Avoid Resampling Soil Vapors

Confirm Tracer Gas in the Field Using a Leak Detector

By Irene DeGraff, Air Monitoring Product Marketing Manager, Russell Pellegrino, Director of Technical

Services*, and Kelli Steindl, GC Accessories Product Marketing Manager

* Centek Laboratories, LLC

• Confirm system integrity before sample collection.

• Minimize resampling by detecting leaks prior to sampling.

• Eliminate costly and time-consuming lab analysis of tracer gas.

References

1. NewYork State Department of Health, October 2006, Guidance for Evaluating Soil Vapor Intrusion in the State of

NewYork,

http://www.nyhealth.gov/environmental/investigations/soil_gas/svi_guidance/docs/svi_main.pdf(accessed August 27, 2010).

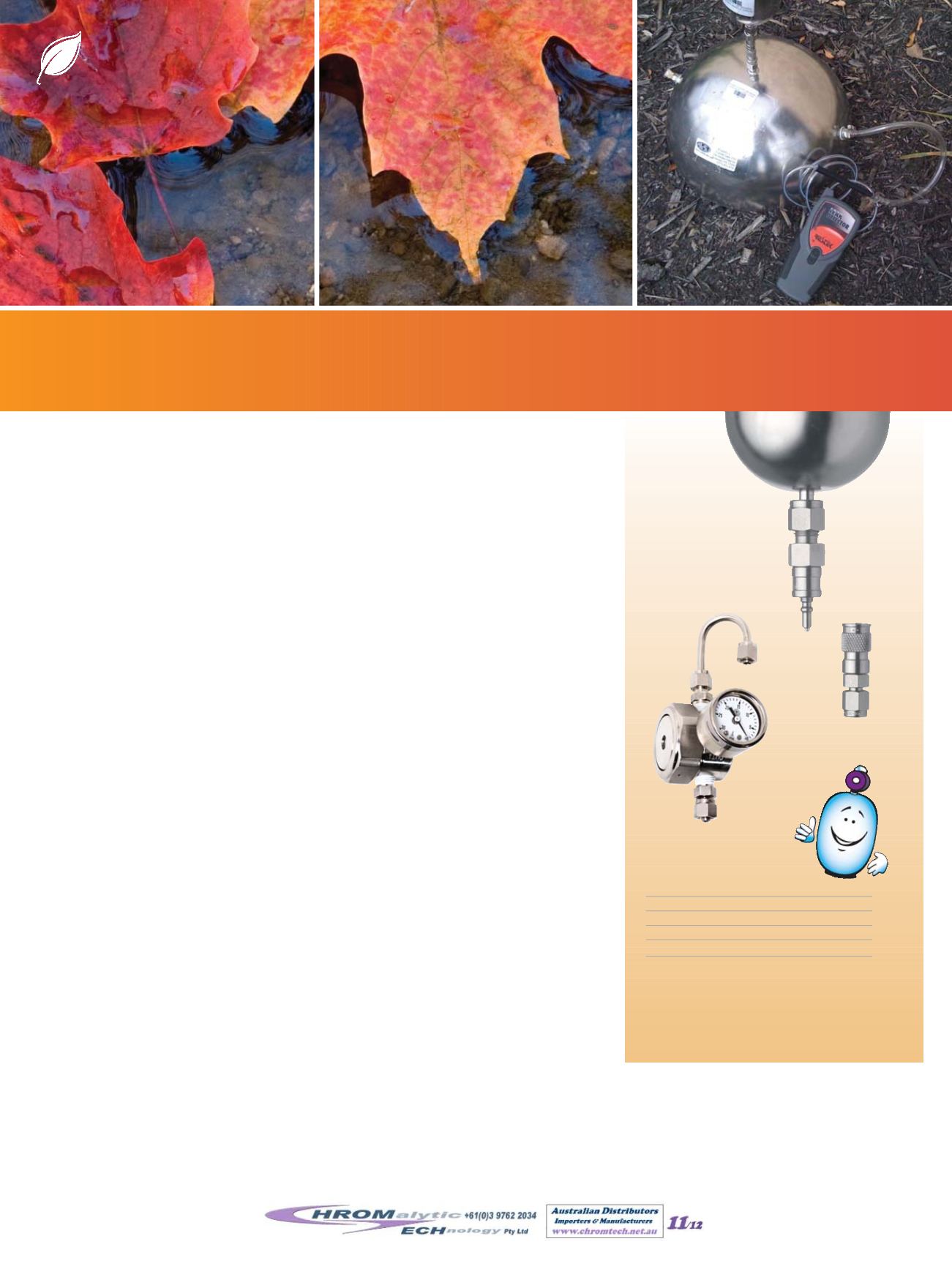

Restek

Mini-Cans

are ideal for both

tracer gas transfer

and introduction,

as well as sample

collection.

Mini-Can Options

Sizes

400cc, 1000cc

Valves

Quick connect, diaphragm

Interior Coating Electropolished, Siltek treated

Sample Inlets Area, personal

Flow ranges

0.5-15 sccm

For a full product listing,

visit

www.restek.com/airEnvironmental

10

www.restek.comVapor intrusion occurs when pollutants from contaminated soil or ground water migrate into

buildings and ambient air. Adverse health effects can result when vapors occur in high con-

centrations, or if toxic volatile organics are present. These compounds are monitored using a

variety of sampling procedures, including soil vapor, sub-slab, indoor, and ambient air test-

ing. Sample collection for volatile organic compounds (VOCs) typically is performed with an

air canister and passive sampling kit according to EPA Method TO-15 or a similar method.

Costly Detection in Lab Doesn’t Prevent Resampling

The primary challenge in vapor intrusion monitoring is distinguishing vapor intrusion from

other sources of exposure. In order to establish that VOCs are from soil vapor, rather than

from the surrounding environment, sampling systems (ports) must be tested with tracer

compounds, such as helium, and shown to be properly sealed. Sample collection system

integrity can be demonstrated by including the tracer gas in the list of target analytes report-

ed by the laboratory; however, if high levels are found the sample is rejected and costly

resampling may result.

Using a Leak Detector in the Field Saves Time and Money

Detection of tracer gas in the field is a cost-effective alternative to lab analysis that assures the

integrity of the sampling system before sampling occurs. The Restek Leak Detector provides

good screening of helium tracer gas at concentrations of 10%, the level at which sample port

resealing is required. In addition, this unit is just a fraction of the cost of other field portable

devices, such as photionization detectors, which may be too sensitive for screening purposes.

Real-time detection of helium tracer gas in the field using a Restek Leak Detector as shown in

Figure 1 is a simple, inexpensive way to minimize resampling by establishing system integrity

prior to sample collection. Centek Laboratories pioneered this technique and contributed to its

inclusion in the New York State Department of Health method[1].

Website :

www.chromtech.net.auE-mail :

info@chromtech.net.auTelNo : 03 9762 2034 . . . in AUSTRALIA