®

Non-stick, Anti-coking,

Anti-fouling, Anti-sludge

SilcoKlean

®

1000 formerly Silcosteel

®

-AC

US Patent 6,444,326

®

1FOO5FDI%S

|

#FMMFGPOUF 1"

|

'BY

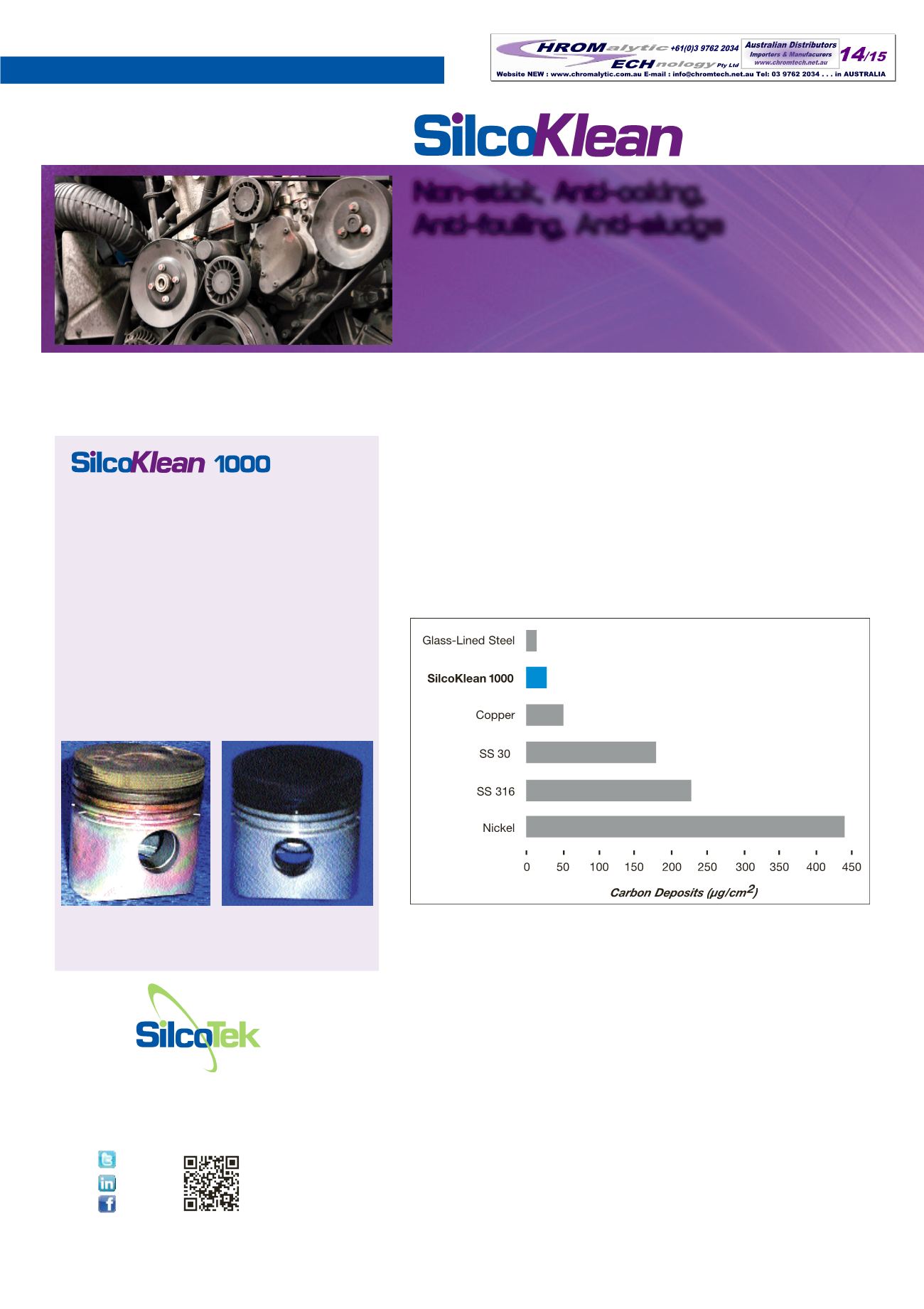

Reducecoke formation 8-foldwithSilcoKlean

®

1000

surface treatment

SilcoKlean

®

1000 reduces the formationof cokeby preventing exposed

metal surfaces from catalyzing fuel into carbon filaments. Figure 1

compares the carbon buildupon various surfaces. SilcoKlean 1000

reduces carbon foulingor cokingby 8-foldwhen compared to an

uncoated 316 stainless steel surface.

ASilcoKlean 1000 treated surface not only prevents the formation of

filamentous coke, it simplifies removal of other types of coke that typi-

cally bind to a heated surface.

Studies have shown that carbon deposits can be removed from a

SilcoKlean 1000 treated surface simply by sonicating the surface in

common solvents, thus dramatically simplifyingmaintenance proce-

dures and extendingmaintenance cycles.

3

(Figure 2)

SilcoKlean 1000 treatment extendsmaintenance cycles for engines

whilemaintaining high dimensional tolerances, high temperature capa-

bility, and leak-free conditions, making it an ideal treatment for:

t GVFM JOKFDUJPOOP[[MFT

t GVFM BOEPJM MJOFT

t KFU FOHJOFOP[[MFT

tQJTUPOT

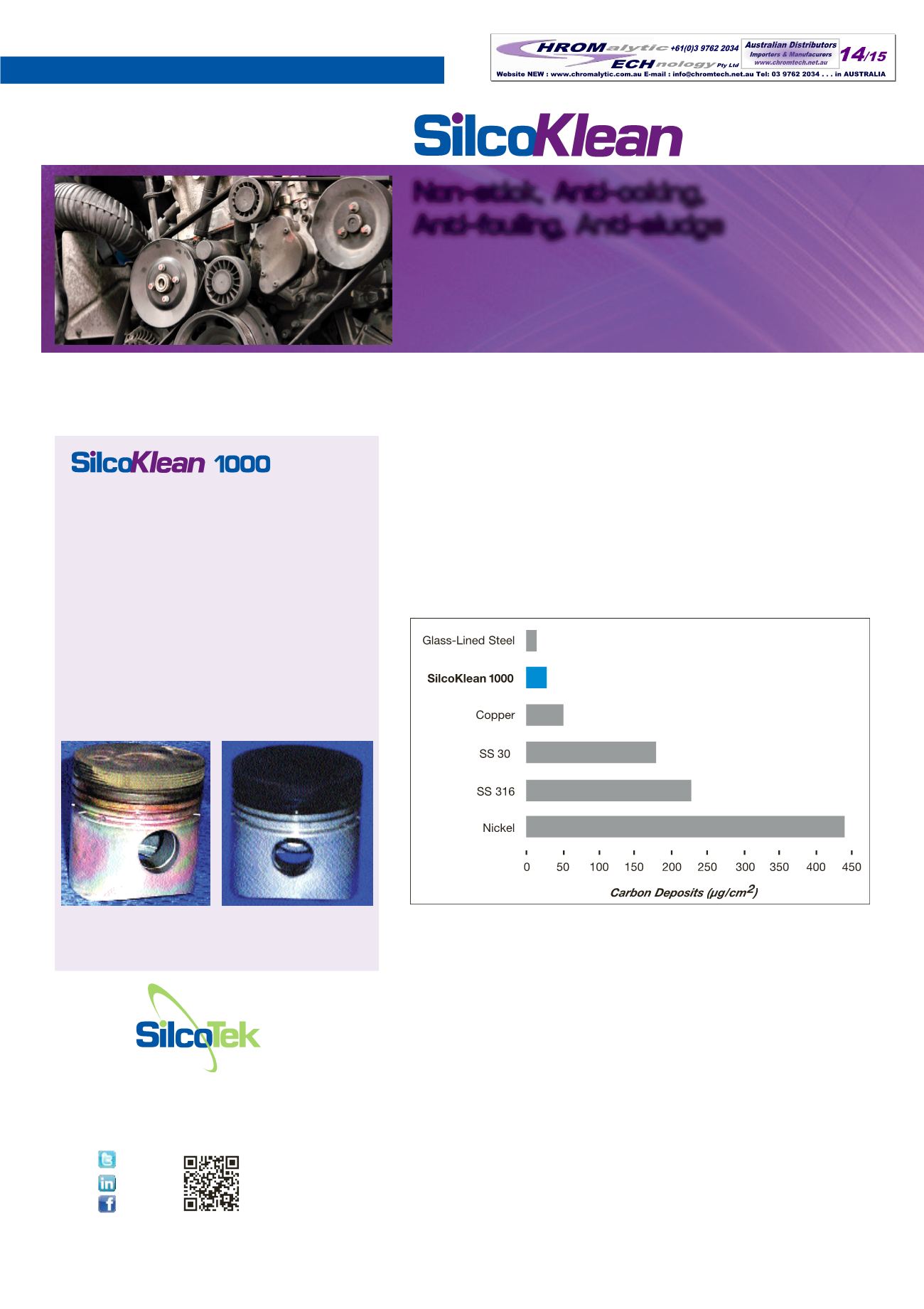

'JHVSF

ASilcoKlean1000-treatedpiston (left) shows dramati-

cally less cokebuildup than anuntreateddiesel piston (right).

Data courtesy of ThePennsylvaniaStateUniversity.

treatment adds value

to your process:

t *OIJCJUT DBUBMZUJDDPLJOH

t -POHFS DPNQPOFOU MJGFUJNFT

t %FDSFBTFENBJOUFOBODFDPTUT

t )JHIFS UIFSNBM FGmDJFODZ

t 8JMM XJUITUBOE UFNQFSBUVSFT

over 600ºC

t "QQMZ UPFYJTUJOHFRVJQNFOU

SilcoTek

®

surface treatments inhibit catalytic coking and carbon fouling.

®

4

®

'JHVSF

SilcoKlean1000 treatment reduces coking up to8-fold.

2

Data courtesy of ThePennsylvaniaStateUniversity.

t&(3TZTUFNT

t WBMWFT

t UVSCJOF TIBGUT

t IFBU FYDIBOHFST

2/28

29