pharmaceutical

Applications

note

RestekCorporation • (800)356-1688 • (814)353-1300 •

#59133

pharmaceutical

1

0 1 2 3 4 5 6 7 8min.

2 3

4

Excellent LC/MS Separation of Penicillins and Cephalosporins Using

Ultra IBD Columns

Antibiotics are the most widely used medications in the

world. Whether by prescription, addition to animal feed

stocks, or use of cleaning agents, everyone in the civilized

world is either directly or indirectly exposed to antibiotics

in daily life. The overuse of antibiotics, however, has

allowed resistant bacteria to thrive. The death of 12,500

people in Guatemala from an episode of Shingella fever can

be traced to a simple mutation of the bacterial strain.

Research indicated that the bacterium incorporated a single

plasmid into its RNA sequence and resultantly became

resistant to four different antibiotics. This illustrates the

danger of resistance caused by adaptation. To combat

resistant bacteria, new antibiotic derivatives must be created

to overcome the bacteria’s new defense mechanisms.

Typically, HPLC columns can be used to analyze penicillins

and their structurally related cephalosporins. However, the

similarity of many derivatives may require additional

interactions to effectively separate related compounds.

Restek’s Ultra IBD column is better able to resolve these

compounds using polar and hydrophobic interactions.

Background

Penicillins and cephalosporins represent nearly sixty percent

of antibiotics worldwide. These antibiotics possess a sulfur

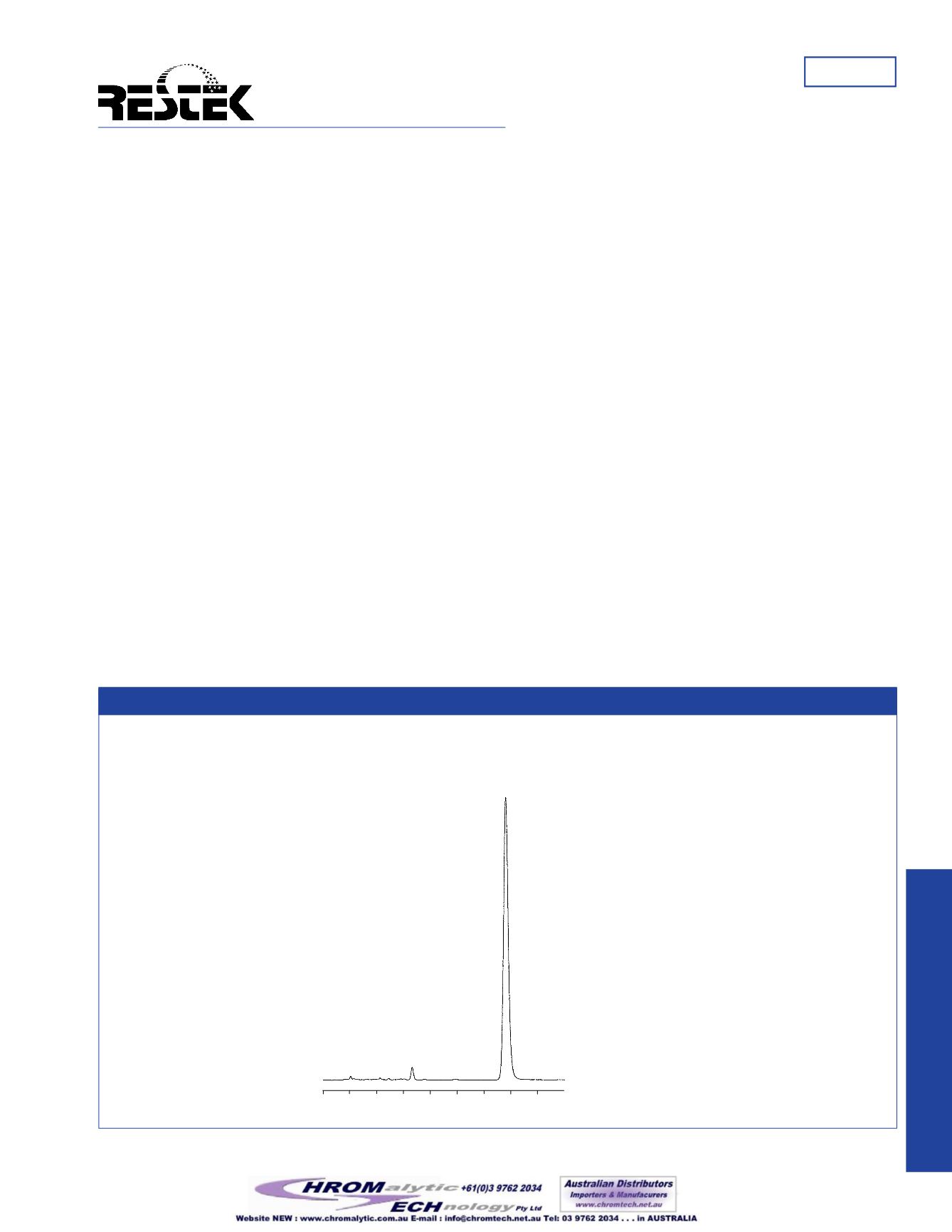

Figure1

Ultra IBD separates penicillinV from other fermentation impurities.

LC_0096

atom within a five- or six-membered ring, attached to a four-

member ß-lactam ring. They are produced by fermentation

processes using either selected fungi or species of

Strepto-

myces

bacteria. Derivatives are produced in two fashions:

1.

Biosynthetic process—The fungus or bacteria are

genetically engineered to produce a new derivative, or the

starting materials are altered to produce biosynthetic

variants during fermentation.

2.

Semi-synthetic processes—The materials from a biosyn-

thetic process are converted to chemical derivatives.

Penicillin derivatives are created from penicillin G or V,

while cephalosporin derivatives are created from cepha-

losporin C or cephamycin C.

Unfortunately, biosynthetic fermentation does not produce

a “pure” antibiotic. Even after cleanup of the fermentation

mash, some side reaction products will remain. Many of

these side products are closely related to the primary analyte

(Figure 1). Desired products, however, are created in the

semi-synthetic process. Penicillin V is converted to

amoxicillin through chemical intermediates and varies only

slightly in structure (Figure 2). Similar reactions also occur

during production of cephalosporin derivatives. The loss of

Peak List:

1. unknown

2. unknown

3. unknown

4. penicillin V

Sample:

Inj.:

2.5µL

Conc.:

1.2mg/mL

Solvent: acetonitrile:water (10:90, v/v)

Column:

Ultra IBD

Catalog #:

9175565

Dimensions:

150 x 4.6mm

Particle Size:

5µm

Pore Size:

100Å

Conditions:

Mobile Phase:

10mM ammonium

formate, pH 2.5:

acetonitrile (60:40, v/v)

Flow:

1.2mL/min.

Temp.:

30°C

Det.:

UV @ 270nm