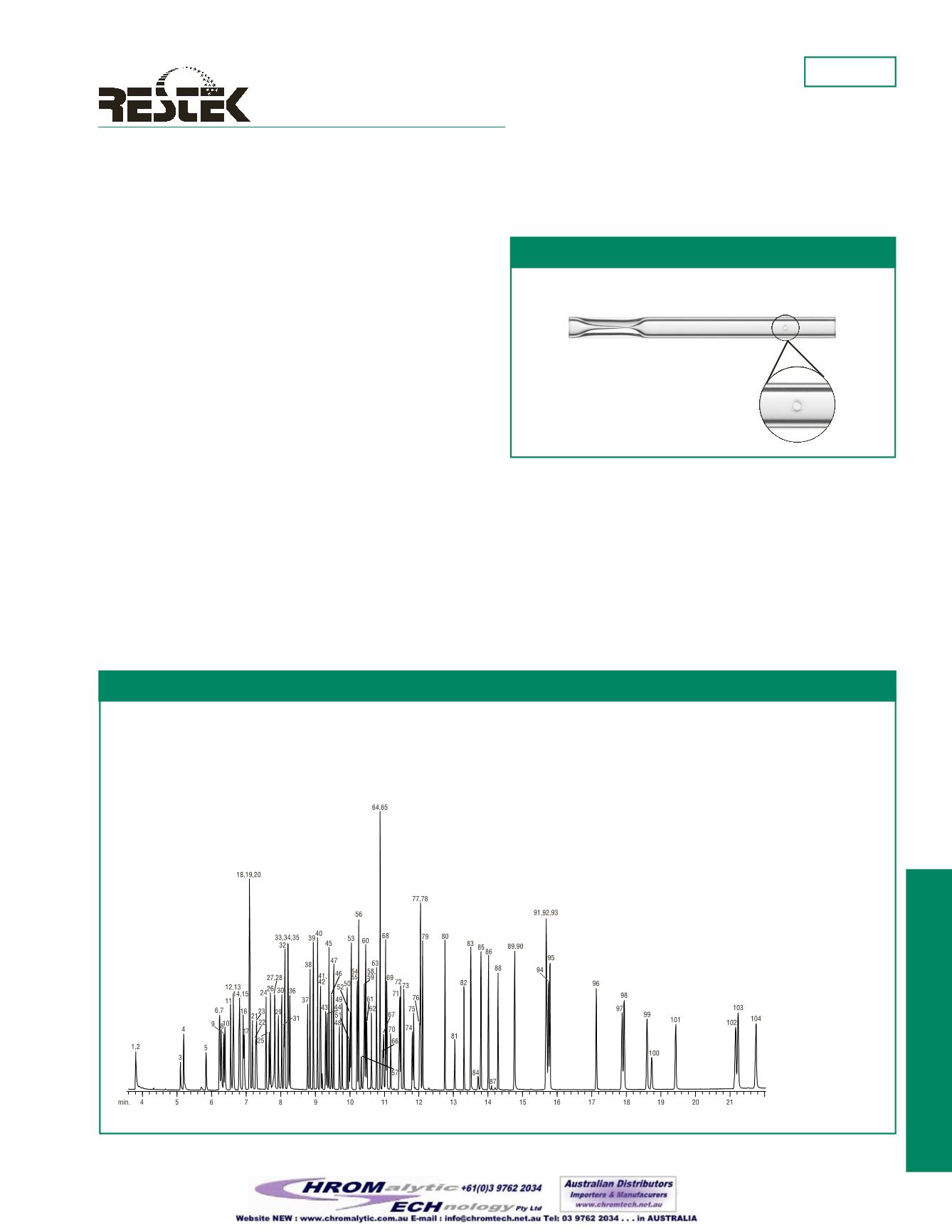

Figure 1

• Allows DI and splitless injections.

• Minimizes injection port

discrimination.

• Reduces loss of active compounds

formore accurate results.

The drilledUniliner

fi

liner providesmore accurate results.

environmental

Applications

note

Restek Corporation • (800) 356-1688 • (814) 353-1300 •

#59125

environmental

Improving throughput of semivolatileGC/MS analysis using a performance-

basedmeasurement system, Rtx

fi

-5Sil MS column, andUniliner

fi

inlet liner.

exposure to the injection port. This unique inlet liner can be used

for both direct and splitless injections. Because the column is

sealed to the liner with a press-tight connection, there is no chance

for any sample contact withmetal surfaces below the liner. The

small hole located on the side of theUnliner

fi

liner allows carrier

gas to be routed through the split vent line during the splitless

purge operation of the injection system. Because the drilled

Uniliner

fi

liner directsmore of the sample onto the column, less

discrimination of highmolecular weight compounds occurs.

Restek has developed aGC/MSmethod for analyzing semi-

volatile compounds (e.g., USEnvironmental ProtectionAgency

[EPA]Method 8270) that will help increase productivity in the

lab. The changes includemodifying the final extract volume,

using a drilledUniliner

fi

liner, optimizingGC analysis conditions,

andmodifying the calibration curve to offset the increased extract

volume. Following is an explanation of eachmodification.

1) Increase the final extract volume from 1mLto 5mL.

Increasing the final extract volumewill dilute the nonvolatile

material extracted from the sample, resulting in less contamina-

tion to the injection system and analytical column. This has the

potential to allow theGC/MS to stay in calibration longer, and to

reducemaintenance time and expense.Also, the increased extract

volumewill result in better recoveries of low-boiling compounds

that may be lost when the extract is concentrated to 1mL.

2) Replace the splitless inlet linerwith adrilledUniliner

fi

liner.

When the sample is injected into the injection port, it expands

and comes into contact with the bottom of the injection port. This

may cause adsorption or breakdown of the active compounds in

the sample.AdrilledUniliner

fi

liner (Figure 1) can be used in

place of a standard splitless liner to significantly reduce sample

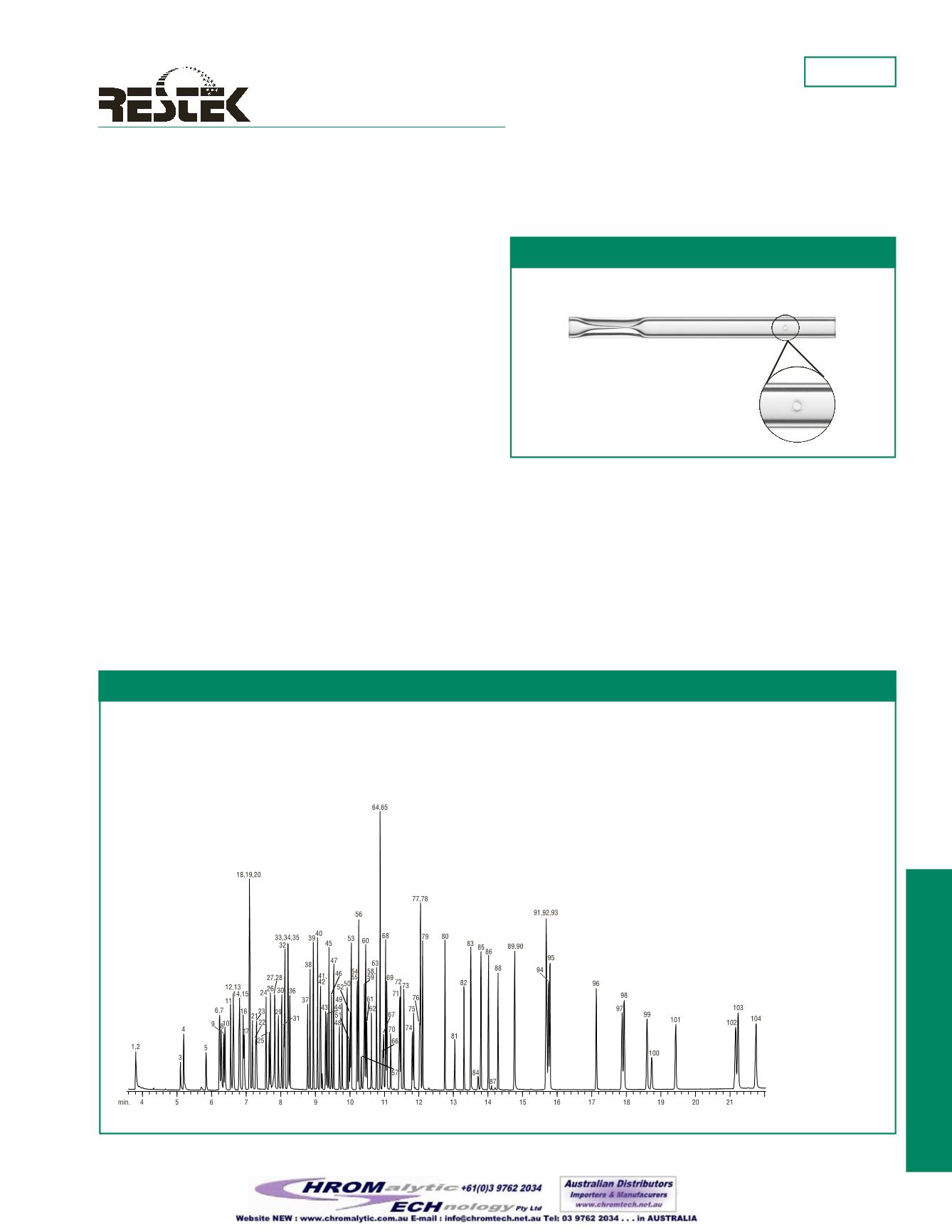

Figure 2

The Rtx

fi

-5SilMS column, combinedwith a Siltek -treated drilledUniliner

fi

liner, exhibits excellent peak

shape and response for semivolatile compounds.

Rtx

®

-5SilMS, 30m, 0.25mm ID, 0.25µm (cat.# 12723)

Sample:

16µg/mL inmethylene chloride, IS@

8µg/mL

Inj.:

1 µLsplitless (hold 0.4min.),

DrilledUniliner

®

liner (cat.# 21054)

Inj. temp.:

300°C

Carrier gas:

helium, constant flow

Flow rate:

1mL/min.

Oven temp.:

35°C (hold 2min.) to 260°C@

20°C/min.,

to 330°C@ 6°C/min. (hold 1min.)

Det.:

MS

Transfer line temp.: 280°C

Scan range:

35–550amu

Ionization:

EI

Mode:

full scan

Analytical ReferenceMaterials used:

cat.#’s 31618, 31619, 31620, 31621, 31622, 31206, 31062, 31063

GC_EV00561

See page 3 for peak list.

22