238

E

ENVIRONMENTAL CHAMBERS

Gas Cooled

GCC-Series, Gas Cooled Chambers

Direct injection liquefied gas cooling using liquid CO2

to achieve -60°C (or optionally using liquid nitrogen to

achieve -150°C) & rapid heating to 200°C as standard (or

optionally 300°C) all under the control of a sophisticated 8

segment pair controller. Enables the most rigorous temper-

ature test profiles to be used for accelerated age testing or

environmental simulation.

Thermal Range:

The working temperature range of the

chamber is -75°C to +400°C.

Thermal Performance:

The equipment has sufficient power

to enable a heating rate of up to 10°C/minute with a small

thermal load. Temperature stability under steady state

conditions is better than

±

0.5°C.

Temperature uniformity throughout the empty chamber

measured not less than 75mm from any surface is better

than

±

0.5°C.

Internal Chamber Construction:

The internal chamber is

fabricated from 304 grade polished stainless steel. All the

joints are externally sealed to prevent moisture entering

the insulation when the chamber is used at temperatures

below ambient.

External Construction:

The main case of the chamber is

fabricated from mild steel rectangular hollow section

panelled with zinc coated mild steel sheet. All external

surfaces are finished with grey powder paint.

Thermal Insulation:

The inner chamber is insulated with high

quality ceramic fibre and mineral wool blanket of

adequate thickness to ensure a safe outer case temp.

Chamber Door:

The chamber is fitted with a single door

that is hinged on the left hand side and opens to give full

access to the chamber. The door is fabricated from zinc

coated mild steel sheet for the exterior and 304 grade

stainless steel for the interior. The door is fitted with silicone

rubber door seals to reduce heat leakage through the

joints.

GCC30

Options:

●

Over-temperature protection to DIN 12-880 class 2

(recommended to protect valuable contents & for

unattended operation)

●

300°C optional maximum temperature

●

Optional liquid nitrogen injection system to reach

-150°C (including 2m insulated stainless steel pipe &

pressure relief valves)

●

Access ports for cables & pipes

●

Programmable controls with additional segments &

multi-program capability

●

Interior light (subject to temperature limitations) or

through window illumination kit

●

Additional shelves as required

●

A wide range of sample loading & handling

accessories can also be supplied

●

Paperless DAQ (Data Acquisition) graphical

recorders available.

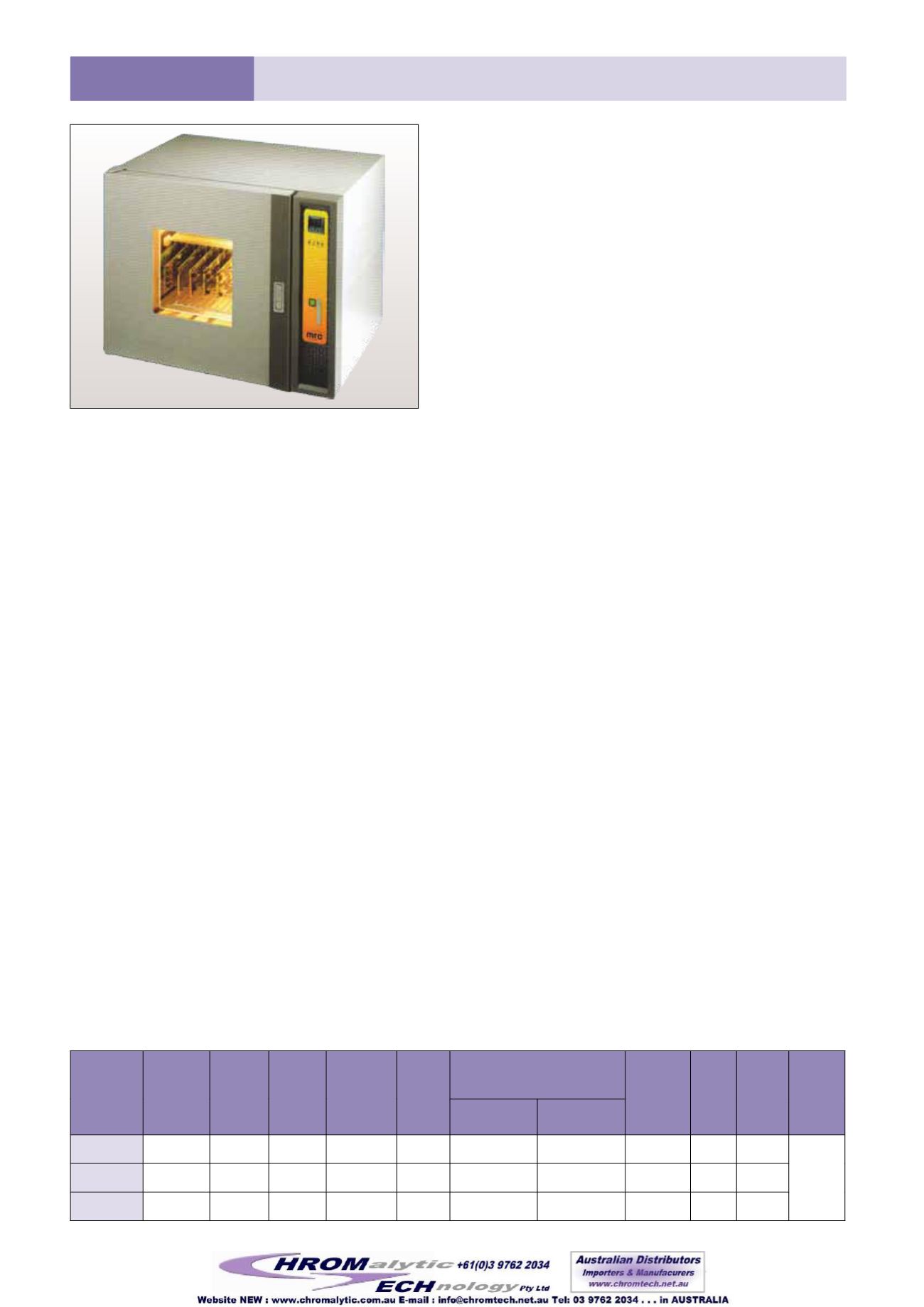

Model

Temp.

range

(

°

C)

Heat-up

time

to

Max.

(mins)

Temp.

stability

°

C

PID

Temp.

uniformity

300

°

C

(

±

°

C)

Cool-

down

time to

-60

°

C

(mins)

Dimensions

Shelves

Fitted/

accepted

Shelf

loading

Each/

total

(kg)

Max.

Power

200

°

C

Power

Supply

Internal

HxWxD(mm)

External

HxWxD(mm)

GCC30

-60 to 200 26

±

0.5

±

5.0

12 310x300x300 570x765x770 2/3

10

20 750

single

phase

GCC60

-60 to 200 26

±

0.5

±

5.0

12 410x400x380 670x865x870 2/5

10

30 1000

GCC120

-60 to 200 26

±

0.5

±

5.0

12 660x500x380 920x965x870 2/9

10

40 1500

Uniformity values are measured with vents closed in a steady state chamber after a stabilization period. Shelf loadings are based

on evenly distributed weight. Gas cylinders & Dewars are not included as part of the standard offer.

Access Ports:

A nominal 50mm diameter cable port is located centrally on the left hand side of the inner chamber

wall.

Air Circulation:

Forced air circulation is provided by a rear mounted fan. The fan is mounted behind an air guide to

prevent it being touched by the operator.

Shelves and Runners:

The chamber is supplied with three pairs of fixed shelf runners. Two perforated stainless steel

shelves are supplied.

Temperature Control:

The temperature of the chamber is controlled by a Eurotherm 3216 digital indicating

microprocessor based three term time/temperature program controller. The controller is fully adjustable and may be

"tuned" by the customer to suit the temperature and load in the chamber.

Under/Over Temperature Control:

A Eurotherm 2132 controller is fitted as a low and high temperature cut out. If a fault

causes the main set point temperature to be exceeded then a safety contactor will isolate the heating elements and

solenoid valves. The over temperature circuit must be manually reset when the chamber has warmed up or cooled

down and the fault has been cleared.

Heating System:

The chamber is heated by mineral insulated metal sheathed elements. The low surface watt loading

of the elements ensures a long and reliable service life.

Cooling System:

The chamber is cooled by liquid Nitrogen. A cool channel circuit in the controller switches a solenoid

valve to control the direct injection of liquid into the chamber. A second solenoid valve in the supply line is controlled

by the under temperature controller and will switch off the liquid Nitrogen if the direct injection valve fails in an open

condition. Appropriate pressure relief valves are included to ensure a safe working system. A two metre length of

insulated flexible stainless steel hose is supplied for connection of the equipment to the customers bulk supply.

Build Standards:

The oven is designed and built to good engineering practice in a facility having a certificated

quality assurance scheme to ISO 9001:2008. It complies fully with the relevant UK and European Union Health and

Safety at Work legislation. It is compliant with the EU Low Voltage and EMC directives and carries the CE mark.