6

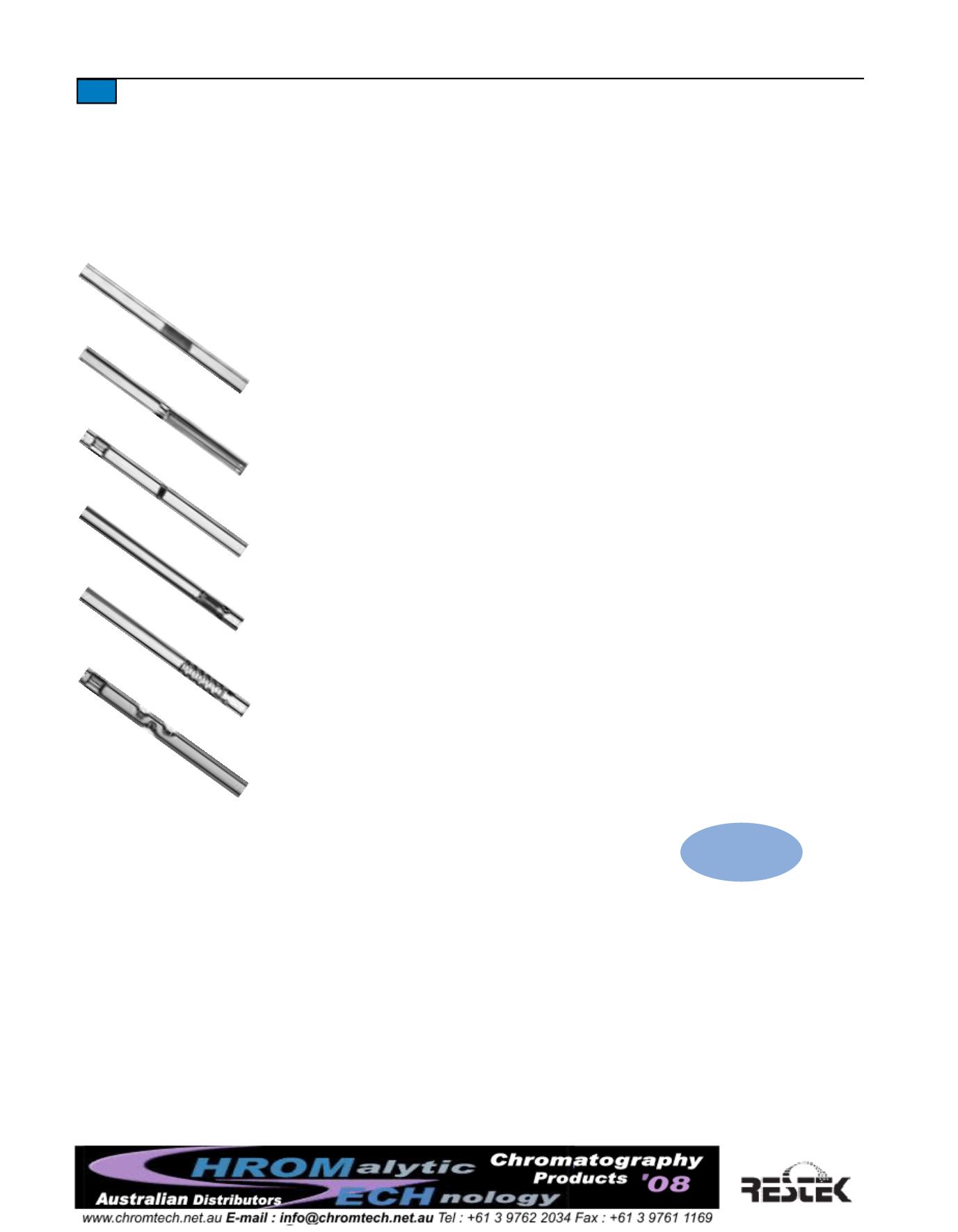

Inlet Liners for Split Injections

Split liners are designedwithmixing chambers and tortuous flow paths, to fully vaporize the

sample into a homogeneous vapor cloud before it reaches the split point.All Restek split lin-

ers are fully deactivated using a high-temperature silanizing reagent. This caps surface

silanol groups so active compounds in the sample do not degrade or adsorb onto the hot

glass surface.

To trap non-volatile residue and prevent column contaminationwhen analyzing dirty sam-

ples, pack split linerswithwool, CarboFrit

™

packing, or fused silica beads. Some of the

more commonly used inlet liners are described below.

A) Split Liner withWool

The wool provides a large surface area to allow

rapidvaporizationof the sample anddeliver a uni-

form vapor cloud to the split point. The lowmass

of thewool fiber promotes complete vaporization.

Benefits:

•

Low cost.

•

Reproducible performance.

Drawbacks:

•

Wool can be adsorptive, especially if fibers are

broken.

•

Highmaintenance requirements.

B) Laminar Cup Splitter

The sample flows through a small opening and en-

counters the head of the elongated glass cup. It

then travels around the outside of the elongated

cup before the flow is inverted twice. Larger vol-

ume injections are possible because the liquid is

trapped at the inner base and cannot escape until

vaporized.

Benefits:

•

Recommended by chromatography expert

Dr. KonradGrob

1

.

•

Best splitter liner for highmolecularweight

compounds.

•

Laminar flow profile provides highest

resolution.

Drawbacks:

•

Costly.

C) Frit Splitter

The samplemust pass through the porous ceramic

frit. The high surface area and tortuous flow path

ensure complete vaporization.

Benefits:

•

Traps septum particles and residue.

Drawbacks:

•

Ceramic frit can be active.

•

Difficult to clean.

D) Cup Splitter

The sample flows through a mini funnel and en-

counters a glass cup. The flow path then inverts

twice before reaching the split point.

Benefits:

•

Tortuous flow path aids in sample vaporization.

•

Minimizesmolecularweight discrimination.

•

Can be packedwithwool to trap particles.

Drawbacks:

•

Difficult to clean.

E) Cyclosplitter

®

(Patent #: 5,119,669)

This patented design incorporates a cylindrical

glass spiral in the sample pathway, providing a

large area for sample vaporization.

Benefits:

•

Ideal for dirty samples.

•

Allowsmany injections of dirty samples before

cleaning is required.

•

Easy to clean.

Drawbacks:

•

Not recommended for large volume injections.

F) Baffle Splitter

The baffle induces turbulent flow that directs the

sample against thewall of the glass liner.

Benefits:

•

Reproducible performance.

Drawbacks:

•

Prone tomolecularweight discrimination.

•

Septum particles and residue can enter column.

•

Subject to incomplete vaporization.

1

“InjectorsProvidingCompleteSampleEvaporationAbove theColumnEntrance inVaporizingGC Injec-

tions,”K. Grob andC.Wagner,

HRC&CC,

Vol. 16, p. 429.

A

B

C

D

E

F

010 %

deactivated

all liners are

See page 17.

All Restek liners are deactivated to prevent

adsorption of active compounds. Call for

information on custom deactivations.