Pressure-Programmed Carrier

Gas

Operation Using EPC System

INSTALLAnON

Chapter:

Topic:

(

i

i

1,

)

PRESSURE

PROGRAIII

FROIII

DATASYSTEIII

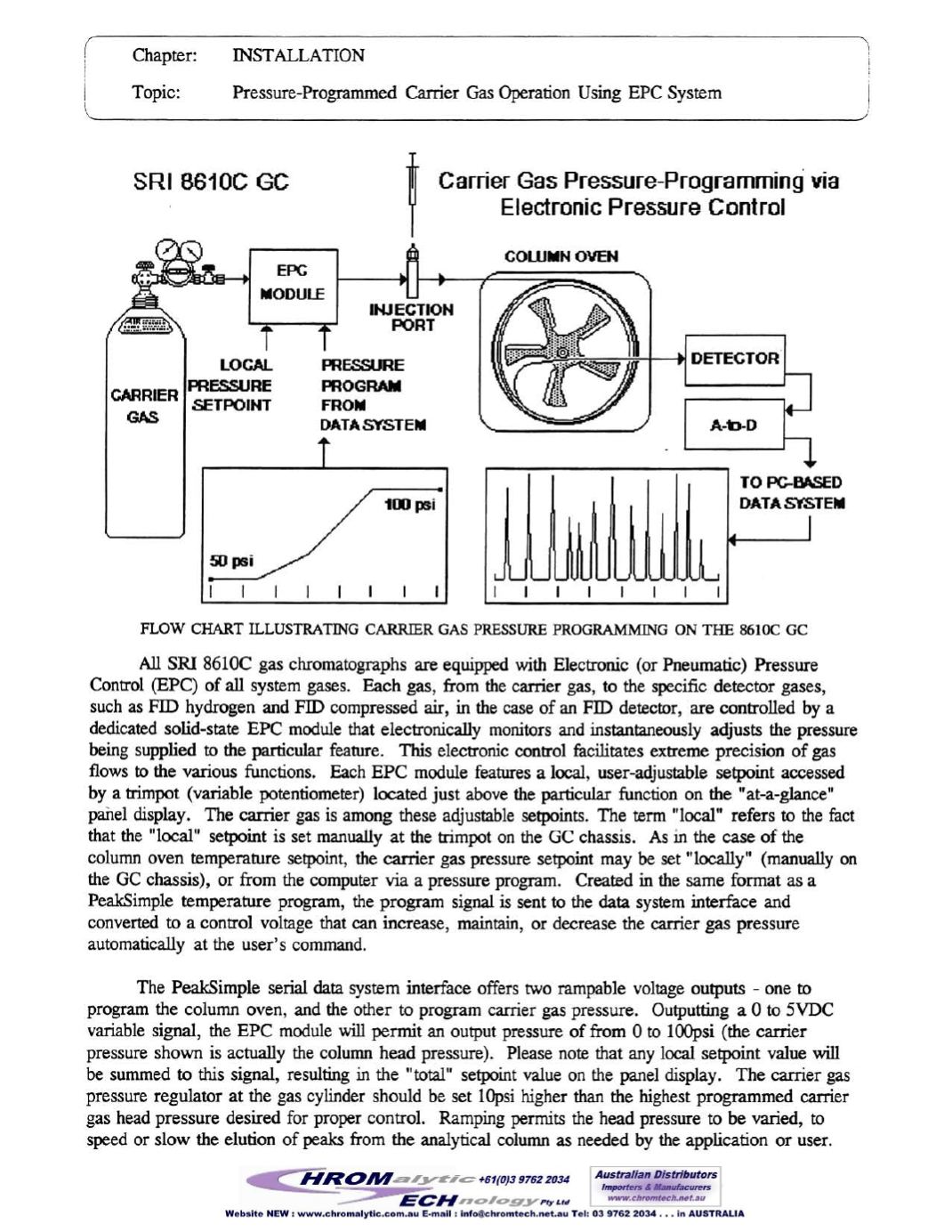

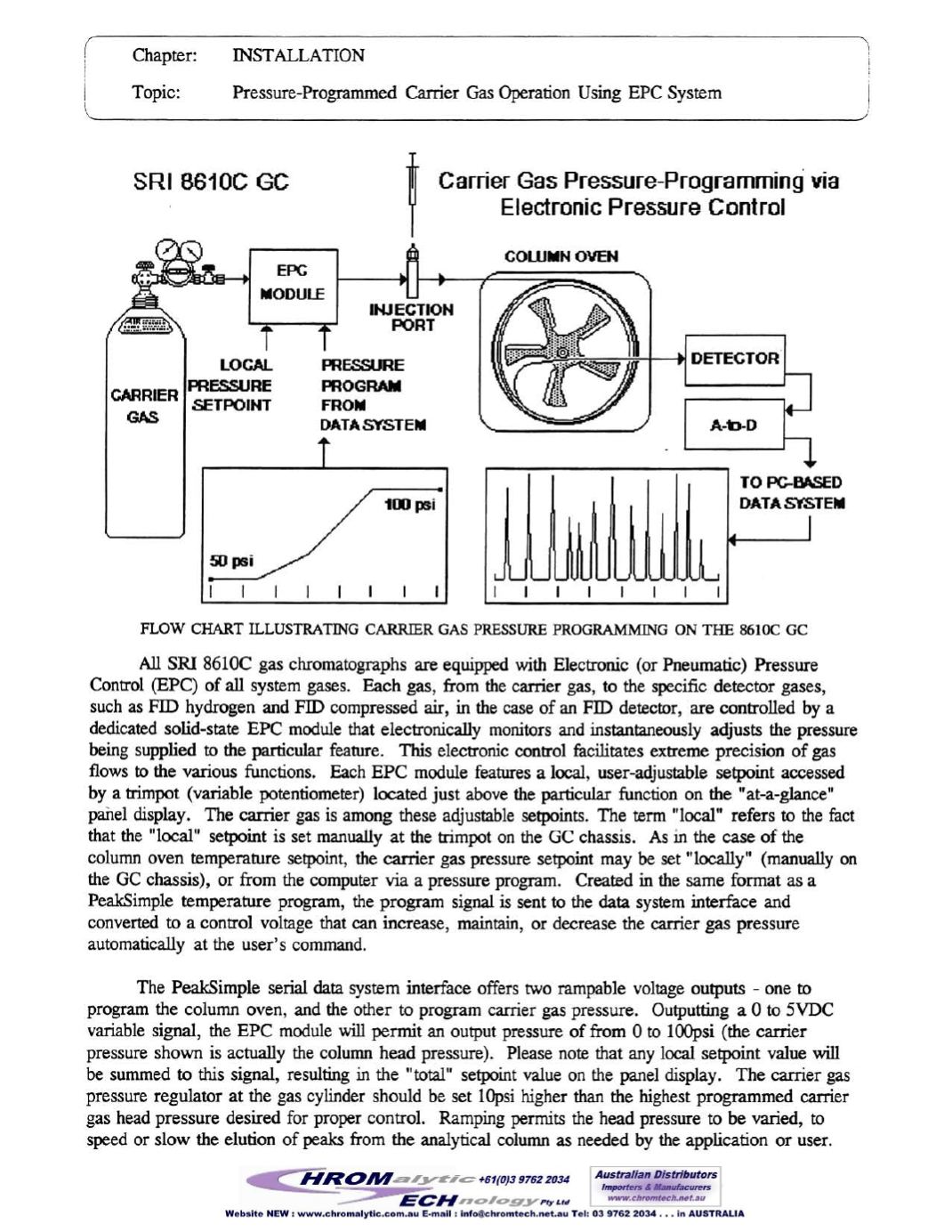

SRI 8610C GC

EPC

1II0DULE

LOCAL

PRI'SSlIRE

CARRIER SETPOINT

GAS

i

Carrier Gas Pressure-Programming via

r

Electronic Pressure Control

COWIIINOVEN

INJECTION

PORT

.-J}+--.I

DETECTOR

A·b·D

100

JBi

TOPC-8I\SED

DATASYSTEIII

5Dpsi

FLOW CHART ILLUSTRATING CARRIER GAS PRESSURE PROGRAMMrn"G ON THE 8610C GC

All SRI 8610C gas chromatographs are

equipped

with Electronic (or Pneumatic) Pressure

Control (EPC) of all system gases. Each gas, from the carrier gas,

to

the specific detector gases,

such as FID hydrogen and FID compressed air,

in

the case of an

Fill

detector, are controlled

by

a

dedicated solid-state EPC module

that

electronically monitors and instantaneously adjusts the pressure

being supplied

to

the particular feature. This electronic control facilitates extreme precision ofgas

flows

to

the various functions. Each EPC module features a local, user-adjustable setpoint accessed

by

a trimpot (variable potentiometer) located just above the particular function on the "at-a-glance"

panel display. The carrier gas is among these adjustable setpoints. The term "local" refers

to

the fact

that the "local" setpoint is set manually at the trimpot on the GC chassis. As in the case of the

column oven temperature setpoint, the carrier gas pressure setpoint may

be

set "locally" (manually on

the GC chassis), or from the computer

via

a pressure program. Created in the same format as a

PeakSimple temperature program, the program signal is sent to the data system interface and

convened

to

a control voltage that can increase, maintain, or decrease the carrier gas pressure

automatically at the user's command.

The PeakSimple serial data system interface offers two rampable voltage outputs - one to

program the column oven, and the other to program carrier gas pressure. Outputting a 0

to

5VDC

variable signal, the EPC module

will

permit an output pressure of from 0 to lOOpsi (the carrier

pressure shown is actually the column head pressure). Please note that any local setpoint value

will

be

summed

to

this signal, resulting

in

the "total" setpoint value on the panel display. The carrier gas

pressure regulator at the gas cylinder should

be

set IOpsi higher

than

the highest programmed carrier

gas head pressure desired for proper control. Ramping permits the head pressure

to

be

varied,

to

speed or slow the elution of peaks from the analytical column as needed by the application or user.