12

SeptumPurge Optimization

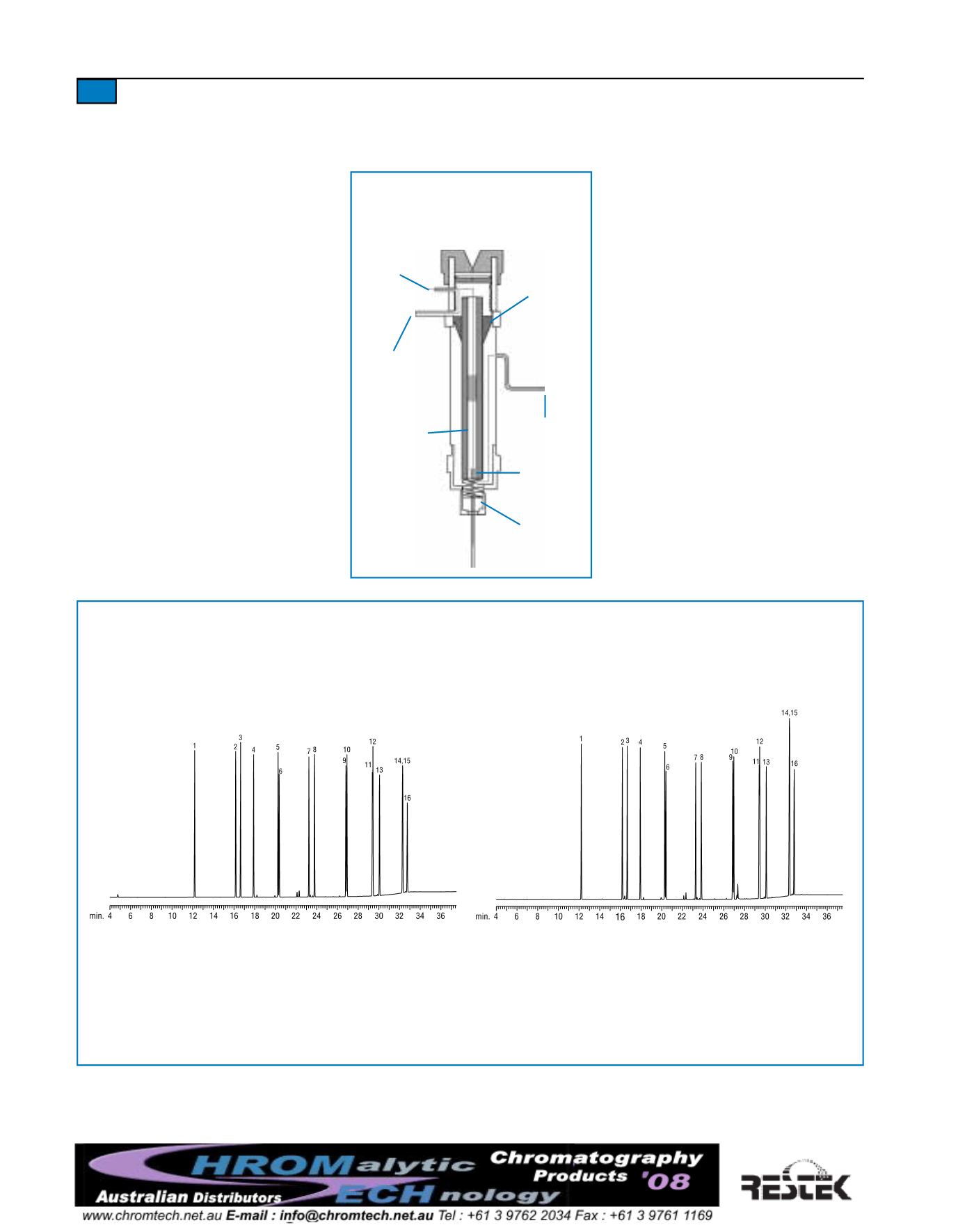

The septum purge (Figure 8) serves two func-

tions: to sweep septum bleed volatiles out of

the system and to reduce the potential for

sample backflash contaminating the carrier

gas inlet line. Optimization of the septum

purge flow rate is important, especiallywhen

the inlet is operated in the splitlessmode.

Most GCmanufacturers recommend that the

septum purge flow rate be set between 3 and

5cc/min. Flow rates exceeding 5cc/min.

should not be used because highly volatile

sample components could be preferentially

purged from the inlet liner buffer volume after

vaporization. Flow rates lower than 3cc/min.

can allow septum bleed to enter the inlet liner

and cause ghost peaks to appear on the chro-

matogram.

The septum purge flow ratemust be readjust-

ed each time the injection pressure is changed

bymore than 5psig.Most GCs have a low-

flow needle valve that makes septum purge

adjustments easy.

Figure 8.

Typical carrier gas flowpath in a

Varian split injector.

septum purge

out

carrier gas in

split liner

column

spring

split point

split vent out

ferrule

GC_EX00600

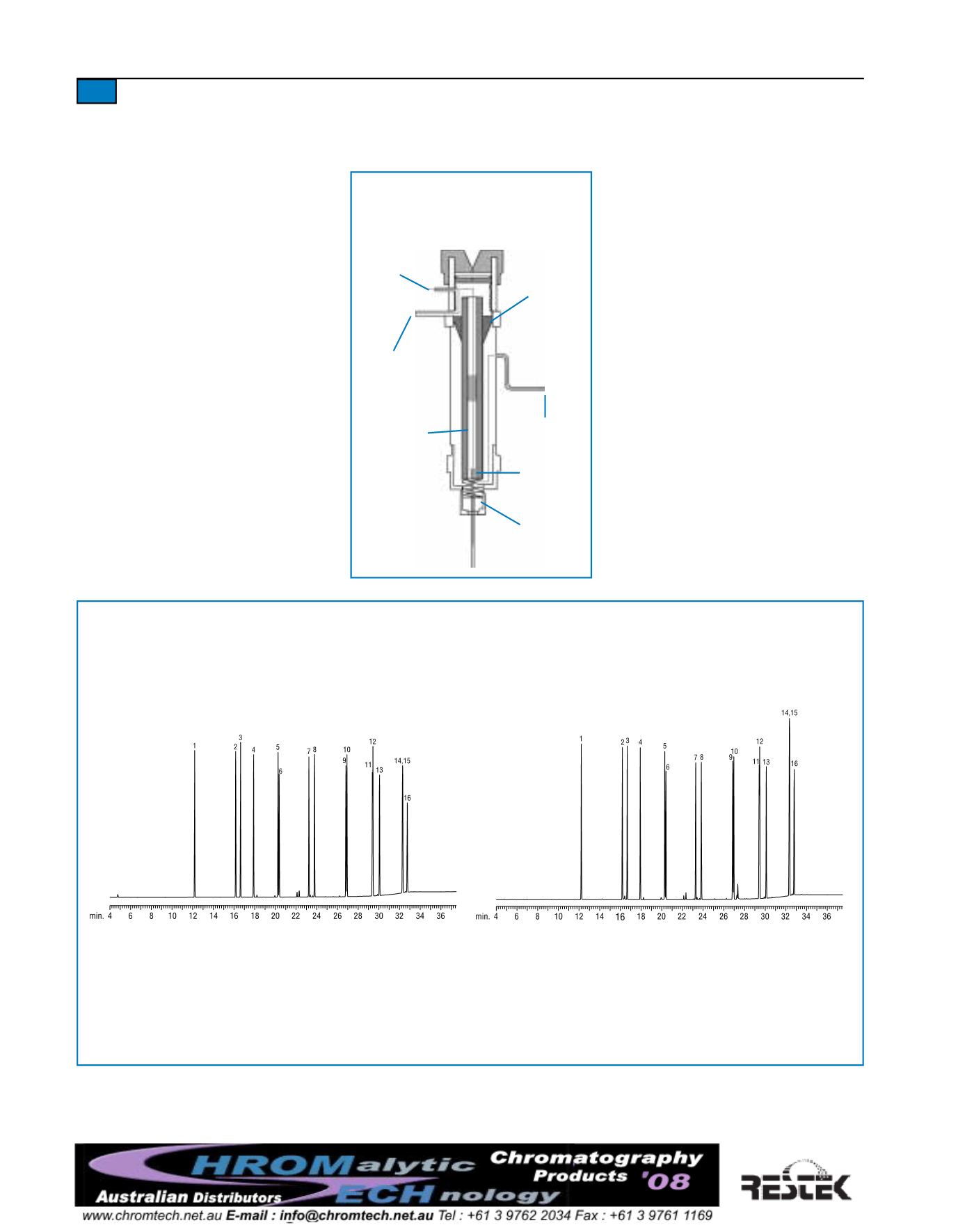

Rtx

®

-5 15m, 0.32mm ID, 1.50µm (cat.# 10266)

Sample:

50µg/mLPAH standard (cat.#31011 ) in hexane

Inj.:

1.0µLsplitless (hold 2min.),

4mm single gooseneck inlet liner w/FSwool (cat.# 22405)

Inj. temp.:

200°C

Carrier gas:

helium, constant pressure

Linear velocity: 76cm/sec.@ 40°C

Oven temp.:

40°C(hold 4min.) to 325°C@10°C/min. (hold 5min.)

Det.:

FID@350°C

Figure 9.

Injector temperature affects the recovery of highermolecular weight compounds.

GC_EX00601

1. naphthalene

2. acenaphthylene

3. acenaphthene

4. fluorene

5. phenanthrene

6. anthracene

7. fluoranthene

8. pyrene

9. benzo(a)anthracene

10. chrysene

11. benzo(b)fluoranthene

12. benzo(k)fluoranthene

13. benzo(a)pyrene

14. indeno(1,2,3-cd)pyrene

15. dibenzo(a,h)anthracene

16. benzo(ghi)perylene

Injector temp: 300°C

Injector temp: 200°C