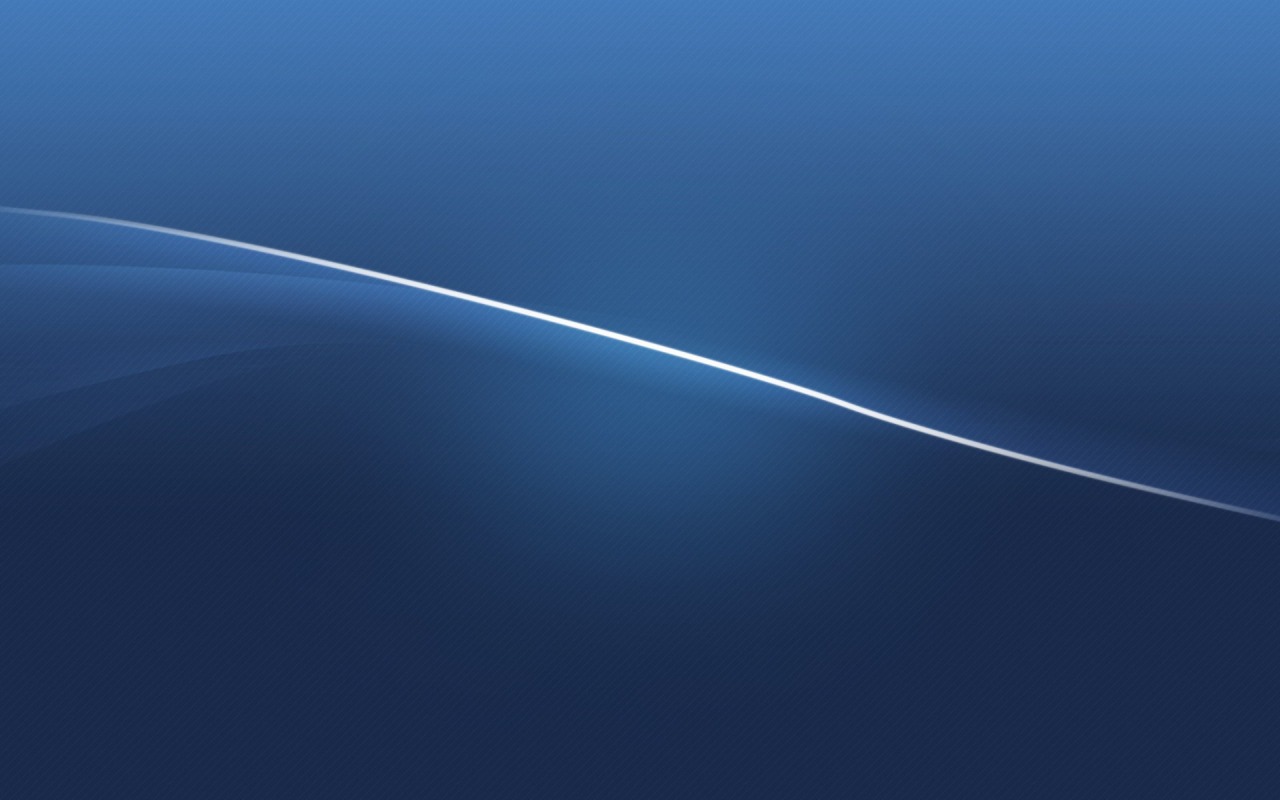

ASTM 6730 DHA Evaluation Mix

0

20

40

60

Time (min)

1

2

3

4

5

6

7

8

9

11

12

13

14

30 29

28

27

26

25

24

23

22

21

20 19

18

17

16

15

10

Peak #

1. ethanol

2. C5

3. t butanol

4. 2methylbutene2

5. 2,3 dimethylbutane

6. MTBE

7. C6

8. 1methylcyclopentene

9. Benzene

10. cyclohexane

11. 3 ethylpentane

12. 1 t 2 dimethylcyclopentane

13. C7

14. 2,2,3 trimethylpentane

15. 2,3,3 trimethylpentane

16.

Toluene

17.

C8

18.

Ethylbenzene

19.

P xylene

20.

2,3DMH

21.

C9

22.

5methylnonane

23.

1,2methylethylbenzene

24.

C10

25.

C11

26.

1,2,3,5,tetramethylbenzene

27.

Naphthalene

28.

C12

29.

1methylnaphthalene

30.

C13

Column :100m x 0.25mm Rtx-DHA-100,df =0.5um

Oven temp. : 5 ºC,( 6.5min.),18ºC/min→ 48ºC,( 30min.), 3.5ºC/min→ 200ºC

Carrier gas :H2,Flow5mL/min (ConstantFlow))

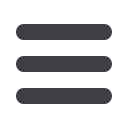

Focusing on Critical Areas of Resolution

3. t butanol

4. 2methylbutene 2

8. 1methylcyclopentene

9. Benzene

15. 2,3,3 trimethylpentane

16. 16.Toluene

3

4

9

8

16

15

Column :100m x 0.25mm Rtx-DHA-100,df =0.5um +2.6 m tuning column

Oven

:35C for 15minutes, than ramped to 250C at10/minuteand heldfor 20minutes.

Carrier

: H2,5mL/min, 64 cm/s

20 min

3.25>R <5.25

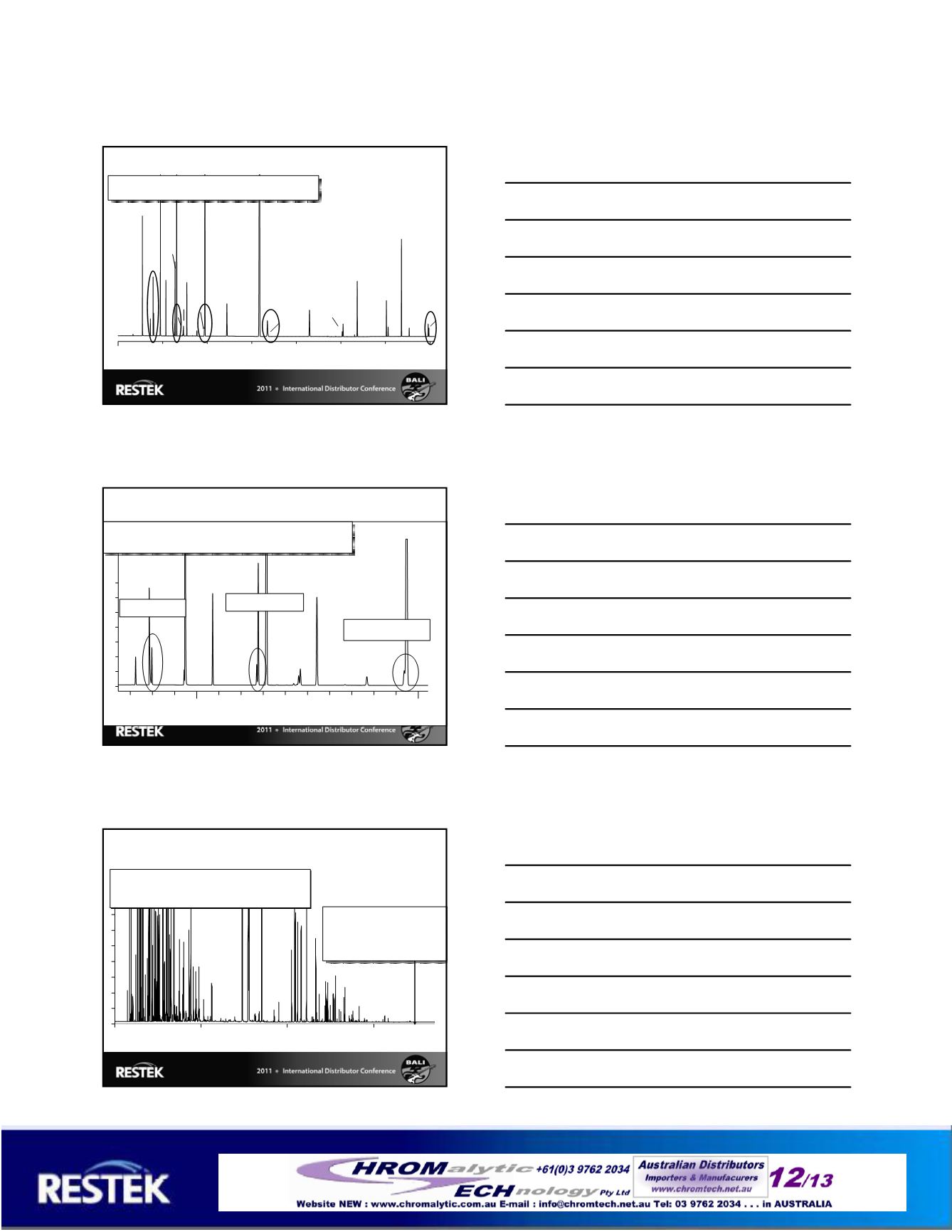

Gasoline Analysis Following ASTM D6730,

Helium as carrier gas

C3

n-C

n-C

n-C

n-C

n-C8

n-C9

n-C10

0

50

100

150

Column :100 x0.25mm Rtx-DHA-100 , tuned5%phenyl PDMS

Oven

:5°C, 10min -> 50°C, 5°C/min,54min, --> 200°C, 1.3 °C/min

Carrier gas : He, 24 cm/s, 39.3 Psi; Injection Split, 1 : 150; Detection :

FID;

Following the 6730 method:

Near

3

hours analysis time;

Using HELIUM