ANALYSIS OF IMPURITIES IN

ARGON USING COMPACTGC

WITH PLASMADETEK-2

Due to Helium shortage, gas suppliers see an increased request for alternative gases. Their clients demand high purity with exact

specification for various applications like instrumental use and industrial production. Often PDD (Pulsed Discharge Detector) is used

for measuring impurities in bulk gases. But in case of determining the purity of Argon, separation problems arise with this detector

because Helium is used as carrier gas and the bulk Argon elutes close to Oxygen. The Plasmadetek-2 from LDetek offers the perfect

solution here, since Argon is used as carrier gas, and therefore the bulk peak is not seen at all.

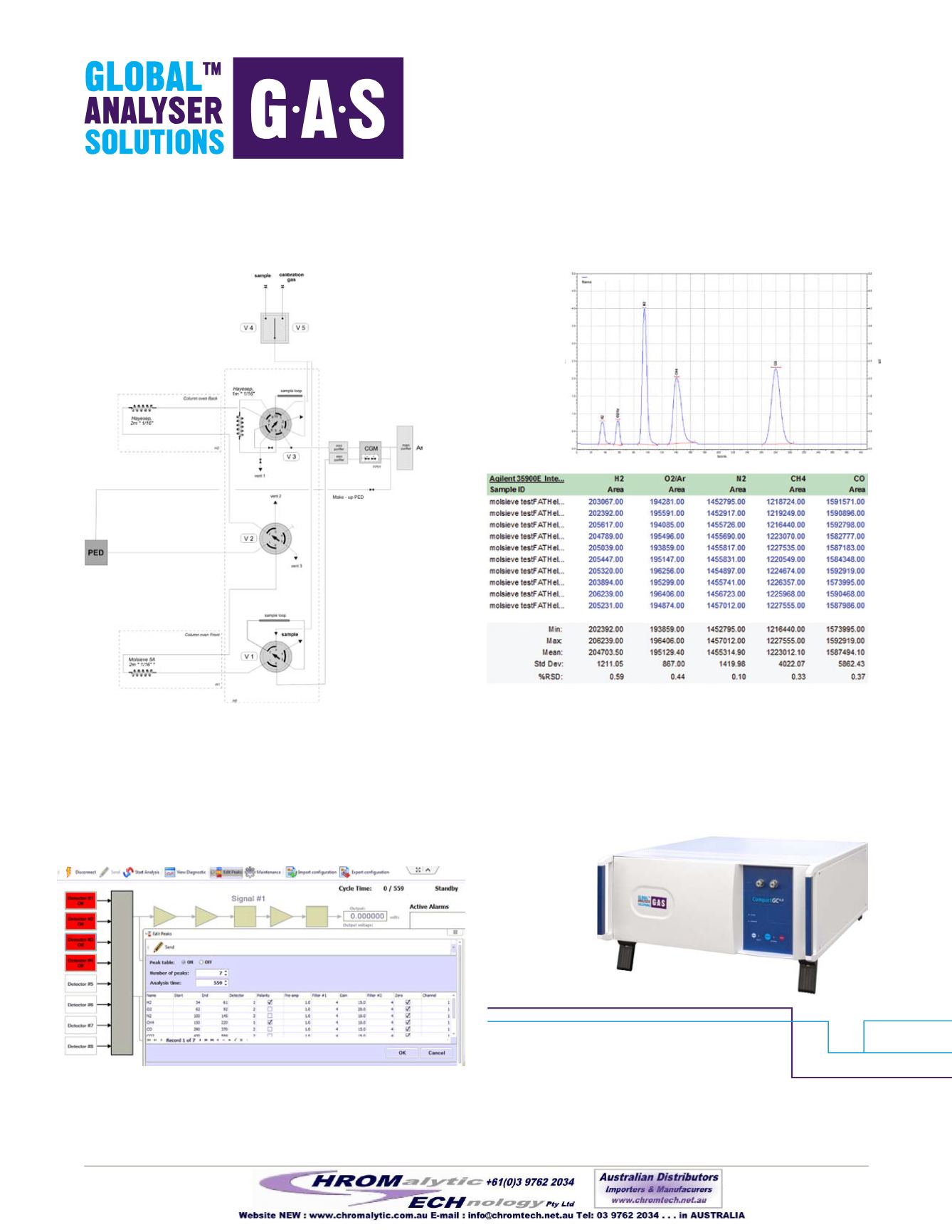

Figure 1 shows a two-channel analyser with single Plasma Emission Detector. Valve V1 and Molsieve column analyse H

2

, N

2

,

O

2

, CH

4

and CO in Ar. A second channel around valve V3 is present for analysing CH

4

, CO

2

, N

2

O and Ethane in Ar. For analysis of

impurities in N

2

, a fore-flush column switching option is added to this channel to vent the bulk N

2

. Figure 2 shows the Molsieve

chromagram of an 11 ppm calibration standard. Figure 3 demonstrates the obtained repeatability, which is excellent. Valve V2

combines both channels to a single PlasmaDetect-2 detector, which contains up to four optical sensors for optimal sensitivity for

each individual component, see figure 4. Figure 5 shows the integrated analyser using CompactGC

4.0

.

Figure 2

Chromatogram

Molsieve column

Figure 3 - Repeatability

Figure 4 - programming 4 optical sensors in one PlasmaDetect-2 detector

GLOBAL ANALYSER SOLUTIONS

P.O. Box 2148, 4800 CC Breda, The Netherlands

T: +31 (0)76 5411800 F: +31 (0)842 206757

info@gas-site.comwww.gas-site.com

Figure 1

Analyser diagram

Figure 5 - CompactGC

4.0

Where

innovation

leads to

success

www.

ldetek

.com

6