V

0

~

Pharmaceutical

Successfully Implement the

Revised USP <467> Method

Continu ed from page5.

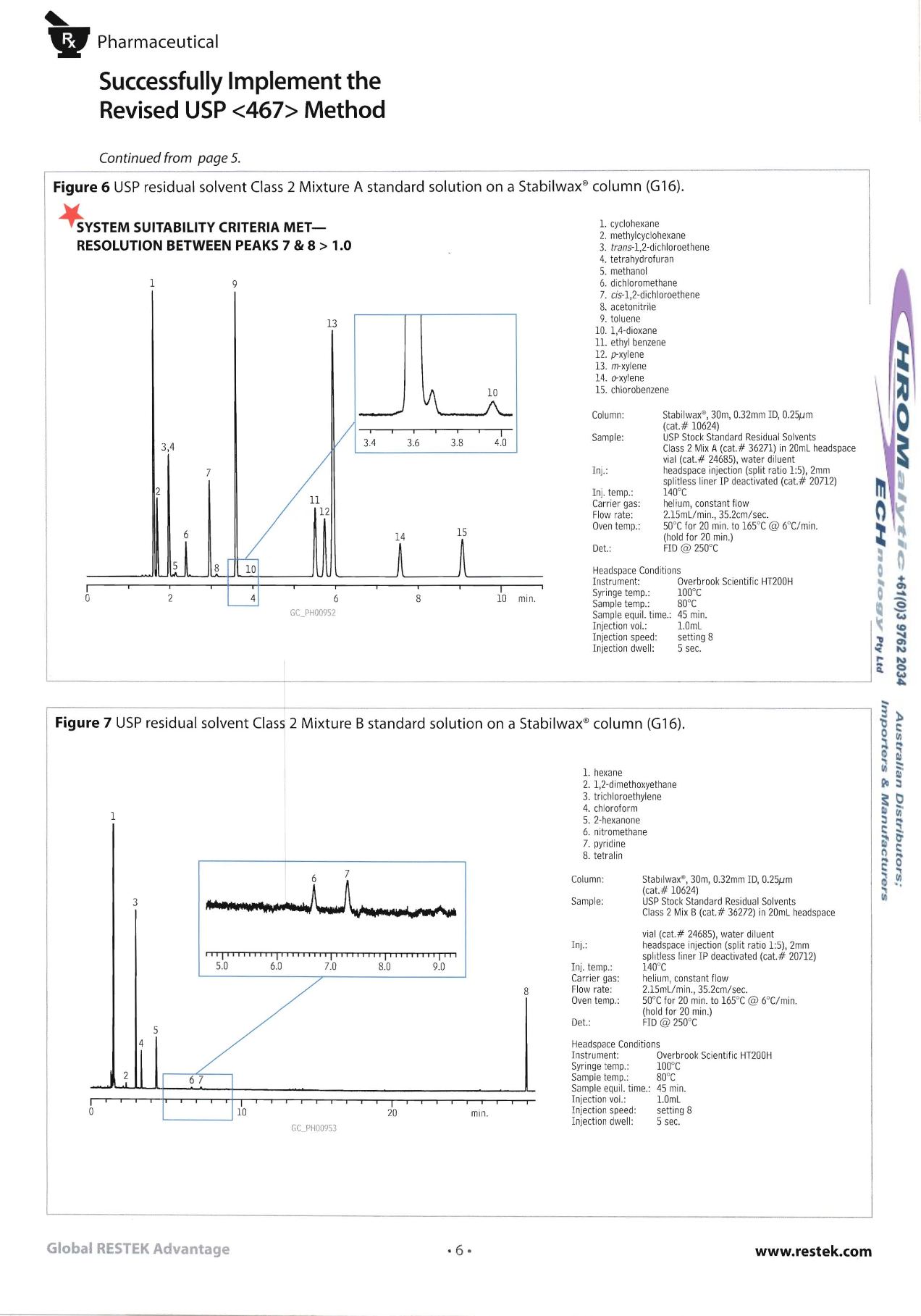

Figure 6

USP residual solvent Class 2 Mixtu re A standard solution on a Stabilwax" column (G16).

.-¥sYSTEM SUITABILITY CRITERIAMET-

1. cyclohexane

2. methylcyclohexane

RESOLUTIONBETWEEN PEAKS

7

&

8

>

1.0

3. trans-l, 2-dichloroethene

4. tetrahydrofuran

5. methanol

6. dichloromethane

7. cis-l,2-dichloroethene

8. acetonitrile

3,4

7

2

11

12

5 1

8

10

0

2

4

'-13

10

\;\

A, ,

,

,

i

i

i

,/

3.4

3.6

3.8

4.0

15

14

6

8

10

min.

9. toluene

10. lA-dioxane

11. ethyl benzene

12.p-xylene

13. m-xylene

14. o-xylene

15. chlorobenzene

Column:

Stabilwax",

30m, 0.32mm!D,

0.25j.1m

(cat.# 10624)

Sample:

USP Stock StandardResidualSolvents

Class 2 Mix

A

(cat.# 36271) in 20mLheadspace

vial (cat.# 24685), water diluent

Inj.:

headspace injection(split ratio 1:5), 2mm

splitless liner IPdeactivated (cat.# 20712)

Inj. temp.:

140°C

Carrier gas:

helium, constantflow

Flow rate:

2.lSmL/min., 3S.2cm/sec.

Oventemp.:

50°Cfor 20 min. to 165°C@ 6°C/min.

(hold for 20 min.)

Det.:

F!D @ 250°C

Headspace Conditions

Instrument:

OverbrookScientific HT200H

Syringetemp.:

100°C

Sample temp.:

80°C

Sample equil. time.: 45min.

Injectionvol.:

1.0mL

Injection speed:

setting 8

Injection dwell:

5 sec.

Figure 7

USP residual solvent Class 2 Mixture B standard solution on a Stabilwax" column (G16).

1. hexane

2. 1,2-dimethoxyethane

3. trichloroethylene

4. chloroform

5. 2-hexanone

6. nitromethane

7. pyridine

8. tetralin

6 7

Column:

Stabilwax",

30m, 0.32mm!D,

0.25j.1m

(cat.# 10624)

3

Sample:

USPStock Standard Residual Solvents

/lll'1~1.

Class 2 Mix

B

(cat.# 36272) in 20mL headspace

~~

vial (cat.# 24685), water diluent

Inj.:

headspace injection (split ratio 1:5), 2mm

sphtless linerIPdeactivated (cat.# 20712)

"'1""""'1""""'1" """'1""""'1'"

5.0

6.0

7.0

8.0

9.0

In]. temp.:

140°C

Carrier gas:

helium, constant flow

8

Flow rate:

2.15mL/ min., 35.2cm/ sec.

Oven temp.:

50°Cfor 20min. to 16SoC@ 6°C/min.

(hold for 20min.)

Det.:

F!D @ 250°C

5

4

II

Headspace Conditions

Instrument:

OverbrookScientific HT200H

Syringe temp.:

100°C

2

Sample temp.:

80°C

6 7

Sample equil. time.: 45 min.

Injectionvol.:

1.0mL

'0

Injection speed:

setting8

1

20

min.

Injection dwell:

5 sec.

GCPH00953

Global RESTEKAdvantage

· 6 ·

www.restek.comWebsite :

www.chromtech.net.auE-mail :

info@chromatech.net.auTelNo : 03 9762 2034 . . . in AUSTRALIA