•

14

•

800-356-1688 •

www.restek.com2005 vol. 3

Introduction

Often, gas transfer systems require low moisture content, low moisture reten-

tion, and high resistance to corrosion. The current substrates of choice,

including electropolished VIM/VAR (vacuum induction melt/vacuum arc

melt) 316L stainless steel, typically are insufficient in these capacities, increas-

ing periodic maintenance, prolonging equilibration times, and allowing sys-

tem contamination and inaccurate analytical results. In contrast, surface treat-

ments available through the Restek Performance Coatings Group greatly

accelerate wet-up and dry-down times and dramatically improve corrosion

resistance.

Experiments measuring the response time for moisture content change in

Restek treated electropolished stainless steel tubing, untreated electropolished

stainless steel tubing, and standard 316L stainless steel tubing, demonstrate a

significant advantage in Restek treated substrates.¹ Wet-up curves for Siltek®

Superior Moisture Dry-Down and Corrosion Resistance

Restek treated tubing and system components improve

analytical reliability and prolong lifetimes.

By Gary Barone, Restek Performance Coatings Division Manager, David Smith, RPC Chief Scientist, and Martin Higgins, RPC Chief Engineer

• Up to three times faster response to moisture changes in process streams.

• Corrosion resistance improved tenfold, or more—prolongs component lifetime and maintains pure product stream.

• Custom services: can be applied to existing equipment.

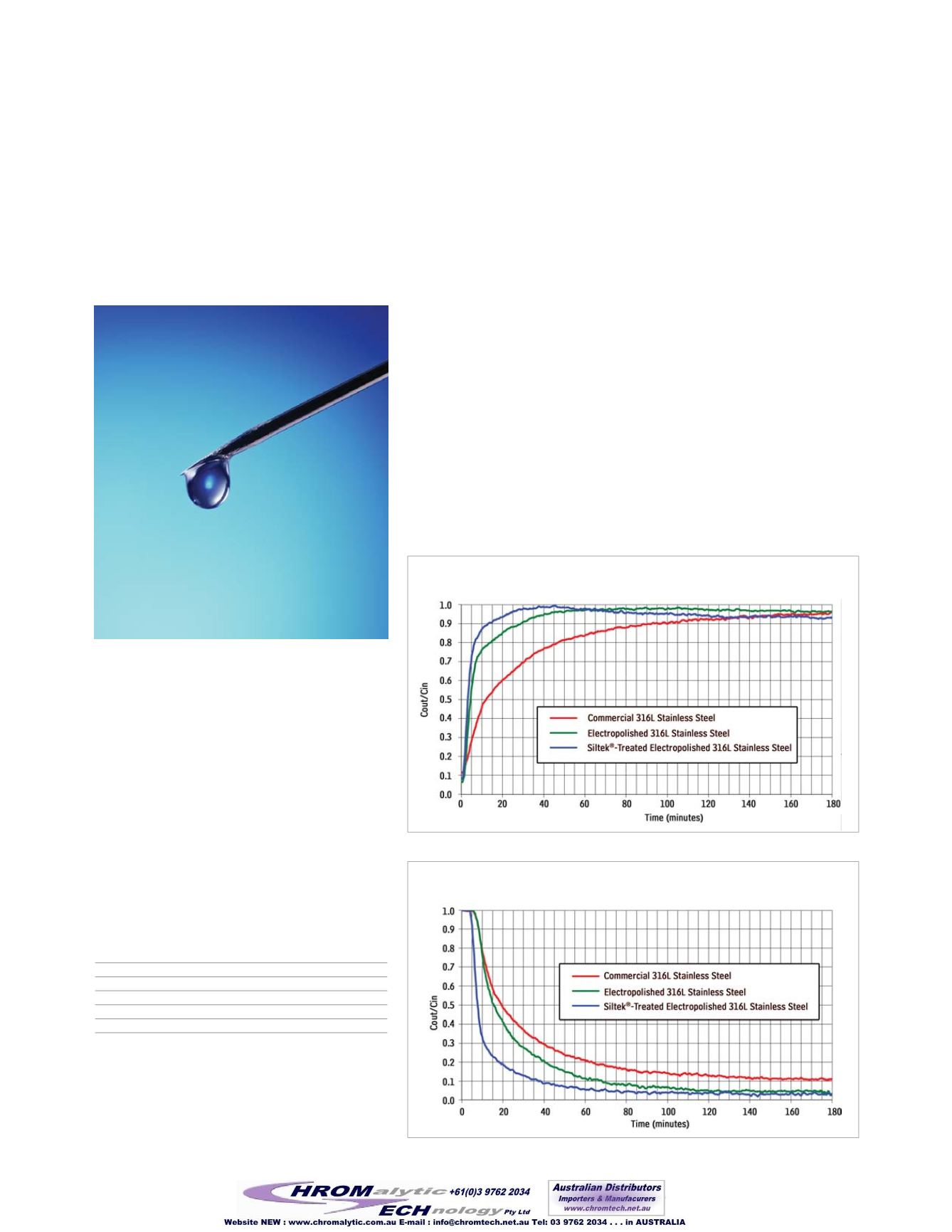

Figure 1

Restek treated electropolished tubing stabilizes at 1ppm

moisture much faster than conventional surfaces.

1

Figure 2

Restek treated electropolished tubing dries much faster

than conventional surfaces.

1

Table I

Restek treated electropolished

tubing provides the shortest drying times.

1

Time Require

d to

Detect Change (min.)

Moisture

Treated

Untreated

Concentration Electropolished Electropolished Standard

From

To

Tubing

Tubing

Tubing

10ppm* 5ppm 4

5

13

5ppm 1ppm 22

46

71

1ppm 500ppb

40

63

96

500ppb 100ppb

80

103

153

100ppb

50ppb

98

121

—

*Initial moisture concentration.

did

you

know?

Restek surface treatments deposit an amorphous silicon based

layer onto, and into, the steel surface through a chemical vapor

deposition (CVD) process. All exposed surfaces are coated. For

corrosion resistance, layer depth is optimized at 5 to 10 microns.

The amorphous silicon layer can be further functionalized using

the patented Siltek

®

process (US Patent #6,444,326), which

reduces moisture hold-up and improves surface inertness.