LD

P1000

Improve

you gas chromatograph measurement

The LDP1000 purifies noble gases, nitrogen or hydrogen

at level that give the best reference for any gas

chromatograph and GC/MS. Its non-evaporable zirconium-

based getter alloy is contained in a 316L Stainless Steel

bloc to ensure high purity and safe operating mode. It

removes impurities down to ppt level (total impurities).

N2

N2

N2

0

1

2

3

4

5

6

7

8

9

10

Time (min)

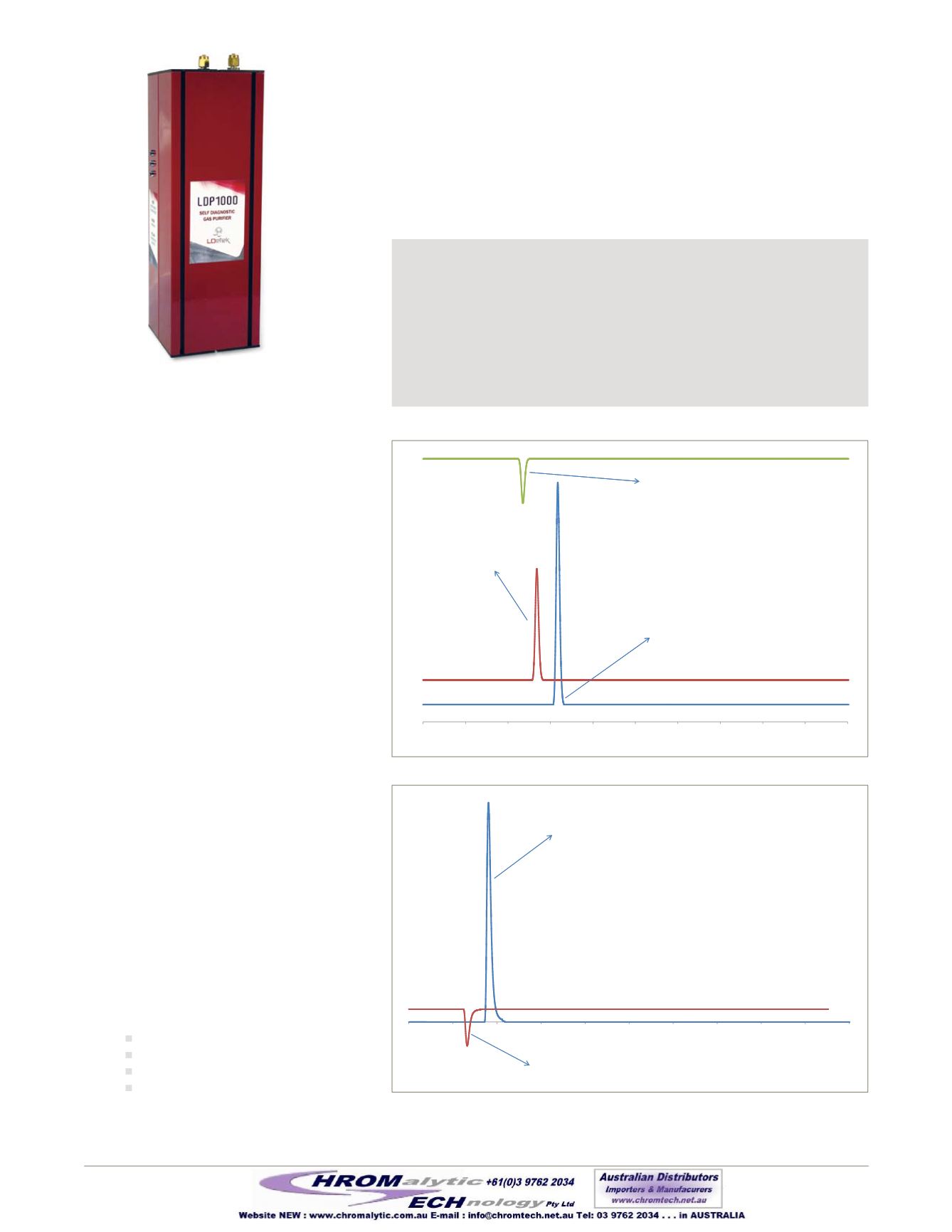

1ppm N2 sample gas

Chromatogram with LDP1000

Gas Purifier installed

1ppm N2 sample gas Chromatogram

with no LDP1000 Gas Purifier and 1.2ppm

Nitrogen contamination in carrier gas

1ppm N2 sample

gas Chromatogram

with no LDP1000

Gas Purifier and

0.5ppm Nitrogen

contamination

in carrier gas

Sensitivity improved

Having a contaminated carrier gas, sensitivity of the

impurities that need to be measured will be affected.

By using the LDP1000, you ensure that your GC

has the best reference gas to be able to get the

maximum performance of your detection system.

Contamination brings also an undesired level of

noise that affects as well the detection limit of

your system. The LDP1000 ensures to keep this

signal/noise ratio as high as possible.

It is even worse when the contamination is higher

than the sample to measure. Since the sample

is more pure than the carrier gas, you get a

negative peak for the impurity. The measurement

is completely erroneous and cannot be used.

Two beds of purification

To ensure high purity, the LDP1000 noble gas

version has two beds of purification. The first

stage has an elevated temperature grabbing all

components except some low level hydrogen. At

this temperature, some H

2

can be released from

this bed. The amount of H

2

can be as high as a

few hundred ppb with the use of one stage of

purification only.

By having a second bed of purification operating

at a different temperature, the hydrogen out of

the first stage can then be totally trapped.

Both bed temperatures are controlled by a

microprocessor ensuring stability and efficiency

of the purifier

0

1

2

3

4

5

6

7

8

9

10

400ppb H2 peak sample analysis

with LDP1000 Gas Purifier installed

on Carrier Gas.

400ppb H2 peak sample analysis with a

standard Heated Gas Purifier installed on Carrier Gas.

Features :

Interchangeable getter

Auto Diagnostic LEDs

Serial port

Extended lifetime

www.

ldetek

.com

Where

innovation

leads to

success

9