treatment adds

value

to your process:

t *NQSPWFDPSSPTJPOQFSGPSNBODF

PG QSPEVDFEXBUFS FRVJQNFOU

CZ

10x.

t3FEVDFNBUFSJBM DPTU CZ

80%.

t *NQSPWFQFSGPSNBODFXJUIPVU

DPTUMZ DPNQPOFOU SFEFTJHO

®

1FOO5FDI%S

|

#FMMFGPOUF 1"

|

'BY

XXX4JMDP5FLDPN

Improve Corrosion Resistance of

Stainless Steel Tenfold or More in

ProducedWater Applications

Reduce downtime and extend system lifetime with

Silcolloy

®

1000 treatment.

Managingproducedwater has

become amajor challenge for the oil

andgas industry. Aswells age,

water production increases and is

expected to swell 50% inoffshore

applications alone over the next 10

years. Alongwith increased volume,

drillersmust contendwith a severely

corrosive environment of high salinity,

acids, and temperature.

*NQSPWFDPSSPTJPO SFTJTUBODF

XJUI4JMDPMMPZ

®

Silcolloy

®

1000 (acorrosion resistant,

highpurity silicon coating from

SilcoTek

®

) can improve the corrosion

performance of stainless steels used

inproducedwater environments by

anorder ofmagnitude ormore.

Silcolloy 1000 is aproprietary, patent-

edmulti-layer silicon coatingdesigned

to improve the corrosion resistance

of stainless steel andmany alloys in a

wide range of corrosive environments

(visit

for a com-

plete listingof compatibility).

*OEFQFOEFOU -BCPSBUPSZ5FTUJOH

Corrosion testingof Silcolloy 1000

treated 316L stainless steel and un-

treated 316L stainless steel according

toASTMG48,MethodB2 (72-hour

ferric chloridepitting and crevice cor-

rosion testing), shows corrosionof the

treated stainless steel is reducedby

anorder ofmagnitude, asmeasured

byweight loss (Figures 1 and 2).

Testingof Silcolloy 1000 treated

coupons in neutral and acidic chlo-

ride solutions, according toASTMG

61,

2

showsSilcolloy 1000 treatment

reduces corrosion rates by an impres-

sive 50x, compared tountreated 316L

stainless steel.

*NQSPWF4ZTUFN1FSGPSNBODF

Silcolloy 1000maintains

high systempurity,

demonstrates extreme

heat capability and

allows for leak-tight

systemperformance

when applied to steel,

stainless steel andalloy systems. Sil-

colloy 1000 is durable and #exible and

thin enough tomaintain tightmachine

tolerances. This allows the customer

to improve the corrosion resistance of

existing components or to add addi-

tional corrosion resistance to existing

designswithout having to allow for

tolerance changes duringmachining.

The unique non-line-of-sight chemi-

cal vapor deposition (CVD) process

produces a highpurity, #exible amor-

phous silicon layer that is diffused

into themetal lattice. The layer will

conform to themost intricate surface

whilemaintaininghighdimensional

tolerances. TheSilcolloy 1000 layer

will deformwith tubing surfaces,

allowing leak-free seals and radius

bends in tubing.

Applications Note

®

Lit Cat #ST009

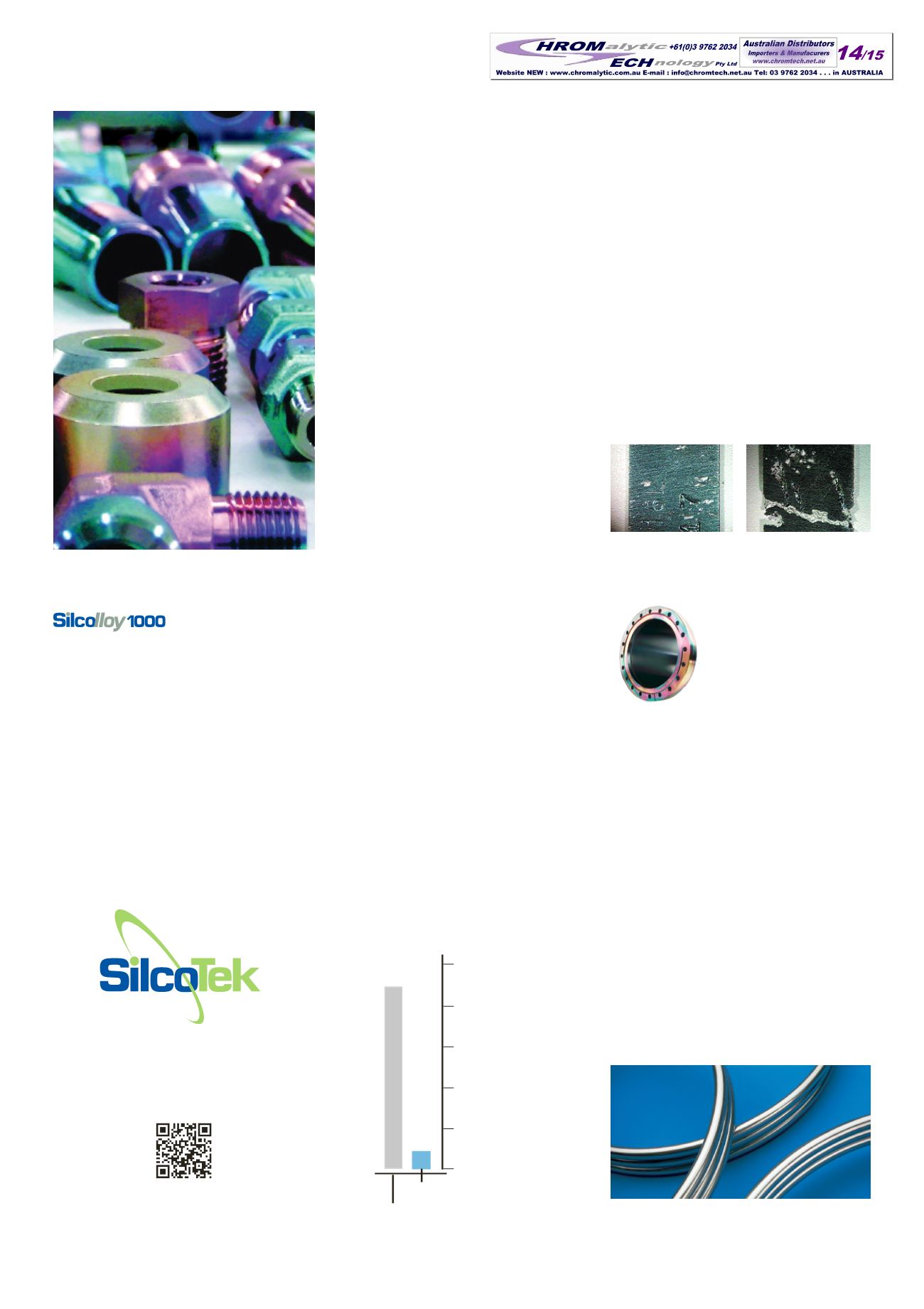

'JHVSF

Silcolloy 1000 treated stainless steel

outperforms uncoatedmetal by anorder of

magnitude (ASTMG 48,MethodB).

'JHVSF

Silcolloy 1000 treated coupon show

signi$cantly less corrosion attack compared to

anuntreated stainless steel coupon.

4JMDPMMPZ

®

USFBUFE

VOUSFBUFE

00

15

00

250

Untreated 316SS

Silcolloy

®

1000

weight loss in

grams per square

meter

2

0

0

1

0

5

2/28

35