CV-3001

InlineCheckValveCartridge

CV-3000

InlineCheckValve

Includes (1)CV-3001

CartridgeandFlangeless

Fittings for 1/16”OD tubing

InlineCartridgeCheckValves

XX

Low crackingpressures

XX

Less than150µL internal volume

XX

Materials of construction: PEEK; perfluoroelastomer (CV-3001);

gold-plated stainless steel spring (CV-3001); ethylenepropylene

(CV-3011); and stainless steel spring (CV-3011)

UpchurchScientific

®

cartridge-style InlineCheckValvesaredesignedto

limitflowtoonedirection.Theseassemblieswithstandsystempressures

of 1,000psi (69bar).Thecrackingpressures for the InlineCheckValve

Cartridges are 1.5 psi (0.1 bar) for theCV-3001 and 3 psi (0.2 bar)

for theCV-3011. Toleranceon the crackingpressure for CV-3001 is

±0.5psi (0.03bar) and±1.5psi (0.1bar) onCV-3011.

Quick-StopLuer InlineCheckValve

XX

Check valveprotectionwith luer convenience

XX

Remains openwhenengaged

XX

Materials of construction: PEEK, perfluoroelastomer,

andgold-plated stainless steel spring

TheQuick-Stop Luer Check Valve is designed toprovide inline luer

connect/disconnect conveniencewithout themess and hazard of

spills. Just connect the valve assembly to your inline tubing using

standard 1/4-28 flat-bottom fittings (see pages 22–29). The check

valve is automaticallyopenedonce the luer connection is engaged,

allowingflow ineitherdirection.Disconnecting the luer unioncauses

the check valve to close. Please see the “ApplicationNote”on this

page for specific ideas regardinguseof this valve.

P-696Quick-StopLuerCheckValveAssembly.

Inlet Solvent Reservoir:

Quicklychange your solvent on the lowpressureendof anHPLC

system,whilepreventingpotentiallyhazardous spills! Just install a

Quick-StopLuerCheckValveAssemblybetween your solvent reservoir

and thepump,with the valve towards thebottle. The valvewill prevent

solvent leakage from the linecoming from the reservoir,while thecheck

valves in your pumpprevent spills from the line leading to thepump.

Withboth lines still full of solvent, this systemalsohelps reduce the

need to reprime yourpump.

FIASample Injection:

TheQuick-StopLuerCheckValveprovidesapracticalmeans to

introducea sample intoFIAandother lowpressure systems,whenused

inconjunctionwithaP-612PressureRelief ValveTee (page154). Simply

connect theTee into theappropriateflowpath linewith the included

fittingsand thread theP-697Quick-StopLuerValveonto the1/4-28male

endof theTee. Samplecan thenbe introducedconvenientlybyusinga

standard luer-tipped syringe. Thecheckvalve isautomaticallyopened

when the syringe isattachedandclosedwhen the syringe is removed.

PostColumnDerivitization:

For post-columnderivitization, placeaCV-3000 InlineCheckValveon

theeffluent sideof your column topreventderivatizingagents from

flowingbackwardsandpoisoning thecolumn. Placement on thepost-

column reagent linewill alsopreventmobilephase fromcontaminating

the reagent if theauxiliarypump fails.

HeliumSpargingTankProtection:

Try theCV-3010Assembly, designed specifically fordegassing

(sparging) lines toprevent solventbackup if the sparginggas runsout.

This check valvewill helppreventpotential solvent cross-contamination

anddamage to thegas regulating valve.

APPLICATIONNOTE

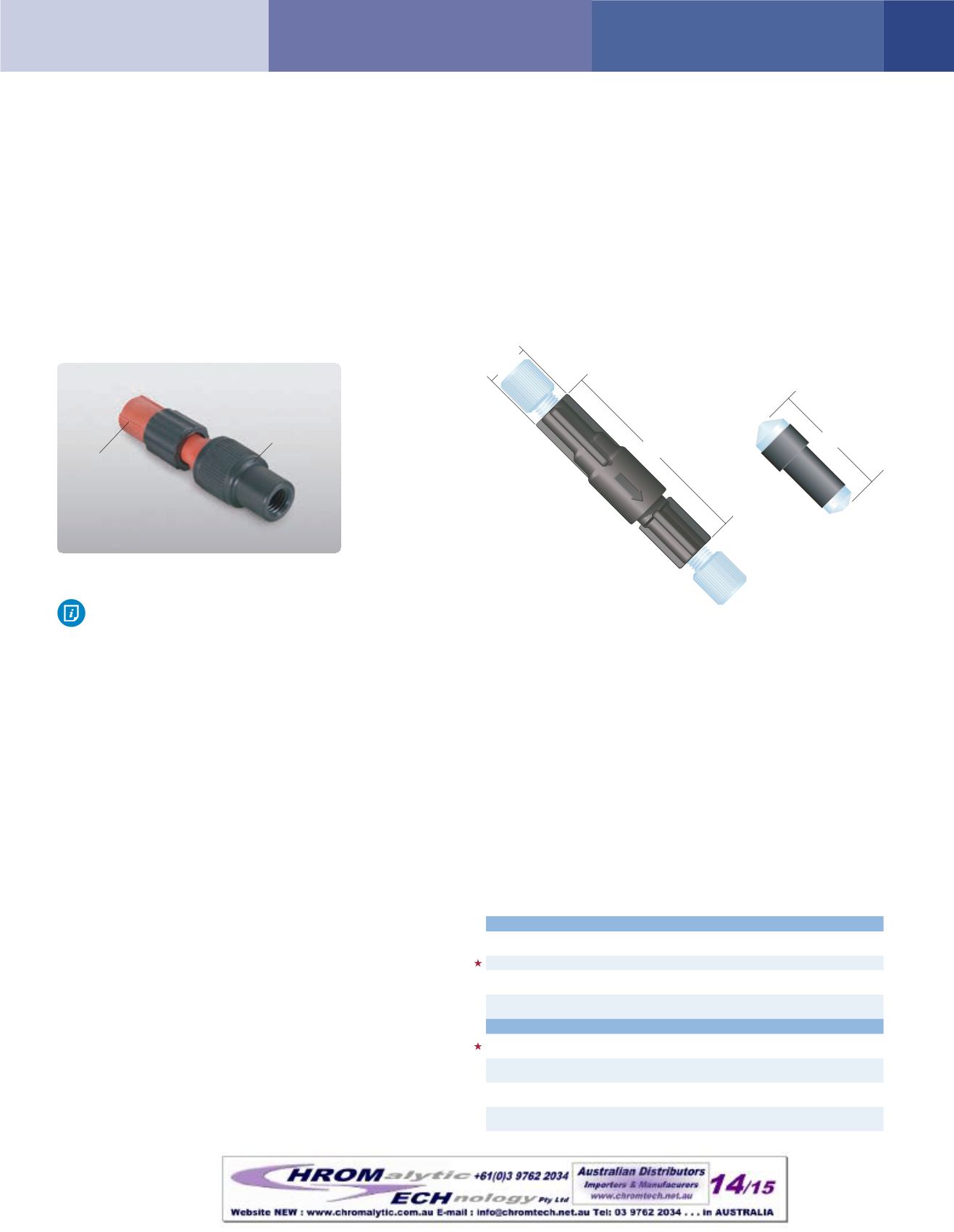

P-655

P-697

1.04”

(2.64cm)

0.42”

(1.07cm)

1.92”

(4.88cm)

PartNo.

Description

Includes

SweptVolume

QUICK-STOP LUERCHECKVALVE

P-696

Quick-Stop Luer

CheckValveAssembly

(1) P-697, (1) P-655

127µL

P-697

Quick-Stop Luer CheckValve

107µL

P-698

BulkheadQuick-Stop

Luer ValveAssembly

(1) P-699, (1) P-655,

(1) nut/lockwasher set

127µL

P-699

BulkheadQuick-Stop

Luer Valve

(1) nut/lockwasher set

107µL

INLINECARTRIDGECHECKVALVES

CV-3000

InlineCheckValveAssembly

for 1/16”OD tubing

(1) CV-3001, (2) XP-215

96µL

CV-3001

InlineCheckValveCartridge

for CV-3000

91µL

CV-3010

InlineCheckValveAssembly

for 1/8”OD tubing

(1) CV-3011, (2) XP-315

100µL

CV-3011

InlineCheckValveCartridge

for CV-3010

92µL

CHECKVALVES&

PRESSUREREGULATORS

151

InlineCheck Valves