13

Problems Associatedwith Split and Splitless Injections

When performed properly, split and splitless injections are easy to automate, produce nar-

row peaks, and yield consistent run-to-run peak areas. However, split and splitless injections

have inherent limitations associatedwith vaporizing the sample in a hot injection port.

Thermal Decomposition:

The injection port temperature is a critical factor in optimizing

hot vaporization injection techniques. If the injection port temperature is too low, high

molecular weight analyteswill not vaporize completely andwill not be transferred to the

head of the column efficiently (as shown by peaks 14, 15 and 16 in Figure 9). If the injec-

tion port temperature is too high, thermally labile compounds can break down inside the

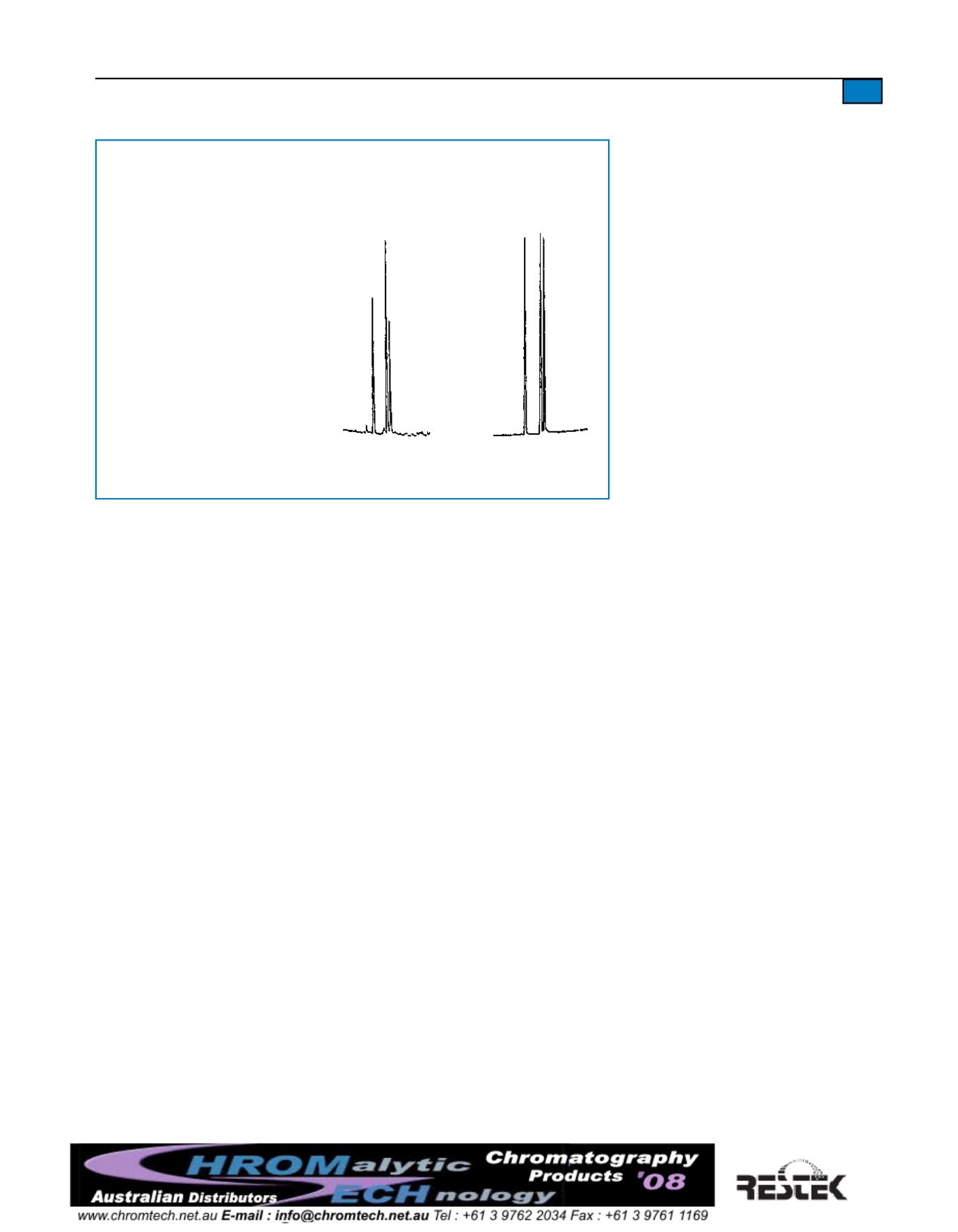

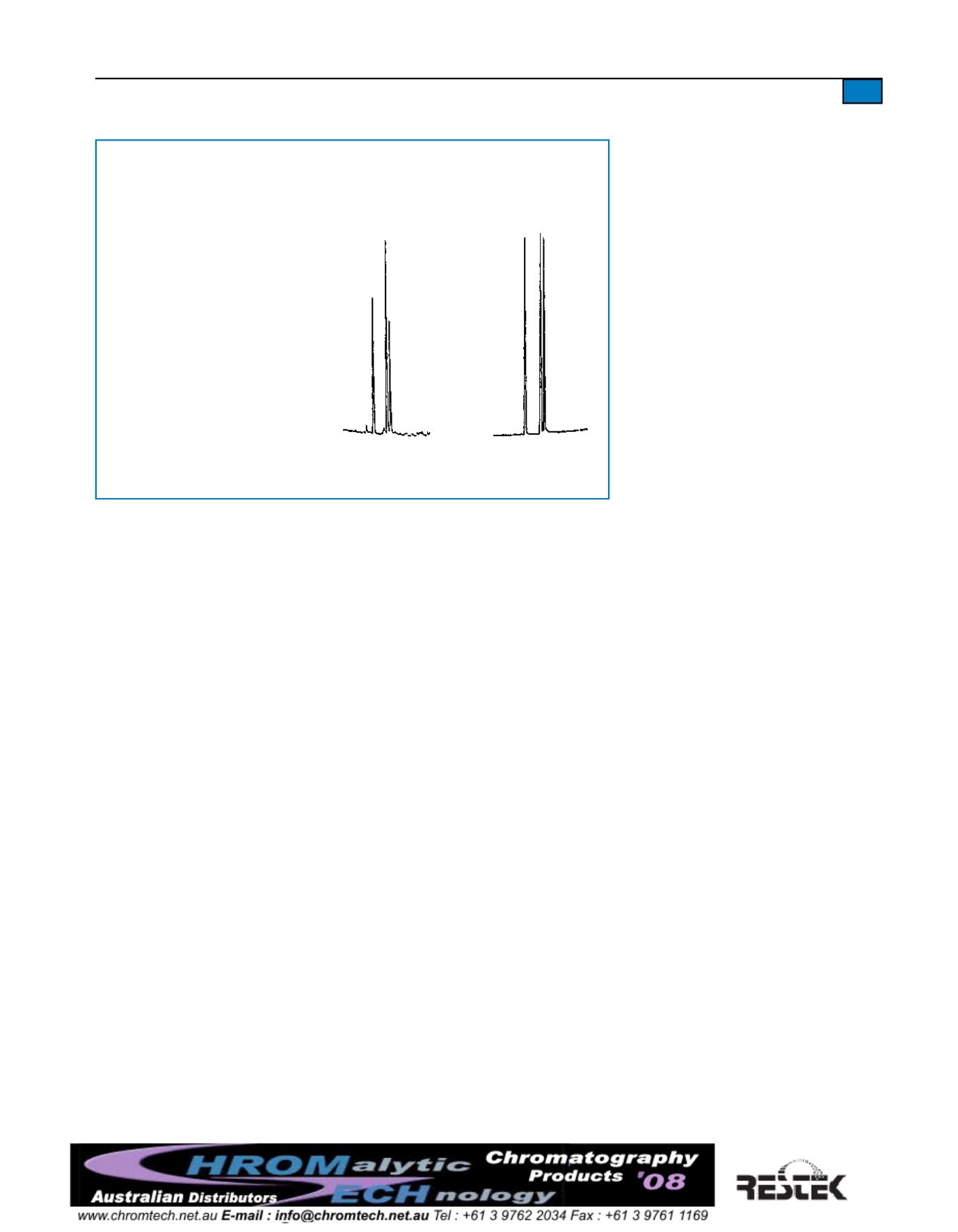

injection port before reaching the column. Figure 10 shows the effect of temperature on

thermally labileTMS derivatives of fatty acids.When the injection port temperature is set at

280°C, the response for theTMS derivatives is reduced.When the injection port tempera-

ture is lowered to 200°C, the response for theTMS derivatives is comparable to triacontane

at equivalent sample concentrations. Careful optimization of injection port temperatureswill

maximize sample vaporizationwhileminimizing sample decomposition.

ActiveCompounds:

Active compounds can be problematic in split or splitless injections.

The high surface area and heat needed to uniformly vaporize the sample can cause these

compounds to break down or be adsorbed onto the surface of the injection port liner.

Deactivated inlet liners, and Silcosteel

®

-treated or gold-plated inlet seals can helpminimize

active sites in the injection port. If tailing peaks and poor response for active compounds

cannot be corrected by using properly deactivated inlet liners and treated inlet seals, other

injection techniques such as cold on-column or temperature-programmed injections should

be considered.

MolecularWeight Discrimination:

In hot vaporization injections, one injection port temper-

ature is used to vaporize all of the analytes in one sample injection. Compounds spanning a

range ofmolecular weights and boiling pointswill exhibit differences in response for equal

concentrations of analyte. Highmolecular weight, high boiling point analyteswill have a

noticeably reduced responsewhen compared to lowermolecular weight, lower boiling point

analytes. This effect ismore pronouncedwhen analyzing samples that have a broad range of

molecular weights and boiling points. Samples containing analytes that aremore closely

grouped bymolecular weight and boiling point show lessmolecular weight discrimination.

1. TMS tetracosanoate (thermolabile)

2.

n

-triacontane (stable)

3. TMS hexacosanoate (thermolabile)

15m x 0.32mm ID fused silica coatedwith

0.25µm bondedmethyl silicone

Sample: 1µLeach of TMS

n

-tetracosanoate,

TMS

n

-hexacosanoate, and

n

-triacontane in

n

-

nonane at 2ng/µLeach component.

GC: 3000 SeriesVarian gas chromatograph

with 1077 split/splitless injector, FID and

autosampler.

Split/splitless injector:

Run 1:SPI held at 280° C

Run 2: SPI held at 200°C

Carrier gas: helium at 47cm/sec.

Oven: 130° to 280°C 20°C/min. (hold 2min.)

FID: 300°C, 32 x 10

-12

1

2

3

1 2

3

Chromatograms courtesy of Varian

Instrument Co.

280°C:

Injector too hot,

thermal degradation evident

200°C:

Injector tempera-

ture appropriate, break-

downminimized

Figure 10.

TheDonike Test illustrates the importance of injector temperaturewhen a sample

contains thermally labile compounds.

✶

For customer service, call

800-356-1688, ext. 3

(814-353-1300, ext. 3)

or call your local

Restek representative.