9

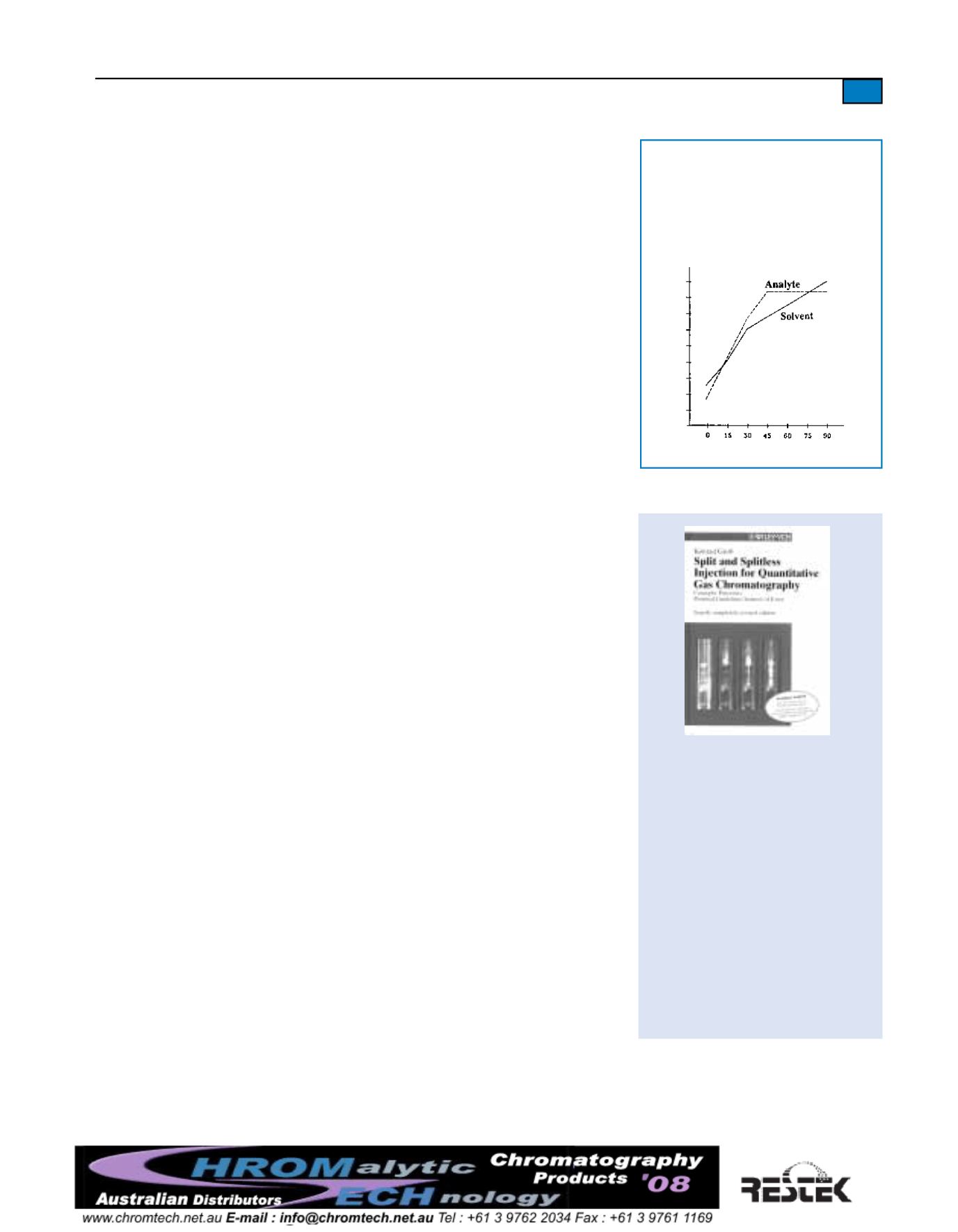

opened too quickly, responseswill be low. However, if the solenoid valve remains closed

too long, the solvent peakwill tail and peak resolutionwill suffer. To help determine the

optimal splitless hold time, a series of injections should bemade using increasingly longer

splitless hold times.When the response for the analytes of interest plateaus, the sample

transfer process has been optimized (Figure 5).

Setting the injection port temperature for splitless injections is critical, just as it is for split

injections. The injection port temperaturemust be high enough to completely vaporize the

sample, yet not so high that it causes sample degradation. This is especially important

because the residence time for a sample in the injection port during splitless injections is

longer, compared to split injections.

Solvent Focusing andAnalyteFocusing

The long residence time for samples in the injection port also affects peak shape. In splitless

injections, samples are transferred to the head of the column over a longer period of time

than in split injections.As a result, initial peak bandwidths can be very broad unless vapor-

ized samples are refocused at the head of the column. Two techniques can be used to refo-

cus vaporized samples at the head of the column: solvent focusing and analyte focusing.

The difference between the twomethods is the initial temperature of the column oven. For

solvent focusing, the initial oven temperature is low enough to allow the solvent to recon-

dense at the head of the column. This forms a zone of liquid solvent that traps all of the

vaporized sample analytes in a narrow band at the head of the column.Analyte focusing

requires an initial oven temperature that allows the solvent tomove through the column as a

vapor immediately after injection.Analytes that have a significantly higher boiling point

than the solvent are recondensed at the head of the column because of the lower oven

termperature.

A typical sequence of events for performing a splitless injection using solvent focusing is as

follows:

1.

Set the initial oven temperature approximately 20°C below the boiling point of the sam-

ple solvent.

2.

Close the solenoid valve to divert the entire sample onto the head of the column.

3.

Inject the sample and hold the oven temperature at the initial temperature to recondense

the solvent and focus the sample at the head of the column. The initial oven temperature

is typically held for the same amount of time that the solenoid valve is closed.

4.

Switch the solenoid valve to open the flow path to the split vent line and rapidly program

the oven temperature (10 to 30°C/min.) until the first analyte of interest elutes.

5.

Slow the oven program rate to enhance resolution of the remaining analytes of interest.

Figure 5.

Optimization of splitless hold time.

The splitless hold time is optimized

when further increases do not increase analyte

response but result in solvent tailing.

area

hold time (sec.)

Split and Splitless Injection in

Capillary GC, 4th Ed.

This comprehensivehandbookof split

and splitless injection techniques has

been totally revised andupdated, con-

taining information on sample evapo-

ration in the injector, matrix effects,

and a new chapter on injector design.

It also includes a CD-ROM contain-

ing visualization of the evaporation

process during split and splitless

injection.

K. Grob,Wiley-VCH, 2001, 460pp.,

ISBN 3-527-29879-7

cat.# 20451 (ea.)