Innovators of High Resolution

Chromatography Products

the

in this issue

MTBE & Oxygenate Analysis Using an

Rtx

®

-VGC Capillary GC Column

…pg. 6–7

New Analytical Reference Materials

…pg. 8–9

Tips for Maximizing

HPLC Column Lifetime

…pg. 10

Fast GC Analysis with the

GC Racer System

…pg. 11

Inert Inlet System Improves Responses

for Chlorinated Pesticides

…pg. 12–13

Analyzing Organophosphorus

Pesticides

…pg. 14–15

Merlin Microseal

®

Septa

…pg. 15

Behind the Scenes

…pg. 16

www.restekcorp.com2002

vol. 2

by Donna Lidgett, GC Accessories Product Marketing Manager

Leak-Tight Seal for Agilent GCs

Vespel

®

Ring Inlet Seals

Advantage

Vespel

®

Ring

Inlet Seals

…pg. 1–2

Cool Tools

…pg. 2

High-Speed Analysis of

Petrochemicals

…pg. 3

HPLC Analysis of

Preservatives

…pg. 4–5

In Agilent split/splitless injection ports, the inlet

seal sits at the base of the injector. Dirt, non-volatile

residue, septum fragments, and other undesirable

particles contaminate the inlet seal and decrease

analytical linearity. The only way to maintain opti-

mum performance is by frequently changing the

inlet seal and ensuring the seal is leak-tight.

✔

Easy to use—Vespel

®

material seals the first time, every time, reducing variability

among operators.

✔

Better sensitivity—lower leak rate reduces detector noise.

✔

Saves money—prevents oxygen from permeating the carrier gas, increasing

column lifetime.

✔

Less maintenance—soft sealing area reduces wear on the injection port body.

Restek designed the Vespel

®

Ring Inlet Seal to

improve injection port performance on two levels.

First, the Vespel

®

Ring Inlet Seal is made from

high-quality stainless steel and features a Vespel

®

ring embedded into its face. This soft Vespel

®

ring

will not harm the critical seal on the bottom of the

injector body, and is outside the sample flow path,

for worry-free chromatography.

Second, the Vespel

®

Ring Inlet Seal is designed to

seal even after repeated temperature cycles and

without retightening the reducing nut! With tradi-

tional stainless steel inlet seals, it is difficult to

tighten to achieve a leak-tight seal. To determine

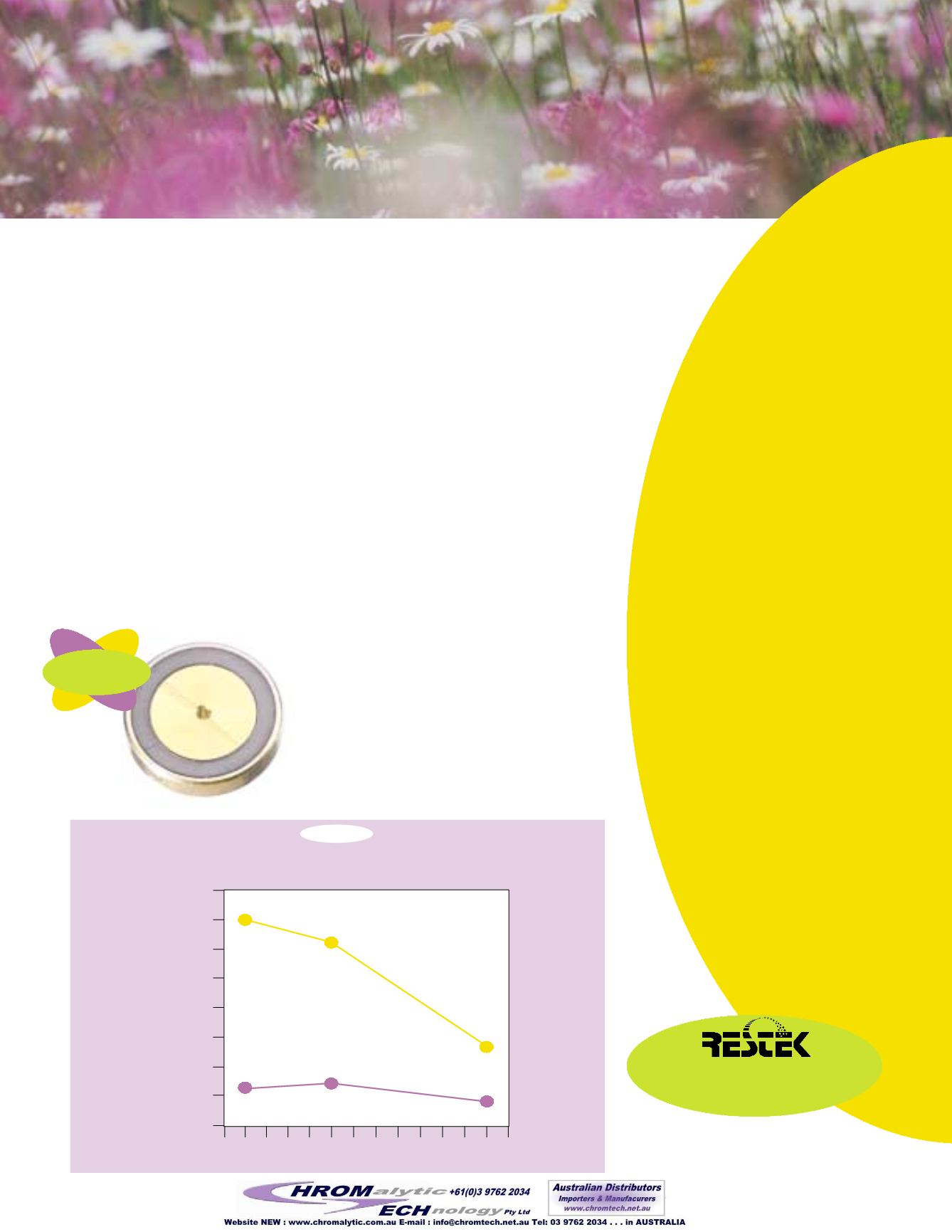

the variances between a traditional seal and the

new Vespel

®

Ring Inlet Seal, we compared the leak

rate for each type of seal at increasing torque

(Figure 1). Several inlet seals of each type were

Figure 1

The Vespel

®

Ring Inlet Seal achieves leak-tight seals even at low torque, reducing injection port

wear and the chances of damaging the injection port.

Torque (in lbs)

Leak Rate (Log

10

atm cc/sec.)

0 10 20

30

40

0.01

1E-3

1E-4

1E-5

1E-6

1E-7

1E-8

1E-9

1E-10

50

60

Vespel

®

Ring Inlet Seal

stainless steel

original equipment

inlet seal

new

patent

pending