62

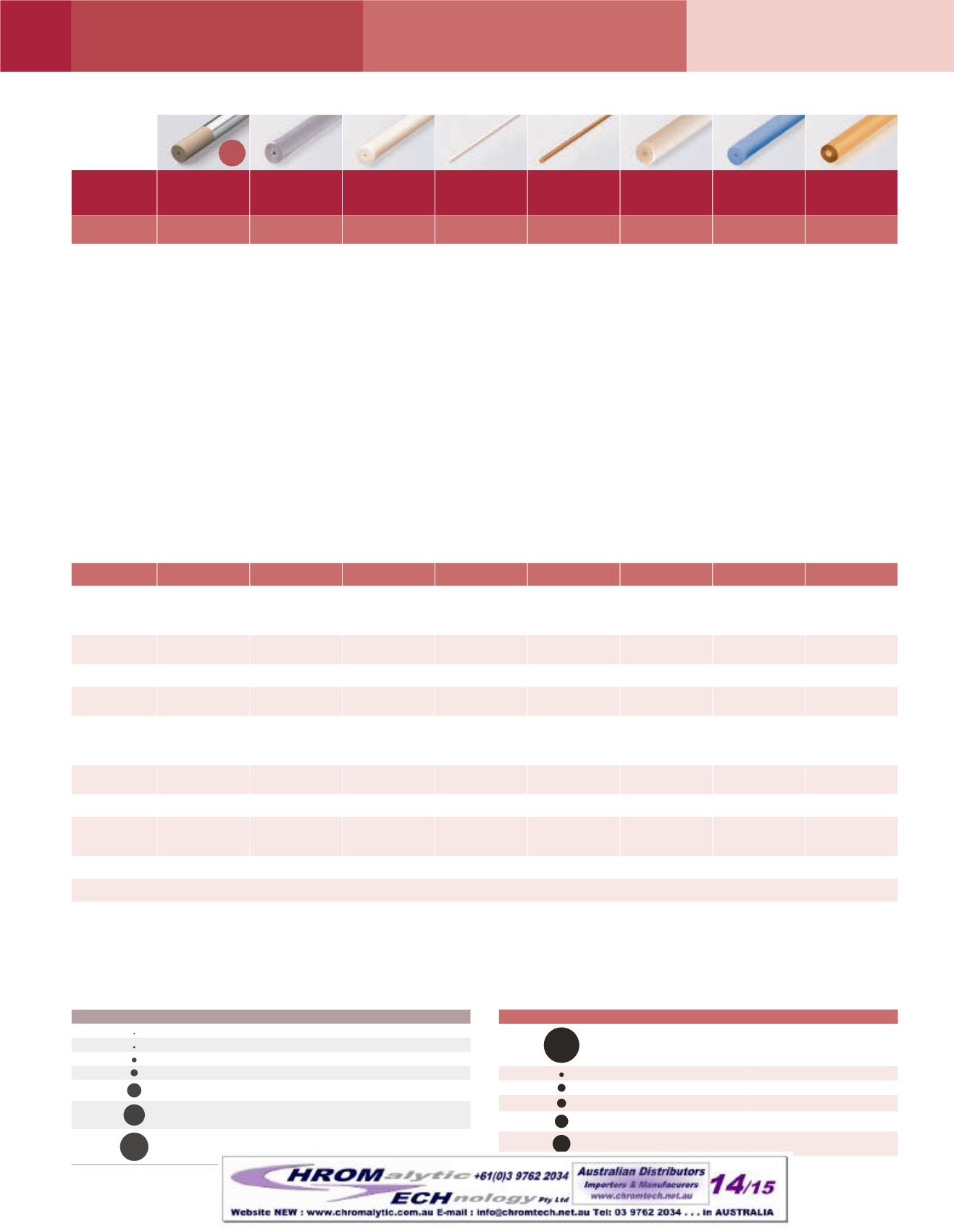

TUBING

TUBING

PEEK-LINED

STAINLESS

STEEL (PLS)

STAINLESS

STEEL

PEEK

CAPILLARY

PEEK

FUSEDSILICA PEEKsil

™

SPIRAL-LINK

™

RADEL

®

Page

63

64

66

67

67

68

69

69

Description

Biocompatible,

chemically inert to

most commonly-

used solvents, PLS

tubingoffersa

PEEK inner layer

which servesas

thefluidpathway,

jacketedby

stainless steel.

• Ideal forbio-

inertUHPLC

applications

•Canbebent into

various shapes

without affecting

performance

Seamless, pre-cut

316 stainless steel

tubingmeets

theexacting

requirementsof

today’sanalyses.

Thorough

preparation

guarantees that

the tubing is truly

ready-to-use,with

flat-burr-freeends

andacleanfinish.

•Wide selection

ofoutsideand

insidediameters

and lengths

•Pre-cut toensure

burr-free, flat

connections

•Many sizes

featurea

color-coded

band foreasy ID

identification

Biocompatible,

chemically inert to

most commonly

used solvents, PEEK

tubing isflexible,

offersavery smooth

internal surface, and

canbeeasilycut to

desired lengths.

•Great alternative

for stainless

steel tubing in

highpressure

applications

•Many sizes

available incolor

scheme tohelp

identify ID

All thebenefits

of larger sized

PEEK tubing,

while serving

asanexcellent

alternative tomore

traditional fused

silicaand stainless

steel capillary

tubing.Capillary

PEEK tubing is

available inawide

rangeofmicroand

nano-scale inner

diameters.

•Available in

commoncapillary

tubing sizeswith

tight tolerances

onODand ID

•Tubing sleeves

available for

capillary tubing

connections

Becauseof the

tight tolerances

of fused silica’s

innerdiameters,

this tubing isused

formicro-scale

analyses suchas

microandnano-

HPLCandcapillary

electrophoresis.

•Most commonly

usedODand ID

sizesavailable

•Highquality,

polyimide-clad

fused silica

•Offered in

convenient, two

meter lengths

PEEKsil is

mechanically strong

andhas ideal

characteristics for

sealingwithmetal

orpolymer fittings.

•Comprisedof

highquality fused

silica sheathedby

PEEK tubing

•Excellent

chemical

compatibility

•Very tight

manufacturing

tolerances

•Good

replacement

for stainless steel,

PEEK, or standard

fused silica

ThePEEKSpiral

Linkcoilsexpand

andcontract,

allowingyou to

easilymoveyour

systemcomponents

orevenmake

equipment repairs

wheneverneeded,

without thehassle

ofbreaking

connections.

•Available in

several specific

volumes

• Includes two

SealTight

™

fittings

Amechanically

strongand

chemically resistant

material,much

likePEEKpolymer,

Radel is frequently

used inmedical

applicationswhere

repeatedautoclave

sterilization is

performed (tests

showproduct

stabilityafter1,000

cycles).Radel tubing

isalso transparent,

allowing technicians

tovisuallymonitor

flow through their

instrument.Readily

wettedsurfaceshelp

keepairbubbles

fromaccumulating

on inner surfaces

aswell.

•Withstandsup to

12,500psi

(862bar)

•Transparent and

autoclavable

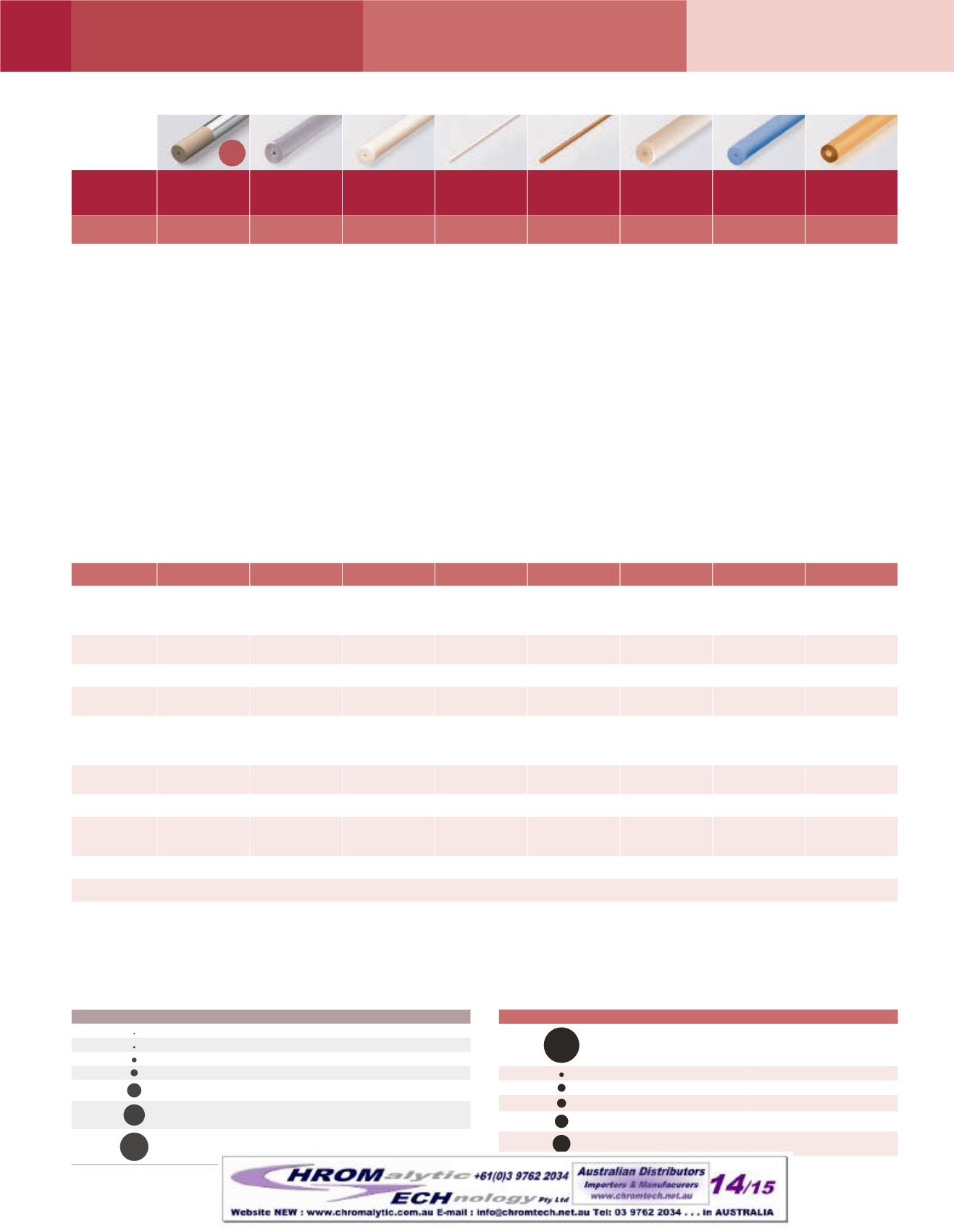

Specifications

OD

(outside

diameter)

1/16” (1.6mm)

0.020" (510µm),

1/32" (785µm),

1/16" (1.55mm),

1/8" (3.2mm)

1/16" (1.55mm),

0.071" (1.8mm),

0.079” (2.0mm),

1/8" (3.2mm)

0.0145" (360µm),

1/32" (785µm),

0.020” (0.5mm)

0.0145" (360µm)

0.0145" (360µm),

1/32" (785µm),

1/16" (1.55mm)

1/16" (1.55mm)

1/16" (1.55mm),

1/8" (3.2mm)

ID

(insidediameter)

0.001” (25µm)–

0.010” (254µm)

0.004" (100µm)–

0.080" (2.0mm)

0.001" (25µm)–

0.080" (2.0mm)

0.001" (25µm)–

0.020" (0.50mm)

0.0008" (20µm)–

0.006" (150µm)

0.001" (25µm)–

0.012" (300µm)

0.005" (125µm)–

0.030" (0.75mm)

0.010" (0.25mm)–

0.062" (1.55mm)

OperatingTemp

-51 to100 ºC

-51 to289 ºC

-51 to100 °C

-51 to100 °C

-51 to100 °C

-51 to100 °C

-51 to100 °C

-51 to100 °C

PressureRating

17,400psi

(1,200bar)

N/A*

500–10,000psi

(34–690bar)

2,000–5,000psi

(138–345bar)

N/A*

10,000psi (690bar)

7,000psi (484bar)

5,500–12,500psi

(379–862bar)

Typical

Tolerances

±5 to15µm

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm)

for 1/8"OD tubing

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm)

for 1/8"OD tubing

±0.0005" (12.5µm)

±0.0004" (10µm)

±0.0004" (10µm)

±0.001" (25µm)

for1/16"OD tubing

±0.001" (25µm) for

1/16"OD tubing,

±0.003" (75µm)

for 1/8"OD tubing

Refractive Index

(Clarity)

Opaque

Opaque

Opaque

Opaque

1.78

Opaque

Opaque

1.672

pHRange

0–14

1–14

0–14

0–14

0–10

0–10

0–14

1–14

Sterilization

Techniques

Gamma irradiation;

ethyleneoxide;

thermal

Gamma irradiation;

ethyleneoxide;

thermal

Gamma irradiation;

ethyleneoxide;

thermal

Gamma irradiation;

ethyleneoxide;

thermal

Ethyleneoxide;

thermal

Ethyleneoxide;

thermal

Gamma irradiation;

ethyleneoxide;

thermal

Thermal, gamma

irradiation

Autoclavable?

Y

Y

Y

Y

Y

Y

Y

Y

*Themanufacturerof this tubingormaterial doesnotpublish this specification.

Size

TubingOD

Page(s)

360µm

67, 68, 72

510µm

65, 67

1/32”

65, 67, 68, 71

1/16”

63, 65, 66, 68, 69, 71, 72, 73, 77

1/8”

65, 66, 69, 71, 72, 73

3/16”

71, 72

1/4”

71, 72, 73

Size

TubingOD

Page(s)

5/16”

71

1mm

71

1.8mm

66

2mm

66, 71

3mm

71

4mm

71

UpchurchScientific

®

TubingODSizes

Pleaseuse this tableasa reference tool tohelpquickly locatewithin this

chapter theappropriateOD size tubing for your application.

HighPressureTubing

NEW!