I

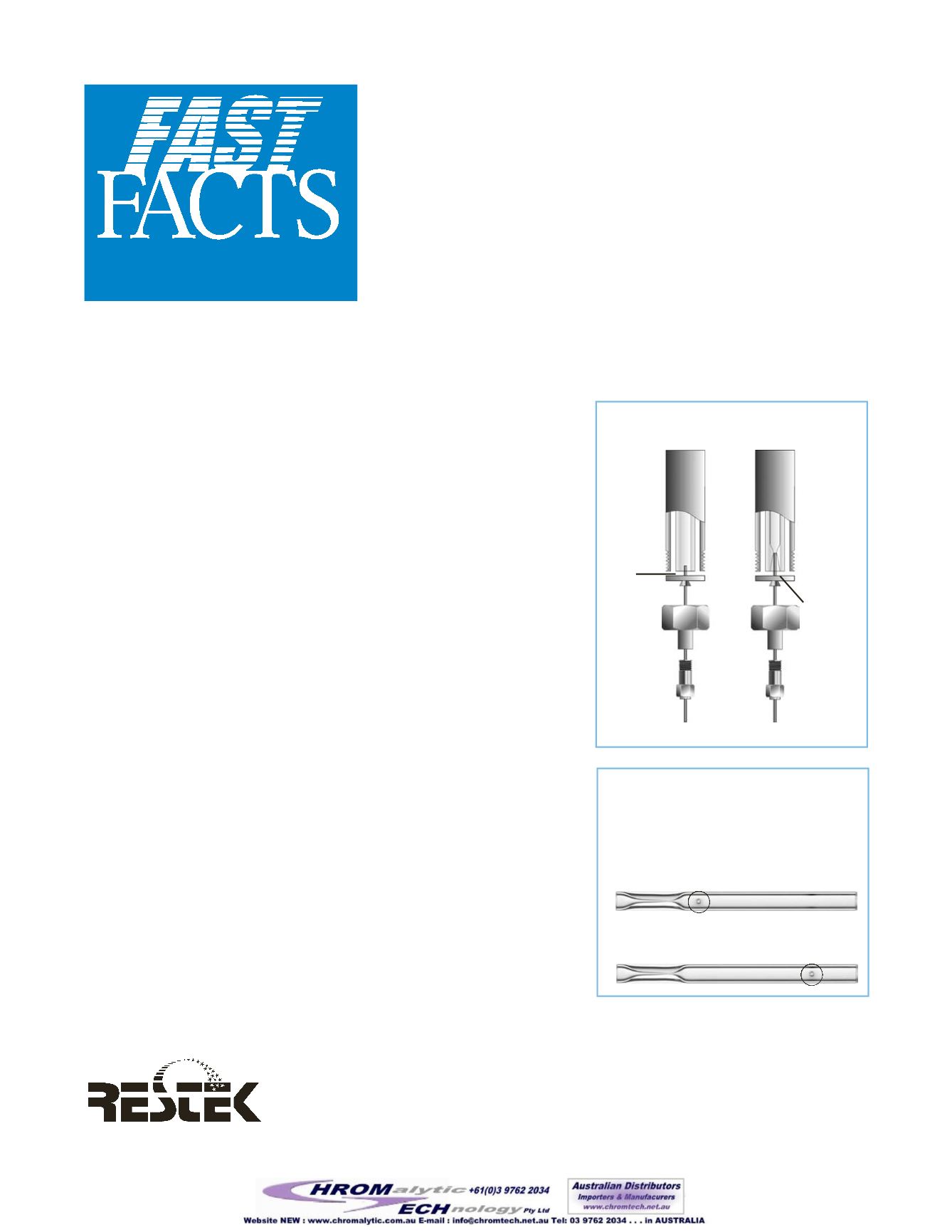

n sample injections into a hot splitless injectionport liner, a typical 1µL sample expands to a volume of hundreds

ofmicroliters.

1

The sample solvent vapor, and the analytes, fill the entire injector system. During sample expan-

sion, analytemolecules come in contactwithhot, active surfaces outside the injectionport liner, andoccupy the

deadvolume at the bottomof the injectionport, below the inlet endof the

column (Figure 1). In splitless injectionmode, there is very little carrier

gas flow in this area to carry the analytes backup to the column inlet.

This situation ismost noticeablewith active compounds that degrade

when they come in contactwith active surfaces; recoveries canbe signifi-

cantly reduced. In addition, late-eluting compounds that donot readily

vaporize are affectedby injectionport discrimination.

The innovative geometry of aDrilledUniliner

®

inlet liner minimizes

active sites in the sample pathway, and reduces injection port discrimi-

nation. The analytical column connects to the bottom of aDrilled

Uniliner

®

inlet liner via a Press-Tight

®

seal (Figure 1), eliminating sam-

ple contact with any part of the injector below the column inlet.

Recoveries of active analytes are significantly improved.

2

Additionally,

the hole in the side of the liner allows the injector to be operated in tra-

ditional split/splitlessmode.

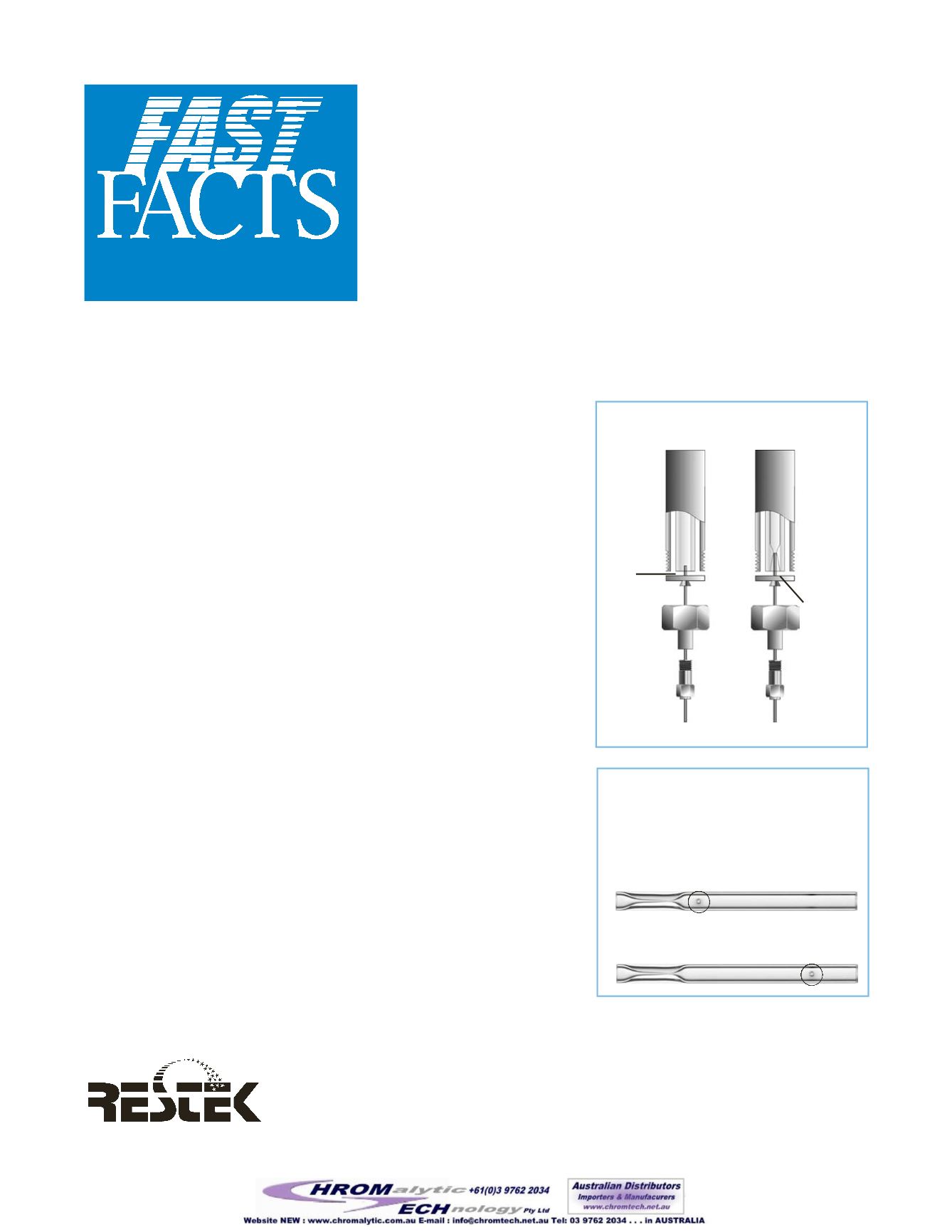

Restek offersDrilledUniliner

®

inlet liners in two configurations (Figure

2). The liner to use depends on the analysis, and how closely the early-

eluting compounds elute to the solvent peak.

In flash on-column injections, all of the solvent is transferred from the

injector to the column, producing a substantial solvent peak tail.

Splitless injection eliminates the solvent tail, because the injector goes

into the splitmode after the compounds of interest are transferred to the

column, and all solvent remaining in the injection port is flushed out

through the purge vent. The solvent peak ends abruptly, as shown in

Figure 3a. Elimination of the solvent peak tail is an advantage to using

the splitless injection techniquewhen analyzing compounds that elute

close to the solvent.

ADrilledUniliner

®

inlet liner produces a distinctly different solvent peak

shape than the single gooseneck splitless liner, as shown inFigure 3. Themost noticeable difference is the peak

width; the peak is considerably narrower than the peak from the single gooseneck liner. The position of the hole in

theDrilledUniliner

®

also affects solvent peak shape.ADrilledUniliner

®

with the

hole near the bottom produces a sharply ending solvent peak, similar to that from a

single gooseneck liner (Figure 3b). This liner is a direct replacement for a splitless

liner, and should be usedwhen analytes elute closely behind the solvent.

At-a-Glance Product

Information fromRestek

800-356-1688

●

814-353-1300

MinimizeAdsorptionofActive

Analytes,UsingaDrilled

Uniliner

®

GC InletLiner

TwoConfigurations, toMatch

ChromatographicConditions

Analytes

contact hot

surface and

dead volume

at base of

splitless

liner

Figure 1

—

Inlet liner geometry affects

analyte recovery.

Drilled

Uniliner

®

inlet liner

efficiently

transfers

sample onto

column

Use hole near top configuration if analytes elute later than

the solvent peak, or when the sample solvent iswater

Figure 2

—

DrilledUniliner

®

inlet liners

are available in two configurations. The hole

allows the injector to be operated in

split/splitlessmode.

Use hole near bottom configuration if analytes elute near

the solvent peak

Continued