7

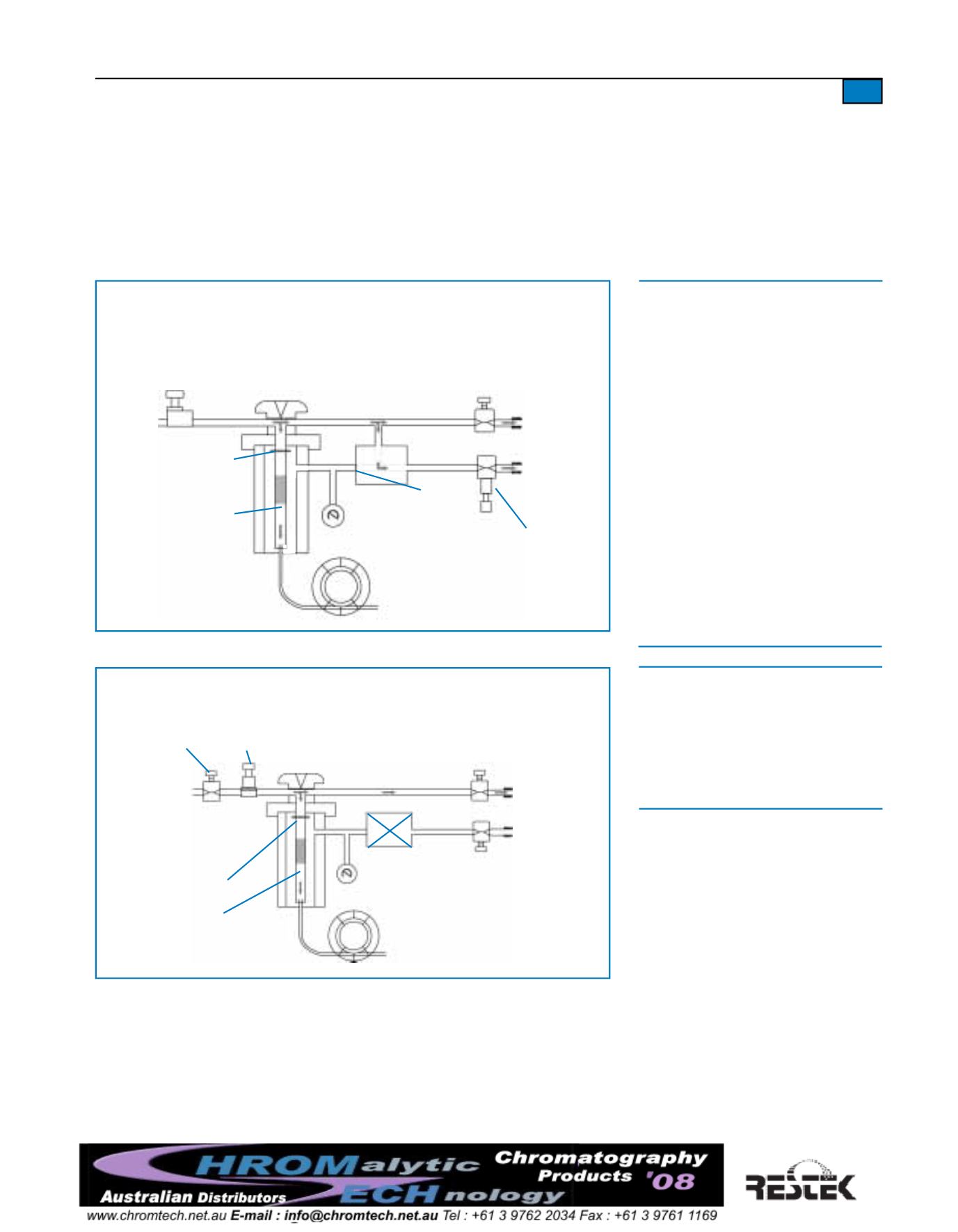

Figure 4.

Splitless injection flowpaths in a typical headpressure-regulated system.

throttling

valve

carrier inlet

injection port

o-ring or

ferrule

injector

liner

solenoid

valve

needle

valve

septum

purge vent

split vent

pressure

regulator

needle

valve

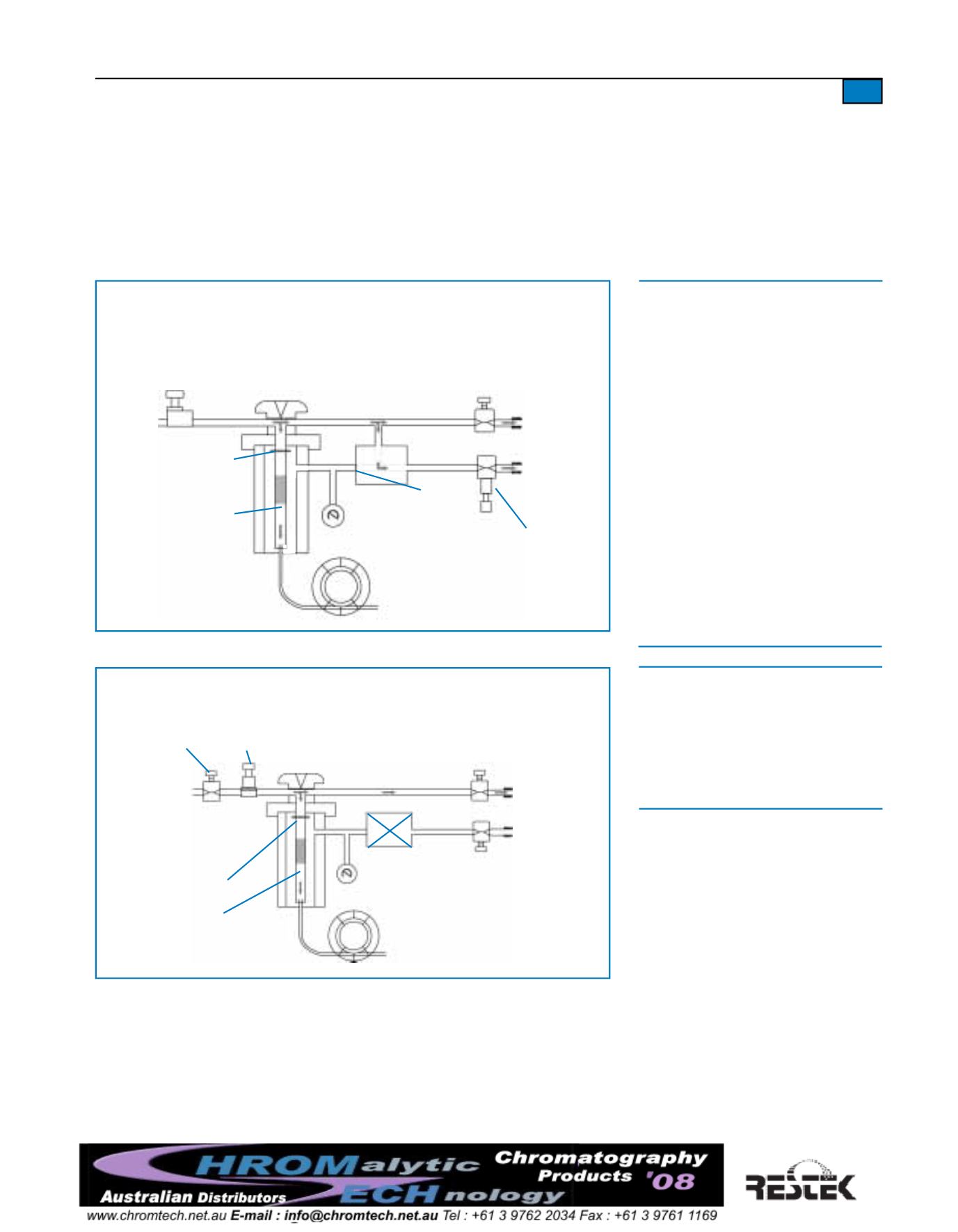

Figure 3.

Splitless injection flowpaths (injector purge off) in a typical

flow-controlled/backpressure-regulated system.

flow

controller

carrier

gas

inlet

injection

port

o-ring or

ferrule

injector

liner

3-way

solenoid

valve

needle

valve

septum

purge vent

split vent

backpressure

regulator

closed

Figure 3.

• Solenoid valve closed between injector

and split vent: only column flow enters

injector; column flow passes into column.

• Needle valve at septum purge vent allows

only septum purge flow to exit septum

purge vent: most of carrier gas diverted

through solenoid valve, out through split

vent.

• Sample vapor in injector liner can exit

only to column, mixedwith column flow

of carrier gas.

• Solenoid valve switched to establish

flowpaths as in split injection: sample

vapor remaining in injection port swept

out of split vent.

• Splitless hold time determined by sample

composition.

to detector

analytical

column

Figure 4.

•

Solenoid valve closed: entire carrier gas

flow and entire sample directed onto

analytical column.

•

Carrier gas flow rate into system reduced

to enable entire flow to pass through

analytical column.

to detector

column

closed

Operating in the Splitless InjectionMode

When operating in the splitless injectionmode (Figures 3 and 4), the solenoid valve is

switched, changing the flow path of the carrier gas.At the beginning of a splitless injection,

the solenoid valve is set to prevent the flow of carrier gas from the injection port body through

the solenoid valve.When the solenoid valve is in this position, only the column flowmoves

through the injection port liner. Column flow rate is determined by the pressure of the carrier

gas in the injection port as set by the pressure regulator and the analytical column dimensions.

After a carefully determined time (the splitless hold time) the solenoid valve is switched to

re-establish the flow paths as used in the split injectionmode. This allows any vaporized

sample remaining in the injection port to be quickly swept out of the injection port liner

through the split vent.A typical splitless hold time is between 60 and 90 seconds. The ideal

splitless hold time is long enough to allowmost of the vaporized sample in the injection

port liner to be transferred to the analytical column. Excessively long splitless hold times

can produce tailing peaks and broad peaks. The splitless hold timemust be determined

through experimentation, andwill vary according to sample composition, column length and