64

TUBING

StainlessSteelTubing

XX

Precut 316 stainless steel*

XX

AvailableODs include 0.020”, 1/32”, 1/16”, and 1/8”

XX

Color-codedbanding for easy identificationof the inner diameter

IDEXHealth & Science seamless, precut stainless steel tubing is

designed tomeet the exacting requirements of today’s analyses.

We machine cut and polish each end, deburr the inside and

outsideedges, andpassivate the tubing (please see thepassivation

informationon thispage).Finally,weflush reagent-grade isopropanol

througheachpiece.

Our thoroughpreparationandcleaningprocedureguarantees tubing

that is truly ready-to-use, with flat, burr-freeends and a clean finish.

Thiscare is important inachievingzero-dead-volumeconnectionsand

goodchromatographic results.

Weofferavarietyofprecut lengthsaswellas longer lengths (5’and25’)

of some sizes.Cutting the tubingdisturbsand roughens the tubing’s

end surface, sowe recommend usingour precut tubingwhenever

possible. If you need to cut tubing to custom lengths, we suggest

you thenpassivate the tubing. For adescriptionof acoldpassivation

process, pleasecontact IDEXHealth&Scienceor visit ourwebsiteat

search for “stainless steel tubing.”

*Exceptour 0.020”ODStainlessSteel Tubing,which ismanufactured from304 series stainless steel.

NOTE

PEEKpolymer tubingcanbeused to replace stainless steel tubing

inmost liquidanalytical systems.Unlike stainless steel tubing, PEEK

tubing isbiocompatible, flexible, andcaneasilybecut todesired

lengths. Seepages66–68.

All StainlessSteel tubing longer than1m is coiled.

Stainless Steel TubingPassivation

Stainless steel isnaturally self-passivating, forminganoxidized layer

onnewlycreated surfaces. IDEXHealth&Science takesextra steps

toensure thechemical resistanceof our stainless steel tubingby

manuallypassivatingbeforeandafter the tubing is cut into specified

lengths (except ina fewcaseswhere size isprohibitive). In theprecut

stage, the internalwall isacidpassivatedandflushed.After the tubing

is cut, deburredandpolished, it is completely submerged inanacid

passivationbathandagainflushedclean. The tablebelow summarizes

themanual passivation stepsperformed for each sizeof our stainless

steel tubing:

TubingOD Precut Passivation

Postcut Passivation

0.020”

All

All

1/32”

All

All

1/16”

All

All, ex. 25’ lengths

1/8”

None

All, ex. 3&5m lengths

APPLICATIONNOTE

XX

Our 1/32”OD tubing is designed for enhanced flexibility inhigh

pressure applications.

XX

Standard 1/16” and 1/8”OD stainless steel tubing is suited for

most analytical applications.

RELATEDPRODUCTS

XX

Our 0.020”OD tubing is the sizeof choice for theRheodyne

®

Model 8125Micro-Scale Injector Valve (page 132).

XX

PEEKpolymer tubing is available in all of these sizes, listedon

pages 66–67.

SPECIFICATIONS&DETAILS

XX

MaximumRecommendedOperatingTemperature: 750 °F (399 °C).

XX

Rockwell Hardness (B):Maximumof 95.

XX

MeetsASTMA269 andA213.

TubingOD

ODTolerance

Tubing ID

IDTolerance

0.020”

±0.0005” (12.5µm)

All

±0.0005” (12.5µm)

1/32”

+0.002”/-0.000”

(+50µm/-0µm)

All, except 0.004”

(0.10mm)

+0.000”/-0.002”

(+0µm/-50µm)

1/32”

+0.002”/-0.000”

(+50µm/-0µm)

0.004” (0.10mm)

+0.002”/-0.000”

(+50µm/-0µm)

1/16”

+0.002”/-0.000”

(+50µm/-0µm)

All

±0.001” (25µm)

1/8”

±0.003” (75µm)

All

±0.003” (75µm)

HighPressureTubing

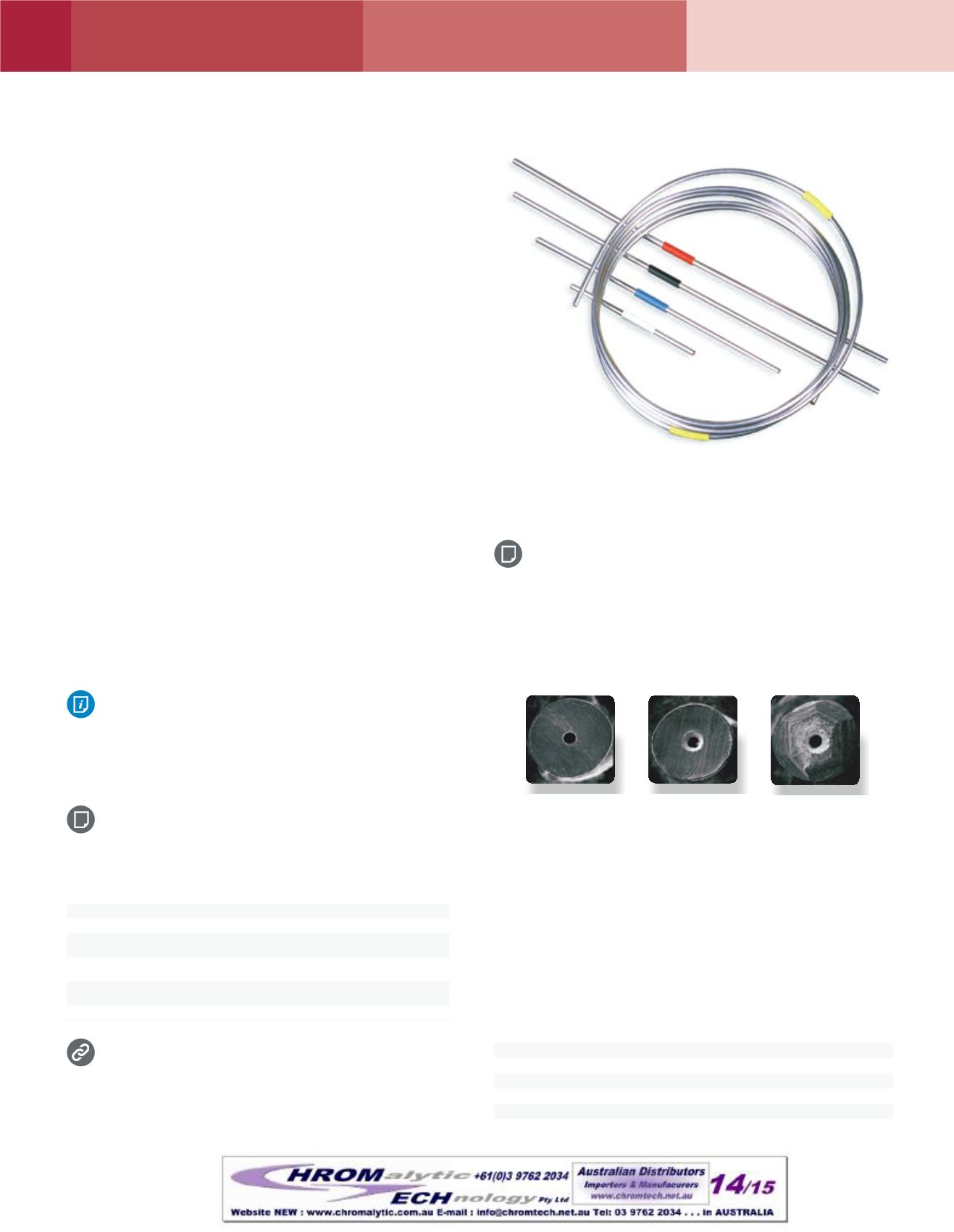

Tubing cut

bya commercially

available

tubing cutter

File cut tubing

Precut tubing

TheBeautyof Precut Tubing