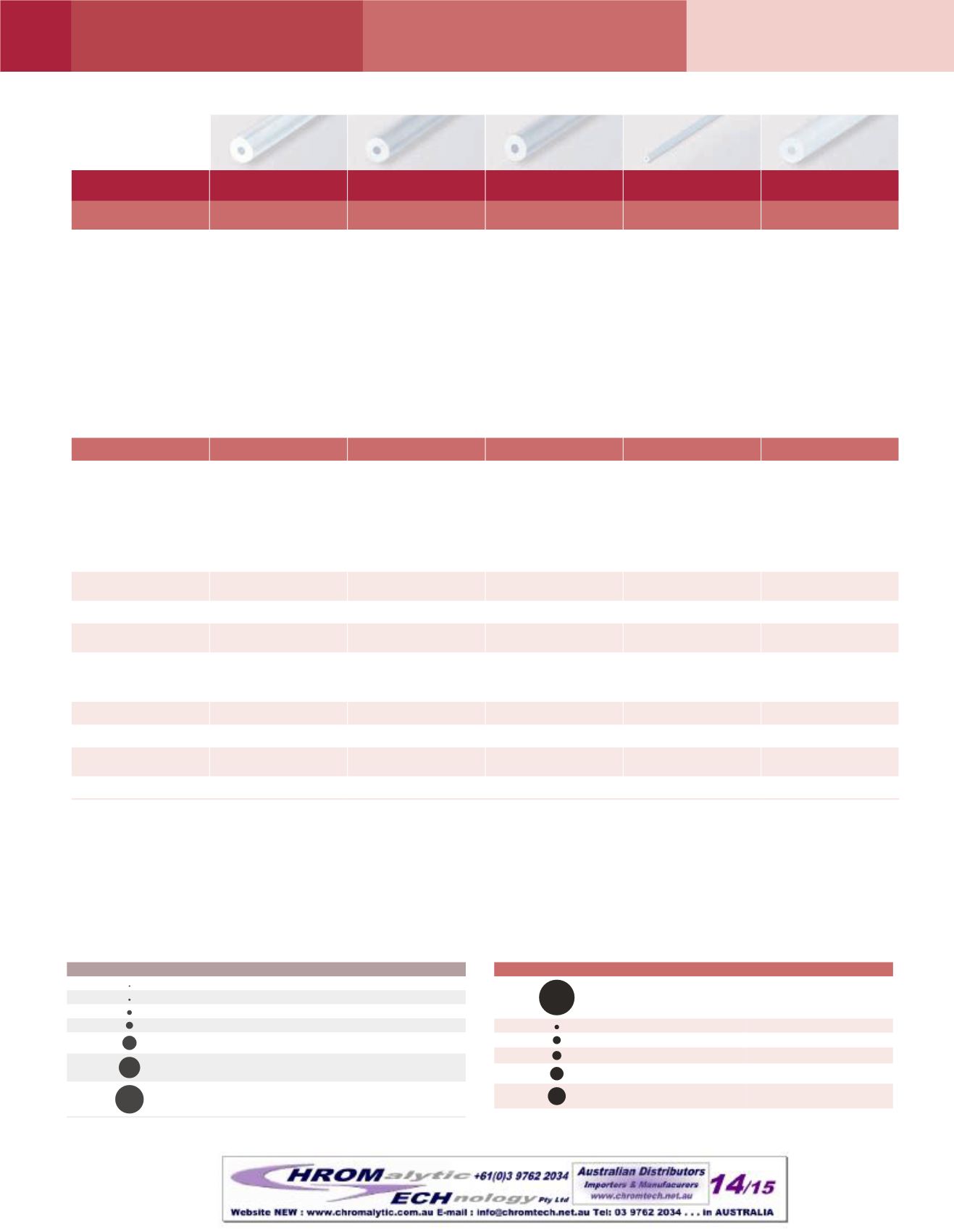

TUBING

D

u

P

ont

®

FEP

D

u

P

ont

PFA

D

u

P

ont

HIGH

PURITYPFA

360µmD

u

P

ont

HIGHPURITYPFA

ETFE

Page

71

72

72

72

73

Description

FEP tubing isagreat

alternative to traditional PTFE

tubing, desirable foruse

because it ischemically inert to

most solvents, easy tocut, and

translucent foreasymonitoring

of solutionspassing through.

•Great forgeneral, low

pressureapplications

•Many sizesavailable

inmultiplecolors for

easy identification

•Tightmanufacturing

tolerances toensure

product consistency

Offersexcellent chemical

compatibility, plusdue to its

inner surface smoothness,

PFA tubing tends tobemore

translucent thanPTFE tubing.

•Offershigherpurity

andenhanced translucence

whencomparedwithother

fluoropolymer tubes

•Great formorecritical, low

pressureapplications

Thispolymer tubing is

manufactured fromapremium

gradeof PFA—oneof

themost contaminant-free

polymerson themarket.

•Offerschemical stability,

mechanical strength, and

purity for applications such

asmedical, diagnostic,

pharmaceutical,

biotechnology, and

semiconductor

•Excellent replacement for

PTFEwheregaspermeability

and surface textureare issues

•Clarityof tubingmakes

PFAanexcellent choice for

monitoringfluidmovement

This tubingoffersexcellent

chemical compatibility,

transparency, very low

contaminant levelsand

isavailable in themost

commonly-usedoutside

diameter for capillary

tubingapplications.

•Replacement for capillary

tubing in lowpressure

applicationswhereexcellent

chemical compatibility

is required

•Tubing sleevesavailable for

capillary tubingconnections

ETFE ischemically inert and

more suitable forhigher

pressureapplications (when

usingaqueousmobilephases)

thanPTFE, FEP, andPFA.

Additionally, becauseETFE is

more rigid thanPTFE, FEP, and

PFA, this tubingbetter resists

innerdiameter collapse.

•Excellent solvent resistance

•Moredurableand less

gaspermeable than

PTFE, FEP, andPFA

•Operating temperatures

up to80 °C

Specifications

OD

(outsidediameter)

1/32" (785µm),

0.040" (1.0mm),

1/16" (1.55mm),

0.080" (2.0mm),

0.118"(3.0mm),

1/8" (3.2mm),

0.157"(4.0mm),

3/16" (4.8mm),

1/4" (6.35mm),

5/16" (7.94mm)

1/16" (1.55mm),

1/8" (3.2mm)

1/16" (1.55mm),

1/8" (3.2mm),

3/16" (4.8mm),

1/4" (6.35mm)

0.0145" (360µm)

1/16" (1.6mm),

1/8" (3.2mm),

1/4" (6.35mm)

ID

(insidediameter)

0.003" (0.075mm) –

0.250" (6.35mm)

0.020" (0.50mm)–

0.062" (1.55mm)

0.020" (0.50mm)–

0.188" (4.80mm)

0.002" (50µm)–

0.006" (150µm)

0.010" (0.25mm)–

0.188" (4.80mm)

OperatingTemp

-51 to50 °C

-51 to80 °C

-51 to80 °C

-51 to80 °C

-51 to80 °C

PressureRating

2,500–4,000psi

(172 - 276bar)

500–2,000psi

(34–138bar)

250–2,000psi

(17–138bar)

1,750–3,500psi

(121–241bar)

250–4,000psi

(17–276bar)

Typical Tolerances

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm) for

1/8"OD tubing

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm) for

1/8"OD tubing

±0.001" (25µm) for

1/16"OD tubing

±0.0005" (12.5µm)

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm) for

1/8"OD tubing

Refractive Index (Clarity)

1.338

1.34

1.34

1.34

1.4

pHRange

0–14

0–14

0–14

0–14

0–14

SterilizationTechniques

Ethyleneoxide; thermal

Ethyleneoxide; thermal

Gamma irradiation; ethylene

oxide; thermal

Gamma irradiation; ethylene

oxide; thermal

Ethyleneoxide

Autoclavable?

Y

Y

Y

Y

Y